Hydraulic contamination is a serious problem for final drive motors, and even more so for newer models that have tighter clearances. In this Shop Talk Blog post, we are going to discuss some of the results of hydraulic contamination and how to prevent them. It's easier than you may think!

Here are a few other Shop Talk Blog posts you might enjoy:

- 6 Types of Hydraulic Fluid Contamination

- Generated Contamination in Final Drive Motors

- Preventing Hydraulic Contamination

Critical Surface Damage

Abrasive particles, which can include everything from sand particles to slivers of metal, can cause damage to critical surfaces. Scratches and abrasion may not seem like a big deal, but they can compromise the performance of your final drive motor. Scratches and abrasions can cause unnecessary losses in your final drive that cause it to be far less efficient. In addition, this type of surface damage can lead to even more abrasive particles in your system.

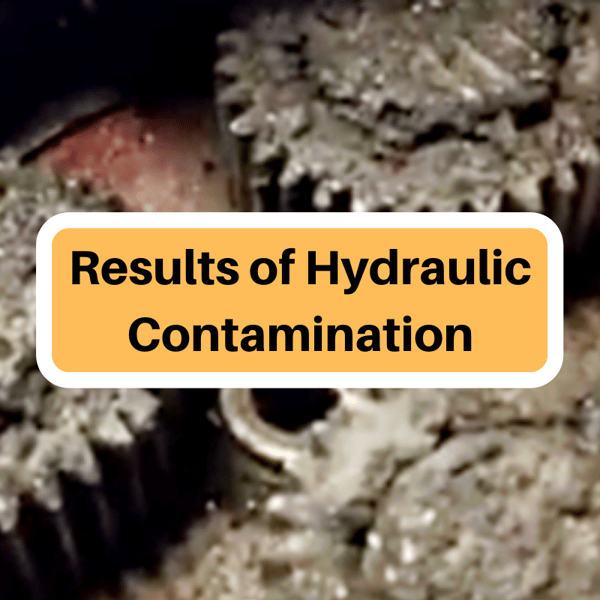

This image shows a fairly extreme example of contamination that was allowed to go on too long, which meant that even more slivers of metal built up in the system and compounded the damage. When damage reaches this point, the final drive simply isn't salvageable.

This image shows a cam ring that has some damage to the interior surface. This could be the result of normal wear and tear, but this type of damage will be worse when abrasive materials make their way into the hydraulic fluid.

What you see here is a worn out O-ring ... when o-rings and seals fail, they can contaminant the hydraulic system and allow other contaminants to make their way inside your final drive motor. That's part of the reason why we always replace the seals and o-rings when we work on a final drive.

Blockages and Restricted Flow

In final drive motors that have extremely tight tolerances and small clearances, some forms of contamination can actually build up and begin to cause blockages. This can be see in other areas of hydraulic machines, including valves. Very small diameter contaminants that we may mistakenly assume are too small to cause problems are actually small enough to become trapped. However, larger particles can also lead to problems with blockages and or restricted flow.

Ruined Gear Oil

Hydraulic fluid isn't the only area where a final drive motor can suffer contamination. The image below shows what can happen when leaking seals allow dirt and sand to make their way into the planetary hub on a final drive motor. What you see here is gear oil that has basically been turned into an abrasive sludge. This type of sludge no longer protects surfaces and reduces friction but actually does the opposite.

While you may be able to clean up these parts, they have probably experienced some destructive surface damage. In all likelihood, the bearings will need to be replaced.

Preventing Damage

As you can see, contamination in your final drive is a big deal and can lead to expensive repairs. When you suspect a seal has begun to fail, then it needs to be replaced ASAP so it can continue to protect the inside of your final drive from everything outside.

Ideally you should filter your hydraulic fluid before it goes into your machine, but we understand that for small operations that may not be feasible. However, you can keep your hydraulic fluid sealed when not in use and avoid opening up your final drive in areas with dirt and grime.