Why don't we see case drain filters on all compact hydraulic equipment? There are pros and cons to including them in the hydraulic design. If your machine requires one, then it is critical that you replace it regularly.

Here are some other Shop Talk Blog posts you may find useful:

- Troubleshooting a Final Drive Using Case Drain Flow

- Bobcat Final Drive Failures and Case Drain Filters

- Preventing Case Drain Related Failures

We’ve talked quite a bit about case drain filters, including why they're important and what happens when they aren’t changed out regularly. However, some in the hydraulics community don’t agree with using case drain filters. One of the most outspoken critics of case drain filters is Brendan Casey, author of The Catch-22 of Filtering Case Drain Lines article on Power & Motion. Another article on this subject was Hydraulic Pump and Motor Case Drains: Should You Filter? in Machinery Lubrication.

Why Case Drain Filters are Used

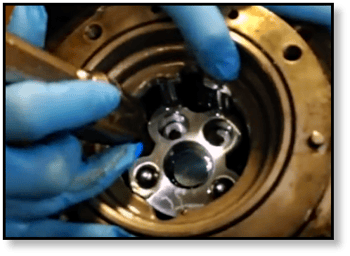

The reason why a case drain filter is placed between a hydraulic motor and a hydraulic reservoir is simple: to prevent cross-contamination from the hydraulic motor. First, keep in mind that hydraulic motors do generate their own contamination. As metal surfaces interact with each other, there will eventually be tiny flakes of metal that come loose with wear, chips that might come loose from a ball within an anti-friction bearing, or tiny slivers from splines. If not stopped, this generated contamination, not unlike what you can see in the picture below, will eventually make its way into the reservoir.

So it is true that case drain filters do an excellent job of preventing contamination from the final drive motor from continuing the system. So that isn't what engineers like Casey are arguing about.

Clogged Case Drain Filters

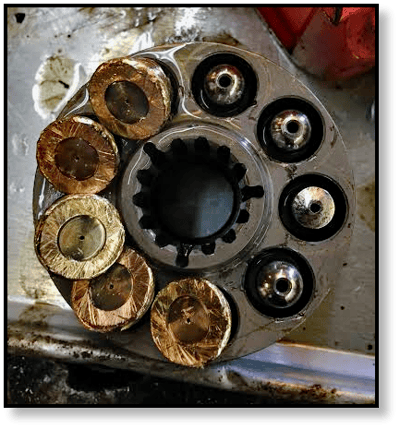

Casey points out that the problem with using a case drain filter is the excessive case pressure that results when it becomes clogged. This excessive pressure develops as the case drain filter becomes clogged, like the one shown below. Left unaddressed, that pressure will lead to a catastrophic failure of your final drive motor. Again, this is something that we’ve discussed several times in our Shop Talk blog and will review here.

Blown Seals

As the hydraulic pressure inside the final drive motor begins to increase, the shaft seal is going to be experiencing more internal pressure than it was designed to withstand. Casey points out that “ … the seal lip [will begin to] wear a groove in the shaft, eventually resulting in leakage past the seal.” When the seal between the hydraulic hub and the planetary hub starts leaking, the hydraulic fluid will mix with the gear fluid. This is bad for the gear hub, as hydraulic fluid doesn’t provide the lubrication requirements needed by the planetary gear system.

Mechanical Damage

What happens inside the hydraulic motor quickly reaches catastrophic damage levels. We’ve seen blown piston shoes, damaged retaining plates, shattered bearings, and other horrific results -- and these are things that require replacement, many of which are expensive. However, when the pressure from a clogged case drain filter has worked, buying a reman final drive is cheaper than replacing parts.

We mentioned piston shoes blown off the end of axial pistons, but remember that axial piston motors aren’t the only kind that can suffer the repercussions of a clogged case drain filter. In radial piston motors, the piston can actually be lifted on the cam and then driven back into it.

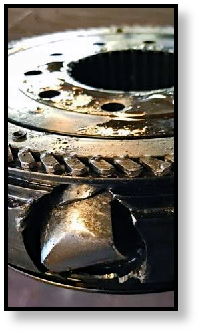

Cracked Cores and Missing Cover Plates

When the pressure builds up high enough, the result can be a cracked core, a cracked cover plate, or even a missing cover plate that can unexpectedly fly through the air and damage whatever it hits.

Conclusion

Some hydraulic engineers agree with Casey that using a case drain filter isn’t worth the potential damage that can be caused by neglecting it -- which is probably why you’ll see so many hydraulic systems without them. But, on the other hand, if your system was designed with one, as many Bobcat machines are, you need to change it every time you change your other hydraulic filters. The cost of a case drain filter and the effort that goes into replacing it is far cheaper than the damage that can result from neglect.