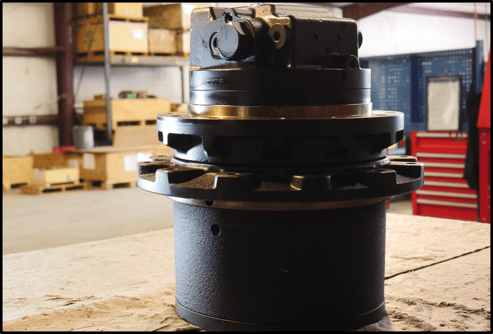

In this Shop Talk Blog post, we are going to review some hints and tips for how to repair your own final drive. We'll begin with some guidelines for installation and removal, followed by taking your final drive apart and dealing with different types of repairs.

Removing / Installing a Final Drive

Trying to remove a final drive can be challenging, and putting a new final drive on your machine can be just as difficult. You want to start by cleaning up the area where the final drive is installed. Break loose any hardened debris and try to clear out all the dirt and grime that gathers there. Then, tag your hydraulic hoses so you can reattach them to the correct ports without confusion. Some of our customers use multi-colored plastic ties, strips of colored wire, or chalk marks. There is more than one way to keep track of which hose is which, so just figure out a way that works for you.

Here is a video from one of our customers that shows the removal and installation process of a final drive from a practical perspective.

Once the final drive is removed, we recommend taking that opportunity to finish cleaning up that part of your machine. It’s also a good time to clean up any fluids that may have leaked out during operation or spilled during removal. When your new drive comes in, make sure the fittings are clean before you start attaching them to the final drive and make sure match up the hoses to the correct ports.

Be sure to add hydraulic fluid to the motor before starting it to avoid a damaging dry start. Also, do not forget to add gear oil to the planetary hub. Failure to do these two critical steps can seriously damage your motor and void its warranty. This is also a great time to replace your case drain filter if you have not already done so. If your final drive or hydraulic system has recently failed, you might want to change out the rest of your hydraulic filters.

Tips for Taking Apart a Final Drive

Before you take it apart, you will want to clean up the outside of your final drive. Get rid of the hardened debris, scaling, rust dirt, mud, sand, concrete dust, etc. That way, you will not end up contaminating the inside of your hydraulic final drive motor.

When you're ready to start disassembling the final drive motor, you may find that it's difficult to remove the cover plate. Some final drives -- especially KYB / Kayaba final drives -- make this part very challenging. You may need to make use of cheater bars and other non-standard tools in order to get your final drive opened up.

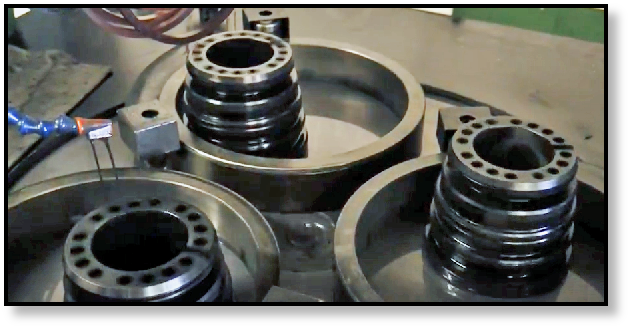

Once you do open it up, pay close attention to the order in which you remove the parts. You may need an arbor press or something similar to get the hubs apart. Keep in mind that in order to really examine some of the parts, you will need to clean them.

Certain Parts Eventually Require Replacements

There are some final drive parts that need to be replaced more often than others, including seals, the main bearings, gears and gear bearings, and the gear plate. Parts like the seals and bearings have to be replaced more often, and neglecting to do so can result in serious and expensive damage. Gears, gear bearings, and the gear plate take a great deal of abuse because of the massive forces and torques they are transmitting inside the final drive motor. When they start to fail, they do need to be replaced.

Replacing Final Drive Motor Seals

Kits for the main seals, also called floating face seals or duo cone seals, are easy to track down for most final drive motors and can usually be installed without specialized tools. However, installation of the main seal may require the use of an rubber mallet or a specialized installation tool to make the installation go easier. These seals have a limited life span and need to be replaced as soon as they start to leak.

Replacing Final Drive Gears and Shafts

If you open up the final drive and notice that your gear teeth look pointed, that is a definite sign they need to be replaced. The tip of the gear teeth should have a flattened surface, not a pointed one. The same thing can happen to the gear teeth on the upper and lower drive shafts. If the teeth wear away to a point, they can longer mesh with the coupling and your final drive will either be very weak or stop turning altogether. Another sign of trouble to look for is too much play in the lower gear bearing -- another sign that replacement is imminent.

An important thing to remember when replacing final drive gears is to never just replace one gear -- if one gear fails, the gear set is about to go, too. You'll save yourself considerable downtime by replacing the set.

Brake Assemblies

Brake assemblies can cause some serious problems with final drives and some parts may need to be replaced. The part that experiences the most wear is the brake disk pack, which is not difficult to replace. When it comes time to install the brake disc pack, make sure you use the specified height or, if you aren't sure that is, copy the order (and count) for the brake discs and spacers that you removed. Also be careful when installing the brake seal.

Surfaces and Lapping

Some damaged surfaces, like a distributor out of a final drive, can be restored to factory specifications through the proper use of a lapping table. Lapping uses special abrasives to achieve a certain level of flatness and surface finish. This level of precision is difficult to achieve without the right equipment and experience. However, other parts can be restored through hand lapping.

Issues with Hydraulic Lines

Another area where you might have to do some adjustments or repairs occasionally is the hydraulic lines. If you do have to replace hydraulic lines, keep these guidelines in mind:

- Avoid tight bends and curves

- Use a protective guard over lines that rub against the machine or that are exposed to high temperatures

- Fix leaks right away

Flushing The Hydraulic System

If there has been a catastrophic failure in your hydraulic system, you may need to flush your hydraulic fluid. This is more involved than just changing out your hydraulic fluid. Flushing your system means purging it of all old fluid, contaminants, and sludge. There are a couple of different ways to do this, including the double oil and filter change.

Reassembling the Final Drive

When it comes time to reassemble your final drive, you might want to consider using Loctite threadlocker to keep critical bolts in place.

Conclusion

Final drive repair sometimes takes the skills and experience of a professional, but not all tasks are that complicated. If you feel like a repair is too much for you to handle or you just don't have the time to deal with it, don't hesitate to contact a hydraulics expert.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.