Here are some final drive motor horrors from our own shop -- with some explanations of what caused them and how you can prevent them.

And while you're here, check out these terrifying Shop Talk Blog posts from the past ...

Completely Clogged!

If your case drain filter looks like this, you may have much more damage on the inside. This filter is severely clogged with contamination. The good news is that the filter caught this debris before it went downstream. The bad news, however, is that this level of clogging will cause a pressure buildup in your final drive. Pressure build-up like this can lead to extensive, usually irreparable damage -- imagine having the cover plate of your final drive motor rocket off at incredible speeds in the middle of a critical job.

Keep your eyes open for more examples further on in this post.

Destroyed Rotator Group on a Final Drive

Pressure buildup, failed bearings, and devastating bearing failure can lead to very problematic issues in a final drive motor.

This axial piston final drive has catastrophically damaged rotator group. You can see some piston shoes torn off and others seriously mutilated beyond repair. And don't forget the damage we can see to the pistons, the barrel, and the retainer plate. This damage is not something that can be fixed and probably started with a clogged case drain filter that went undetected until the drive motor was totaled.

Check those case drain filters -- we cannot emphasize this enough. Extreme pressure buildup on the return line or case line can blow components out of place, and when they come loose, other parts are wrecked -- and all that contamination will begin to compound the damage.

Excessive Wear on a Radial Piston Hydraulic Motor

A loss of power and productivity on a radial piston hydraulic motor can be excessive wear on components. In particular, one source can be the radial pistons.

Looking at the middle piston below, you can see what a brand new piston should look like, The one on the left is normal wear and tear, while on the far right we can see where significant metal has been lost. No doubt the productivity of the final drive was seriously compromised. All this metal has to go somewhere, which is an excellent example of where generated contamination begins. It also reminds us of the importance of replacing hydraulic filters regularly.

Chewed-Up Main Bearing in a Final Drive

Has your drive motor started making some grinding sounds, vibrating far more than usual, or isn't as powerful as it should be?

You might want to check the bearings, focusing primarily on the main bearing. Even the highest quality bearings will eventually fail, and if they are ignored long enough then, catastrophic damage can result.

This is what's left of the main bearing in a final drive motor. The first picture shows you how severe the damage looks up close, and the second provides an overview of how extensive the damage is.

And this again reinforces the need to flush your hydraulic system (and change your hydraulic filters) after a catastrophic final drive motor failure. You don't know how far into your hydraulic system the metallic debris may have gone, or how many filters it may have clogged.

Radial Piston Hydraulic Motors Cylinder Block Issues

Here's a damaged cylinder block of a radial piston hydraulic motor. Not only does it show signs of abnormal wear, one of the cylinders is now in the wrong way. Just imagine your final drive motor trying to function with one of the cylinders turned sideways -- and how much damage resulted while it tried to run. Never ignore new sounds or vibrations in your final drive motor. It can easily be a problem that will total your drive and cost you a significant amount of money.

A Spline With No Teeth

Does your hydraulic motor spin but you don't go anywhere?

That can be a bit of a puzzle, but we've worked on motors with that problem -- and one of the more interesting ones is shown below. This axle had its spline teeth worn down so much that it simply couldn't be engaged. No matter how fast the motor spun, the machine just sat there. Fortunately, this is a simple repair. However, it might be wise to see if other components are this worn. And if they aren't, then you need to find out why.

Seriously Worn Planetary Gear Hub

This gear hub has been through some stuff, to say the least. The posts seem to be chewed up, rust is present, and so many of the surfaces look like they've been haphazardly ground by a drunken machinist.

The cause of this type of damage, however, is going to be severely contaminated gear oil combined with a failed seal. When the seal fails, gear oil can leak out of the planetary hub, resulting in metal-on-metal contact and surface damage. That adds to overall contamination levels. Then combine what with abrasive materials and moisture that can make its way passed the damaged seal and you have a recipe for disaster.

Believe it or not, most of this damage can be repaired by a team of highly skilled welders and machinists. The same can't be said for other parts within the gear hub.

Dirt in the Gear Oil??

If this is what we see when we open up your gear hub, we know it's not good. This can be prevented by (1) replacing seals when they start to look questionable and (2) checking and changing out the gear oil per manufacturer recommendations. Contamination at such levels can cause serious damage to the planetary hub and indicates to us that you've been lax in maintenance.

Case Drain Pressure Destruction

Earlier we mentioned that there would be some more examples of the potential damage caused by a clogged case drain filter -- and here's one of those examples.

By the time your cover plate cracks or starts disassembling itself, we can guarantee that there is serious damage within. And to make things worse, all of this catastrophic damage could have been prevented by replacing the case drain filter when you replace the other filters in your hydraulic system. Please remember to replace case drain filters if your machine has them!

And just as a reminder, this is what a clean inline case drain filter should look like. And the cost + time of replacing them is going to be far less than what you'd spend repairing the damage from neglecting them.

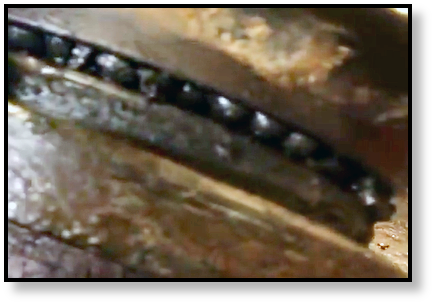

Main Bearing: I See You!

You should never be able to see the ball bearings in the main bearing from the outside of your final drive motor, nor should you see that its race is missing. No doubt there were some strange noises coming from the final drive, and it probably started running very hot.

These are anti-friction bearings and are supposed to reduce friction. If they're in this condition, however, they are causing even more friction. At significant speeds and torque, heat is going to be generated. Needless to say, this bearing must be replaced. But there's still a question: how on earth did this happen?

The most likely culprit is a lack of undercarriage maintenance. Excessive debris built up in the undercarriage and around the final drive to the point that it pushed the face seal out of place. Once that critical seal was compromised, debris began collecting around the main bearing. Over time, it became packed so tightly that things started getting pushed out of place.

This expensive damage could have been prevented by regularly cleaning out the undercarriage. Undercarriage maintenance is far more important than many of us realize and doesn't have to be a major task when attended to daily.

Drive Motor Seal Gone Bad

Leaking fluid, whether gear oil or hydraulic fluid, is bad for your final drive motor. If lubricant makes its way out, all kinds of contamination can make its way in.

The cause of leaked fluid is going to be a failed seal. Now, all seals have a limited life space -- they simply will not last forever. Replacing them in a timely manner once a leak is detected is very important. Neglecting them, on the other hand, can lead to what you see below.

This seal isn't only allowing fluid to escape your drive motor, but is generating damaging contamination on its own.

Needle Bearings in Unusual Places

Grinding, vibration, and hardly any power may be caused by worn or severely damaged bearings, such as the one shown below.

That is not where you want to see the remains of needle bearings -- you should see them in an anti-friction bearing assembly. When you find them where they don't belong, you can be sure that there is serious damage elsewhere.

Conclusion

The worst damage that we've encountered on final drive motors can be prevented through regular maintenance.