Bearings provide support, aid in alignment, constrain motion, minimize the wear and tear experienced by other components, and reduce friction. They are an indispensable part of your final drive motor, and when they fail the results can be catastrophic and irreparable. In this blog post, we are going to review the basics of bearings in a final drive and discuss topics including maintenance, cleaning, inspection, and signs of failure.

Here are a few other blog posts you might find helpful:

Types of Bearings Used in Final Drives

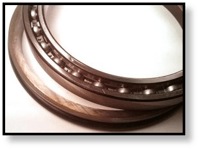

The main types of bearings used in final drives are plain bearings (also known as bushings), ball bearings, roller bearings, needle bearings, and tapered bearings. Except for plain bearings, these are all anti-friction bearings. Anti-friction bearings are known for their ability to reduce friction drastically.

Bearing Maintenance

Bearings must have sufficient and appropriate lubrication to function efficiently. Lubrication reduces friction, protects surfaces during metal-to-metal contact, and conducts heat away. Without lubrication, bearings will eventually begin to overheat, suffer surface wear, generated more contamination, and eventually seize up. The aftermath of these effects is not good.

Inside the hydraulic portion of your final drive, the bearings get their lubrication via the hydraulic fluid. On the planetary side, the bearings are dependent on the gear oil. Some final drives have a separate lubrication system set up for the main bearing that requires its own unique type of oil.

Gear oil and bearing oil need to be checked and changed according to manufacturer guidelines. You should never mix different types of oil because not all lubricants are compatible with each other. When changing out the oil, be sure to do so in as clean an environment as you can. If your final drive starts leaking oil, whether its gear oil or hydraulic oil, get that leak fixed as soon as possible. Leaks not only allow lubricant to exit the system but allow damaging contaminants to make their way into the system.

Signs of Bearing Failure

Another aspect of bearing maintenance is learning to recognize when a bearing has reached the end of its useful life. Bearings have a limited lifespan, and this makes sense when you recall that one of their purposes is to reduce the wear and tear on other components in the system. That means that your bearings are going to wear out, and you can minimize the damage from a worn out bearing by learning the signs of imminent bearing failure:

- Excessive heat

- Vibration

- Noises

If your final drive starts overheating (e.g., water sizzles when it comes into contact with it), begins vibrating, or starts making new sounds, then it’s time to send your final drive in for evaluation and possible bearing replacement.

Bearing Failure

The number one cause of bearing failure involves issues with lubricant. Insufficient lubrication, the wrong type of lubrication, and contamination all contribute to premature bearing failure. When lubricant gets things like metal flakes, abrasive particles, or water in it, it can no longer do a good job.

That’s why it is important to use clean, fresh lubricant and take care not to introduce dirt, dust, and moisture when checking/changing lubricant. That’s also why we emphasize the importance of not ignoring leaks because they allow contaminants to get access to your bearings. Premature bearing failure can be prevented with the right kind of maintenance.

Cleaning Bearings

If you’re concerned that your bearings may be wearing out, you might want to open up your final drive. To correctly inspect your bearings, it’s essential to clean them first so you can visually check the condition of the critical surfaces. Most experts recommend the use of petroleum solvents and lint-free rags for cleaning bearings. The bearings should be cleaned, then rinsed with clean solvent.

Drying Bearings

Once your bearings are clean, don’t spin them dry using compressed air. Spinning them can damage the surfaces of the bearing that come into contact with each other because there isn’t enough lubricant to protect them. What you want to do is hold the inner and outer races together so that it won’t turn and then use compressed air to dry it. Otherwise, you can ruin a perfectly good bearing.

Inspecting Bearings

Here’s what to look for when inspecting your final drive bearings:

- Dented seals

- Damaged or broken separators

- Cracks in the race

- Damaged or broken balls/rollers

- Flaking, scratched, or pitted races/balls/rollers

- Wear tracks on the outer race

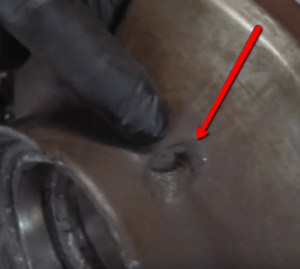

If you see any of these signs, it’s time to replace the bearing. Also, if the balls/rollers are no longer inside the bearing, that's another definite sign that it's time to replace the bearing -- the needle bearing you see in the picture above!

Conclusion

Don’t neglect your bearings -- when a bearing goes out, it can take out a bunch of other key components with it. The picture above is from a final drive that was sent in to us after it failed. What you see is the aftermath of a failed main bearing. If you think the bearings are about to go out on your final drive, don’t delay -- send it in for evaluation.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.