Final Drive Gear Oil

Have you ever looked at the specifications for gear oil and wondered what all those values really meant? Considering how important gear oil is to your final drive motor, its always good to know as much you can. In this blog post, we are going delve into the sometimes confusing but always interesting world of gear oil characteristics!

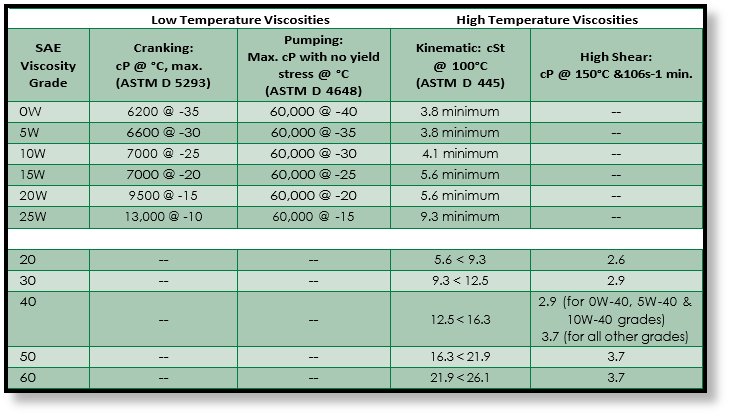

SAE Viscosity Grade

If you have worked around machinery for very long, you are probably already familiar with the SAE Viscosity Grade and what it means, but a little review never hurt anyone. The SAE designation provides two numbers representing viscosity, such as 80W-90. The W designation stands for "Winter Viscosity Grade" and it means that the viscosity was tested at a colder temperature. The numbers without a W were tested at about 210 F, which is considered close to the operating temperature of an engine. For an SAE 80W-90, the 80 is the winter viscosity grade and the 90 is the standard grade.

If you have worked around machinery for very long, you are probably already familiar with the SAE Viscosity Grade and what it means, but a little review never hurt anyone. The SAE designation provides two numbers representing viscosity, such as 80W-90. The W designation stands for "Winter Viscosity Grade" and it means that the viscosity was tested at a colder temperature. The numbers without a W were tested at about 210 F, which is considered close to the operating temperature of an engine. For an SAE 80W-90, the 80 is the winter viscosity grade and the 90 is the standard grade.

To find the actual viscosity associated with the numbers, you can refer to a SAE viscosity grade chart or table. Note that gear oils have a different viscosity table than standard automotive motor oils or crankcase oils, so using a grade table for gear oils you would discover that 80W a minimum viscosity of 7.0 cSt and the 90 would correspond to a minimum viscosity of 13.5 cSt. As expected, the gear oil is less viscous at higher operating temperatures.

Gear Oil Color

The gear oil color characteristic is rather interesting because it associates the color of the oil with a number. When the test is performed (using ASTM D1500), the color of the oil is compared to a glass slide. Here's a description from MachineryLubrication.com ...

"This test is used in lubricant manufacturing for quality-control purposes. It is performed using a standard light source to match a sample to a glass slide. Values for the glass range from 0.5 to 8.0 in 0.5 increments. If the sample falls between two colors, the higher number is reported. If no color gauge is available, the oil color is compared to a previous sample or a new oil sample."

Colors can range from opaque to transparent, and changes in the color of oil can signify problems such as oxidation or contaminants.

Gear Oil API Gravity

API gravity is similar to specific gravity in that it compares the weight of the oil to the weight of water but uses a different reference system, so to speak. If the API gravity is greater than 10, then the oil is lighter than water and will float on top of it; if the API gravity is less than 10, then the oil is heavier than water and will sink. The API for a gear oil is determined according to ASTM D287.

Viscosity of Gear Oil

The viscosity of a fluid is a measure of how much a fluid resists deformation; in simpler terms, its a measure of how "thick" a fluid is, or how difficult it is to pour. It is the most important physical property of a lubricant, and affects how well that lubricant performs including film thickness, film strength, final drive life expectancy, and final drive efficiency. This property is determined using ASTM D2983 (Brookfield low temperature viscosity) and ASTM D445.

Viscosity Index

The viscosity index (VI) is a unitless number that was empirically derived. Its purpose is to provide a measure of the variation of viscosity with temperature. The higher the VI, the more stable the lubricant's viscosity is going to be across a wider range of temperatures. The VI is determined according to ASTM D2270.

Flash Point of Gear Oil

According to Engineering Toolbox, the flash point is "the lowest temperature where enough fluid can evaporate to form a combustible concentration of gas." It serves as an indicator of how easily a chemical (in this case, gear oil) can ignite and burn. The typical flash point of gear oil indicates that it is not very hazardous. The flash point is typically obtained in accordance with ASTM D92.

Pour Point of Gear Oil

The pour point of an oil is the temperature at which is becomes semi-solid and difficult to pour. In short, when an oil is cooled below its pour point, you are going to have a hard time pouring it. This value is usually determined in accordance with ASTM D97. Note that lower pour point values are used for applications that involve lower temperatures.

Channel Point of Gear Oil

Channel Point of Gear Oil

Here is an excellent explanation of the channel point taken from Certified Labs:

"When a gear passes through the gear oil, the oil flows in behind it filling in the channel left by the gear. This method records the temperature at which the gear oil no longer flows back into the channel."

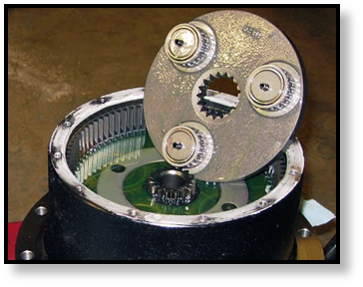

Gear Oil and Final Drives

It's very important to check and change your gear oil according to manufacturer recommendations. Failure to do so will cause expensive damage to your final drive motor. In addition, follow manufacturer guidelines for the grade of gear oil you use. To learn more, check out this post: The Effects of Gear Oil Contamination on a Final Drive Planetary: A Comprehensive Guide

It's very important to check and change your gear oil according to manufacturer recommendations. Failure to do so will cause expensive damage to your final drive motor. In addition, follow manufacturer guidelines for the grade of gear oil you use. To learn more, check out this post: The Effects of Gear Oil Contamination on a Final Drive Planetary: A Comprehensive Guide

Conclusion

There is actually a great deal of information contained in a typical characteristic description for gear oil, although much of it seems hidden by technical jargon. However, once the jargon is removed, its easy to see that a great deal of testing and chemistry goes into developing the gear oil that is so keep to keep your final drive motor running without a problem. These facts about gear oil are good to know, especially if you are about to fix a final drive.

Download your Free Infographic Guide on the 6 Fascinating Facts About Gear Oil provided by Texas Final Drive.