Sometimes, what seems to be an issue with the final drive or travel motor actually has an external cause. Replacing the final drive will not fix the problem, though the problem may eventually damage the final drive. In this Shop Talk Blog post, we are going to discuss how to troubleshoot final drive problems to eliminate the possibility of external causes.

Is there a problem with the charge pump?

If you notice the final drive seem weak and is making an unusual screeching noise, the problem is most likely the charge pump. If the charge pump is weak, it cannot provide enough pressure to disengage the internal brake on the travel motor. The result is the equivalent of driving a car with the emergency brake on. While this problem is not in the final drive itself, failure to address it will eventually result in severe damage to the final drive motor.

Is the machine trapped in high speed mode?

If the machine keeps steering to one side or has issues trying to climb a steep grade, one of the final drives may be trapped in high-speed mode. High-speed mode means less torque. If your final drive is stuck in high-speed mode, it probably will not be able to generate enough torque to move the load. This would be a problem with the speed control system and not with the final drive.

Are the final drives/track motors receiving the correct hydraulic pressure and flow?

A lack of hydraulic pressure and flow is one of the most common causes behind a weak final drive or travel motor. This can be confirmed by checking the pressure on the final drive and referring to manufacturer guidelines to determine what the reading should be. If this is indeed the cause, then the problem is not your final drive; there could be insufficient fluid in the hydraulic tank, a hydraulic fluid leak, or a similar issue.

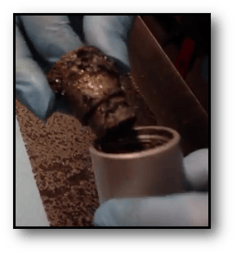

Is there back pressure, or a blockage in the motor case drain line?

The case drain line is a low pressure line, but it can become pressurized when there is a blockage in the line. If your final drive motor has a case drain line, trace the line until you find the case drain filter. Remove the case drain filter and check to see whether it is clogged or blocked. If in doubt, replace the filter and determine if there is improvement in the performance of your hydraulic motor. Always follow the manufacturer's recommendation for checking the case drain filters. You will save thousands of dollars in unnecessary repairs and avoid some truly catastrophic damage to your final drive motor.

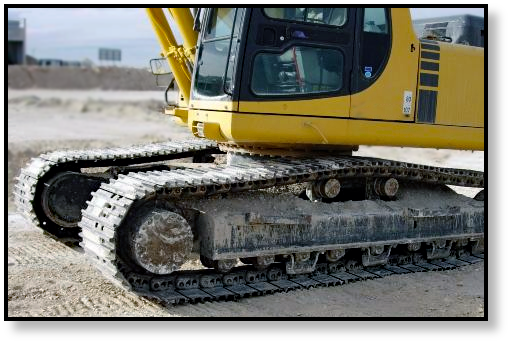

Are the tracks too tight?

If you have a CTL, MTL, or mini-excavator, the condition of the tracks can affect the performance of your final drive motor. If the tracks are too tight or if the tracks, idlers, and track rollers aren't in good condition, the increased friction can cause your final drive motor to seem weak. Check the tightness and condition of your tracks before you conclude that the problem is with the final drive.

A Word of Caution

Replacing a final drive without making sure that it is the problem will only mean more downtime and the potential for irreparable damage to the new final drive. If there is something wrong with your final drive, always address external causes before installing a new, reman, or rebuilt final drive motor. If you aren't sure whether it's the drive or not, describe the symptoms to an expert and get a second opinion.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.