A good number of the failed Bobcat final drive motors we see come in are related to the case drain filter. Here's why -- and how to keep it from happening to you!

Here are a few other Shop Talk Blog posts you might be interested in:

- Just the Facts about Case Drain Filters

- Bobcat 325 Rotator Group Damage

- Autopsy: Bobcat 331 Mini-Excavator Final Drive

Case Drain Line

Many Bobcat machines -- including both their skid steer loaders, compact excavators, compact track loaders -- have a case drain line with a filter between the final drive motor and the hydraulic tank. It allows the internally leaked oil (which is a good thing) to be returned to the hydraulic tank under low pressure. To protect the rest of the hydraulic system from contaminants that might make their way into the final drive motors, manufacturers like Bobcat may put a filter on the case drain line.

Case Drain Filters

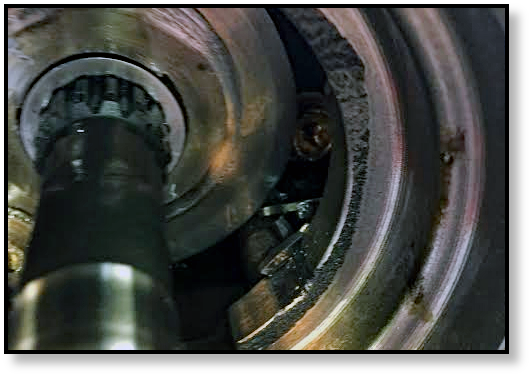

In the case of Bobcat, these case drain filters are contained in a relatively small aluminum cylinder that you can find between the case drain line and the hydraulic tank. Once you have opened the cylinder, you'll see the actual filter element. A brand new one has a gold or bronze color. If you case drain filter looks like the one below, you've waited way too long to change it out!

Clogged Case Drain Filter Failure Modes

If you wait to long to replace the case drain filters, then you will start having problems with your final drive. It basically works like a stack of dominoes: each issue just leads to another issue. It starts with a build up of pressure in the case drain line, which is supposed to be a low-pressure line. That pressure builds up because the excess hydraulic fluid has no where to go.

The buildup in pressure will begin to lead to failing seals ... including the seal that separates the hydraulic hub from the planetary gear hub. When that seal fails, the gear oil and hydraulic fluid begin to mix. Components may find themselves out being forced out of place (e.g., the piston shoes) and that leads to more devastating damage.

As the pressure continues to build, the cover plate of your final drive may crack or -- in a worst case scenario -- launch off your final drive motor and fly through the air. By the time the cover plate is cracked or missing, your final drive is totaled.

Preventing Case Drain Related Failure

There is a very simple, reliable way to prevent failure related to your case drain filter: replace the case drain filter at the same time you replace the other hydraulic filters on your machine. If you make it a habit to include the case drain filter in with the other hydraulic filters you change out, then the likelihood of issues related to the case drain filter are very small.

Conclusion

Don't let the final drives on your Bobcat machine end up totaled because of a clogged case drain filter. Change the filter regularly, and you can prevent this type of catastrophic failure. A filter that usually costs less than $20 can save you thousands of dollars in repairs and replacements.