Any type of machine you encounter is going to have bearings in it. In this Shop Talk Blog post, we are going to discuss the types of bearings in your final drive hydraulic motor. We'll also look at the different functions they serve, signs of failure, the aftermath of failure, and how to prevent failure.

Review of Bearings

All bearings serve three basic purposes:

- Reduce friction

- Constrain motion to one direction

- Provide support

There are many different types of bearings: plain, ball bearings, roller bearings, jewel bearings, magnetic bearings, flexure bearings, and hydrodynamic bearings. However, there are only about three or four different kinds you’ll find inside your final drive.

Bushings

Bushings, also known as plain bearings and sometimes journal bearings, are the simplest of all bearing designs. They look like a cylinder and primary provide support and constrain motion. They are usually the cheapest of bearings, too.

Rolling Element Bearings

The other major category of bearings you'd find in a final drive would be rolling element bearings. The most common type of rolling element bearings are ball bearings, roller bearings, tapered roller bearings, and needle bearings. Rolling element bearings have much, much lower friction than bushings. Because of this, they are sometimes referred to as anti-friction bearings.

The other major category of bearings you'd find in a final drive would be rolling element bearings. The most common type of rolling element bearings are ball bearings, roller bearings, tapered roller bearings, and needle bearings. Rolling element bearings have much, much lower friction than bushings. Because of this, they are sometimes referred to as anti-friction bearings. Signs of Impending Bearing Failure

Bearings are eventually going to fail, but there are signs of impending bearing failure that you can watch (and listen) for. If your final drive starts making high-pitched noises and/or starts vibrating, that can be a sign that the bearings are about to fail. Another sign that the bearings are about to go it is overheating. If the final drive is too hot for you to put your hand on, or if water sizzles when it comes into contact with it, then there is a good chance you need to replace the bearings.

When Bearings Fail

When a bearing fails but the final drive keeps being used, the repercussions are going to be expensive. Your final drive will start to overheat because of increased friction. The other parts that depend on the bearing will start experiencing accelerated wear. Given enough time, they will experience irreparable damage.

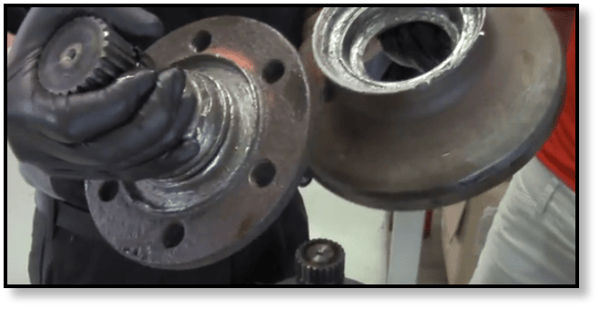

The bearings soon lose their ability to keep things in alignment (like gears and shafts). As things get more and more out of alignment, the damage and wear keep getting worse. You also end up with internally generated contamination in your final drive from the excessive wear that is going on. If you still keep running your final drive without replacing the failed bearings, you might end up with a chewed up final drive as seen below.

Bearing Life

Bearings, like most other parts, have a limited life. How long they last can usually predicted quite well by engineers. That expected life, however, is significantly affected by lubrication. Proper lubrication involves not just using the right lubricant and using lubrication that is clean. Contamination in the lubricant, whether that lubricant is hydraulic fluid or gear oil, will greatly reduce the useful life of a bearing. A lack of lubricant will undoubtedly lead to early failure.

Conclusion

Keep your final drive bearings lubricated by following the manufacturer’s instructions and schedule, not mixing different types of oil, and avoiding the introduction of contamination. When the bearings are showing signs that they are about to fail, get your final drive evaluated as soon as possible.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.