If you have a Bobcat T180, Bobcat T190, or Bobcat T140 compact track loader, you may eventually need to replace the brake pack. In this Shop Talk Blog post, we are going to talk about what the brake pack is, how it works, signs of wear, and what to expect when it comes time to replace it ... complete with a video from Dr Drive himself!

Bobcat T190 Brake Pack

The Bobcat T190 brake assembly contains the brake pack. The brake pack consists of the large brake piston, a Belleville washer that pushes the brake piston down to lock the brake disc, and the brake discs and spacers (often referred to together as the brake discs, brake disc pack, or stack). These components interface with the upper drive shaft to achieve deceleration (aka: braking). When it comes time to fix a final drive, brake packs and brake assemblies often come into play.

Brake Disc Pack

One of the key components in the brake pack is the brake disk pack, or stack. The brake stack is a measured height. Shims may be used to achieve the correct height, such as 36.5 mm (+- .05 mm). Some of the brake discs have gear teeth along the outer diameter with the inner diameter smooth, while other discs have the gear teeth along the inner diameter with a smooth outer diameter. Shims have no gear teeth. In the image shown, you can see the shims on the left side and the brake discs themselves on the right.

One of the key components in the brake pack is the brake disk pack, or stack. The brake stack is a measured height. Shims may be used to achieve the correct height, such as 36.5 mm (+- .05 mm). Some of the brake discs have gear teeth along the outer diameter with the inner diameter smooth, while other discs have the gear teeth along the inner diameter with a smooth outer diameter. Shims have no gear teeth. In the image shown, you can see the shims on the left side and the brake discs themselves on the right.

The discs with gear teeth on the outside are often referred to as spacer plates. Their teeth mesh with the teeth on the inside of the brake housing. These discs can move up and down the length of the drive shaft but they cannot rotate at all. The brake discs, on the other hand, have teeth on the inside and mesh with the upper drive shaft. Because they mesh with the upper drive shaft, they also rotate with it. Like the spacer plates, they can move up and down the length of the drive shaft.

How the Braking System Works

When pressure drops, the large brake piston falls and is forced against the brake disc stack by the Belleville washer. The large brake piston compresses the brake discs and spacer plates together. Friction is generated as the plates and discs are forced together. The spacer plates mesh with the teeth inside the brake housing and cannot rotate. As they are pressed tightly against the brake discs, the brake discs can no longer turn with the upper drive shaft and the drive shaft is forced to come to a stop.

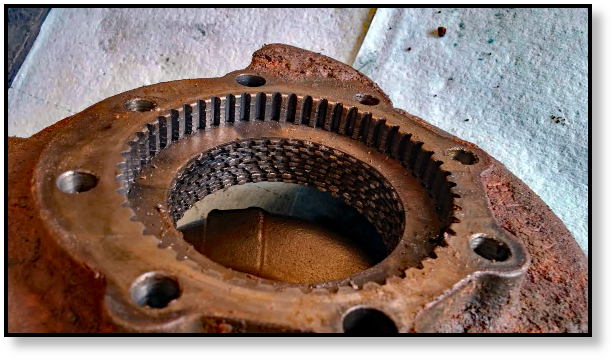

In the image above, you can see a damaged brake assembly taken from a final drive motor that came into the shop. If you look closely, you can see scarring on the teeth inside the brake housing. You can also see how the brake disc stack is arranged inside the brake housing.

Symptoms and Signs of Brake Problems

Brake problems can manifest in different ways with the most common being a final drive that refuses to turn or seems to be lacking power. Once you remove the brake pack from the final drive, you can usually tell rather quickly if it is the source of your problems. Extreme wear takes the form of scratches, discoloration from excessive heat, damaged teeth, and broken discs, as you can see in the accompanying image. You may also see scarring on the teeth inside the brake housing.

Brake problems can manifest in different ways with the most common being a final drive that refuses to turn or seems to be lacking power. Once you remove the brake pack from the final drive, you can usually tell rather quickly if it is the source of your problems. Extreme wear takes the form of scratches, discoloration from excessive heat, damaged teeth, and broken discs, as you can see in the accompanying image. You may also see scarring on the teeth inside the brake housing.

Note that low charge pressure can cause the brakes to not fully release, which can cause a loud squealing and loss of power.

Tips for Replacing the Brake Pack

Here are some hints, tips, and general guidelines for correctly replacing a brake pack on a final drive motor.

When you remove the cover from your Bobcat T190 final drive, the first thing you will encounter is the large brake piston and the Belleville washer. Once those are removed, you will encounter the upper drive shaft and the brake disc pack. The replacement process is rather simple. When it comes time to install the brake disc pack, make sure you use the specified height or, if you aren't sure that is, copy the order (and count) for the brake discs and spacers that you removed.

Remember to be careful with the brake seal and take the time to install it correctly. Note that if there are scratches or sharp edges on the large brake piston, they can tear the ID of the brake seal too. Scratches on the back (OD) of the seal or brake housing can result in leaks and a failure of the brakes to complete release (which leads to a whole new set of problems). Sharp edges on the brake piston knob can damage the brass bushing in the brake shaft and lead to the large brake piston sticking and as well as uneven application of the brakes.

Final Drives and Brake Assemblies

Like most other components, the brake assembly on a final drive will eventually require service. However, avoiding excessive braking and "riding the brake" will help your brakes to last at least their expected lifetime. If brake issues are not addressed, they can lead to damage to your final drive or hydraulic drive motor.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.