Final Drive Motor Failure

There are certain items on a final drive that are more likely to fail than others. They will cause damage to the motor, if left unchecked. Routine maintenance of these items will not only prevent damage but greatly extend the life of the components of the final drive motor.

Here are a few more blog posts that you might find helpful ...

- What's Wrong With My Final Drive Motor?

- 5 Signs Your Skid Steer Hydraulic Motors Need Service

- Troubleshooting Final Driver Problems -- Eliminating External Causes

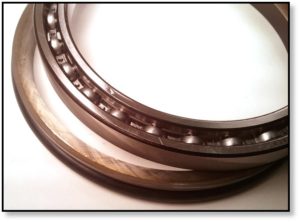

Main Bearings

Once one of the main bearings starts to fail, it can take the rest of the final drive with it. In fact, the main bearings are one of the most common components to fail on a final drive. You can tell it’s having problems when there is excessive noise or vibration, the outer seal is beginning to leak, or the gearbox is heating up too much. Note that when the main bearing is replaced, the face seals are typically replaced at the same time.

Save

Gears and Gear Bearings

Gears and Gear Bearings

Another source of problems can be with the gears themselves. One area of concern is the gear teeth. The tip of the teeth should have a somewhat flattened surface. However, as the gears begin to wear, the tip of the teeth will begin to away leaving the teeth with a pointed tip. When they have worn to this degree, it’s time to replace them. Another common issue related to the gears is too much play in the lower gear bearing.

Upper and Lower Shafts

The upper and lower shafts are where are few more issues can crop up: look for damaged gear splines and too much play. You’ll notice the gear splines on the new upper shaft shown below have a flat area on the top of the gear teeth.

If that flattened surface has been worn away until the teeth look pointed, it’s time to replace the shaft. In some more severe cases, such as the one shown below, the teeth have been worn away until the shafts can no longer engage the coupler. Again, when the teeth begin to show excessive wear the shaft really needs to be replaced.

Save

Save

Save

Gear Plate

The gear plate sits against the surface of the bearing, and with time the bearing can wear a significant groove in the plate. When that happens, it’s a good idea to replace the gear plate or use lapping to restore the flatness of the surface.

Seals

Whenever a final drive is being overhauled, it is best practice to go ahead and replace all seals and o-rings. These are, of course, another common source of problems in final drives and their wear is evidenced by leaks of either gear oil or hydraulic fluid.

Most Common Cause of Failure for a Final Drive

We've talked about the most common parts to fail on a final drive, but what about general causes of failure? Our expert told us that about 90% of the drives we repair are caused by a clogged case drain filter.

The second leading cause of final drive or travel motor failure is a weak charge pump. If the charge pump is weak, it will not be able to provide enough hydraulic pressure to release the internal brake, which essentially means driving with the emergency brake on. One of the tell-tale signs is a loud squealing noise and lack of machine movement. What's bad about a weak charge pump is that if you replace the damaged final drive with a new one without replacing the charge pump, it will damage the new final drive, too.

Save

Save

Conclusion: Preventing Component Damage

The most common failure areas in a travel drive or final drive are the main bearings, gears and gear bearings, upper and lower shafts, gear plates, and seals. If you find yourself needing to fix a final drive, one or more of these parts may need to be replaced. Routine maintenance -- including checking and replacing the case drain filter according to schedule -- can greatly extend the life of these components and prevent damage to them.

IN THE KNOW: For more valuable information on potential final drive problems you can avoid get the Texas Final Drive free eBook on Final Drive Motor Case Drain Disasters.

Save