Good final drive repairs not only fix what went wrong, but they track down why it went wrong in the first place. Is the company that you entrust your final drive to this careful?

Here are a few other Shop Talk Blog Posts you might enjoy.

- 10 Step Final Drive Reman Process

- 6 Ways to Sabotage Your Final Drive

- 2-Phase Testing and Quality Assurance

What is Root Cause Analysis?

Root cause analysis refers to the process of identifying the root cause of a problem rather than just addressing the symptoms. Put another way, it means tracking down the origins of a problem. It can be used for problem-solving in many different areas, from the complexity of telecommunications systems to find out why your final drive motor failed.

The Process Behind Root Cause Analysis

There are several different ways to approach root cause analysis, but this one from FTMaintenance applies directly to mechanical repairs:

- Consider every possible case

- Gather additional information and evidence

- Identify the factors that contributed to the problem

- Analyze all the data to identify the root cause

- Figure out how to keep it from happening again

Notice #5: the job isn't done until we've figured out a way to keep it from happening again.

1. Consider every possible case

A hydraulic repair shop should employ technicians with experience and training to be familiar with the most common causes of final drive motor failure. And consider every possible case also means recognizing the external factors that can cause drive motor issues.

Suppose your final drive seems weak. Here are some possible causes:

- Weak charge pump

- Lack of hydraulic pressure

- Track tension set too tight

- Final drive stuck in high-speed mode

- Premature wear due to contamination or lack of lubrication

- Normal wear and tear

2. Gather additional information and evidence

To help the root cause of failure, the more information you can provide about what was going on when your final drive failed, the better. What may seem insignificant to you could be the key to getting your drive motor back ASAP.

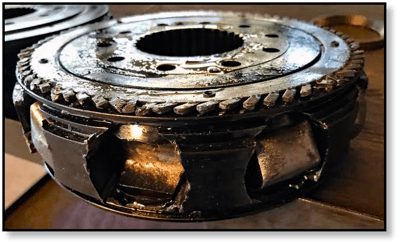

No one would argue that this is a serious mess, but where did it all start?

Hydraulic repair shops will clean your drive motor, open it up, clean the parts, and perform a detailed inspection of every part. A good repair shop won't stop with the first thing they find wrong, either. Everything will be checked according to strict inspection standards. And the results of that inspection will be documented, including information about the severity of the damage.

3. Identify the factors that contributed to the problem

There's a lot of factors that can contribute to failure. While inspecting parts and looking at the overall condition of a final drive motor, technicians start putting together a picture of what happened. But good ones don't identify a root cause until they've looked at everything -- and sometimes the drive motor isn't even the problem. To complicate things further, there can be multiple issues that together contributed to a failed final drive.

This damage was traced back to some serious contamination issues.

4. Analyze all the data to identify the root cause

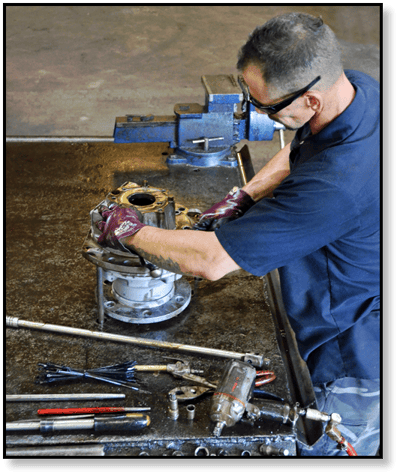

Once everything has been inspected, technicians start putting all the pieces together to get an overall picture of what went wrong. They don't settle for just addressing what happened but keep looking until they find out why it happened. And that's also why it's important to have experienced techs on staff.

Just disassembling a travel motor is hard work.

Just disassembling a travel motor is hard work.

5. Figure out how to keep it from happening again

A quality shop for repairing final drive motors will also advise you on how to keep those problems from happening again. They take the time to come up with a plan of action that goes beyond repair. Maybe you need to change out the gear oil more often, keep a closer eye on the case drain filters, or it could be that it was just wear and tear.

Conclusion

Here at Texas Final Drive, we follow these same steps to make sure our repairs are of the highest quality. And even though it might not be good for our business, we want to help you keep your drive motors from failing again. We'll even give you advice over the phone!