What makes a final drive motor different from a hydraulic motor is the planetary gear set on the drive motor--and when the gears go out, you're going to have major problems.

Here are a few Shop Talk Blog posts you might like:

- What's Wrong With My Final Drive?

- Facts You Need to Know About Bearings and Final Drive Motors

- Troubleshooting Five Common Final Drive Problems

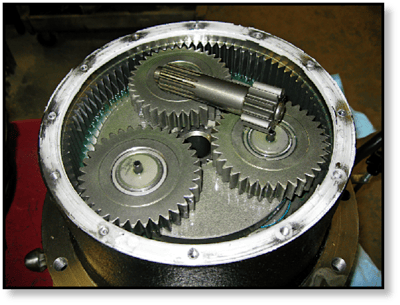

The planetary system on your final drive takes the speed generated by the hydraulic motor and transforms it into the torque needed to move your machine. That involves some high forces and high stresses on the gear teeth and splines in your planetary hub, which is why gear damage is an important topic.

Normal Gear Wear

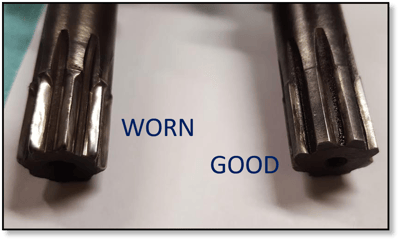

Over time, your gears will eventually wear out. For example, excessively worn gear teeth end up looking pointed at the tips. That makes it much harder for a planetary final drive to transfer forces and torques, and will inevitably lead to some power losses. Sometimes the teeth become so worn down they just spin and accomplish nothing. Wear and tear is normal, but there is such a thing as accelerated wear.

Gear Oil Issues

There are various things that can cause your gears to wear out prematurely, but several of them have the same thing in common: gear oil.

If gear oil levels are allowed to drop too low, then there's a strong chance that all your gears won't be lubricated appropriately when they're trying to run. That means that the gear teeth will be making direct contact with each other without the protection of gear oil and its EP (excessive pressure) additives. This kind of contact can cause serious damage to the surface of the gear teeth.

If you've got old gear oil in your planetary hub, that can create a thick sludge that worsens matters. Key additives that make gear oil well adapted to the high pressure, high force environment of a planetary gear system. A thick sludge forms, some components may end up coated in a disgusting film, and all that results in more damage.

Pitting

Pitting is also a major problem for gears, and it forms due to cycle contact stress. Cyclic contact stress can best be described as forces acting on the surface of the gears that vary over time. If pitting is present, it can usually be spotted on the bottom portion of the gear tooth (i.e., between the tooth root and pitch line), where meshed teeth slide against each other.

There is a two-fold problem with pitting. First, it damages the surface of the gear teeth, where they slide against each other. Second, the material removed during pitting contaminants the gear oil, causing more issues. One of the best ways to minimize pitting is to use the right type of gear oil and change it out regularly.

Damage Due to Contamination

Another source of problems is particle contamination in the gear oil. Tiny fragments of sand, dirt, and other abrasive materials can become trapped between surfaces that make contact. Even if there is gear oil present, surface damage can still occur.

There are already high stresses acting on the gear teeth. The presence of something hard and abrasive between those teeth as they turn means that the surface stresses will multiply in that area. That can lead to scratches, gouges, and much faster wear. Keeping the gear oil clean and addressing leaks right away can go a long way in preventing contamination.

Scoring/Scuffing

Scuffing (or scoring) is an interesting type of wear. It's categorized as adhesive wear because metal particles actually move from the surface of one gear to another. This occurs when the gears make contact and slide over each other without enough lubricant present. The best way to prevent scuffing on gear teeth is to use the right kind of lubricant, keep the gear oil levels where they should be, and change the gear oil regularly.

Cracks and Bending Fatigue

The surface of gear teeth and splines aren't the only thing that can fail. Cracks can develop at the root of the gear teeth as well as the end of the gear teeth or on the profile of the teeth. Even though they may seem tiny and inconsequential, those cracks can literally travel at the speed of sound when they suddenly grow. This type of damage results from fatigue, a combination of mechanical stress and time. More specifically, they result from bending fatigue, where the gear tooth bends during operation.

Fluctuating loads often occur when the bearings are misaligned, either because of incorrect installation or because they've become worn out. Many people don't realize that a worn-out bearing is going to have more clearance and play that can affect how well the gear teeth mesh together.

Conclusion

Most premature gear failure in the planetary hub can be prevented by ...

- Maintaining the gear oil (check and change)

- Replacing leaking seals

- Installing the bearings so they are correctly aligned

- Replacing bearings when they've worn out

Taking the time to add these steps to your normal maintenance can help your gears last and run efficiently.