Every hydraulic motor, final drive, and travel motor is going to have bearings. Those bearings are a key component in its design and vital to its efficient operation. When bearings fail, quickly take out other parts and can render a hydraulic motor irreparably damaged. In this Shop Talk Blog post, you will learn key facts that you need to know about bearings and final drive motors.

Here are a few other blog posts you might want to take a look at ...

Fact #1: The Purpose of Bearings

- Maintaining the position and alignment of shafts and gears

- Reducing friction

- Transferring loads

- Reducing wear and tear on other components

When the bearings can no longer perform these tasks, things go wrong very quickly.

Fact #2: Number One Cause of Bearing Failure

Experts agree the number one cause of bearing failure is contaminated lubricant. When lubricant, whether its gear oil or hydraulic fluid, is contaminated with particulate matter (such as sand, metal flakes, etc.), water, air, or simply degraded, it no longer functions properly. It failes to adequately protect contacting surfaces. When those surfaces come into contact while undergoing high forces, they are going to be damaged. This leads to pitting, flaking, cracks, and other forms of damage. That, in turn, leads to additional contaminants present in the lubricant. In short, it begins a devastating cycle of damage.

For a dramatic example, consider the travel motor shown below. It came from a Bobcat T180/T190 and its failure was traced to a main bearing. This level of damage cannot be repaired. The customer’s only option was to replace the travel motor.

Other causes of bearing failure include insufficient lubrication, improper handling before installation, and improper mounting. Remember: if the bearings are not mounted correctly, they will not work correctly and can do far more damage than good. If you aren't sure you know how to install a bearing correctly, it might best be left to a professional.

Fact #3: Signs that Bearing Failure is Imminent

One of the signs of bearing failure is noise or excessive vibration coming from the final drive. If your final drive is overheating (water steams when it come in contact with it), that can also be caused by a failed bearing. These kinds of symptoms should never be ignored! If you disassemble your final drive, you can carefully clean your bearings and inspect them for signs of damage. Look for things such as pitting, cracking, flaking, wear tracks on the outer race, or damaged/broken balls or rollers. These are all signs that you need to replace the bearings.

Fact #4: How You Can Prevent Premature Bearing Failure

The first step to preventing premature bearing failure is to check the level of gear oil in your final drive on a regular basis, per manufacturer’s recommendations. That will take care of the bearings on the planetary side of the final drive or travel motor. We recommend changing the gear oil out about once a year, too.

The first step to preventing premature bearing failure is to check the level of gear oil in your final drive on a regular basis, per manufacturer’s recommendations. That will take care of the bearings on the planetary side of the final drive or travel motor. We recommend changing the gear oil out about once a year, too.

Because most bearing failures are the result of contaminated lubricant -- which includes both gear oil and hydraulic fluid -- be careful not to introduce contamination to your system. That also means that you need to attend to leaks quickly. If fluid can leak out, other things can get in.

Next, don’t mix different brands of gear oil (or hydraulic fluid, for that matter). Not all lubricants are compatible with each other, and mixing them can cause them to lose the key characteristics that make them good lubricants. When you add a new type of lubricant, make sure that you drain as much of the original out of the system as you can.

Finally, don’t abuse your equipment. Use common sense. Stay within the limits of your machine. If you abuse it, it will wait until the most inopportune time to fail as part of its revenge.

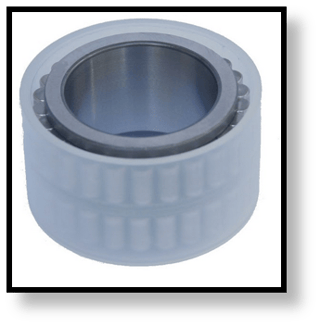

Fact #5: Types of Bearings in a Final Drive

In a final drive hydraulic motor, there can be several different types of bearings. Bearings are used for holding gears, drive shafts, and other components in place. The type of bearing used depends on several things, including the type of loads involved. You are likely to find plane bearings (also known as bushings) as well as anti-friction bearings. Anti-friction bearings include roller bearings, ball bearings, needle bearings, and tapered bearings.

Conclusion

Final drive bearings keep components aligned and in the right position, reduce friction, transfer loads, and reduce the wear experienced by other parts. In order to do that effectively, they need to be properly lubricated -- and contaminated lubricant is the number cause of bearing failure. If you notice your final drive making unusual noises, vibrating excessively, or overheating, then you may have a bearing that is going out. You can prevent bearing failure by checking lubrication levels, using the correct lubricant, not combining different types of lubricants, and not abusing your equipment.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.