Your final drive is just one of many components that make up the hydraulic system on your machine. All those components share the same hydraulic fluid. If contamination enters at one point in the system, you run the risk of it causing damage to other parts of the system. That’s why it is so critical to you do your best to prevent hydraulic contamination. In an ideal world, you would only open up the hydraulic system in a clean environment -- but we realize that isn’t always realistic. Here are some practical hints and tips to help you prevent hydraulic contamination.

Here are some other blog posts on similar subjects ...

- Hydraulic Contamination Issues in Newer Machines

- Types of Hydraulic Contamination that Affects Final Drives

- Generated Contamination and Final Drive Motors

Clean Up the Machine

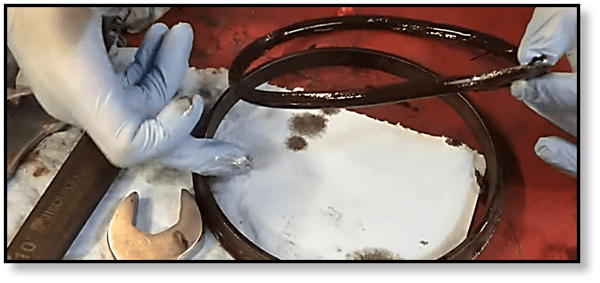

Clean the machine or component around where you will be opening it up. You don’t want dirt, sand, dust, and grit falling into the system when you open it up. If there’s a lot of debris packed around the opening, it will be worth your time to loosen it up and either brush it out or wash it out. That’s why we thoroughly clean final drives before we open them up -- to prevent crud from falling inside when we do open them.

Realize the Limitations of Hydraulic Filters...

While hydraulic filters can usually keep the contamination more or less localized, that contamination can do expensive damage -- especially if it is localized to pumps or motors. Another fact to keep in mind is that filters can’t filter out everything.

...But Check and Replace Them!

Check your hydraulic filters according to manufacturer recommendations (including case drain filters). If they are clogged, then replace them. Also, avoid using cheap filters -- a cheap filter can do more damage than no filter at all. And, again, don't forget those case drain filters -- a clogged case drain filter can total a final drive.

Keep Your Tools Clean

Keep your tools reasonably clean, and remember that grease and rust flakes are considered just as damaging to a hydraulic system. Don’t throw a wrench in the dirt and then immediately use it on your hydraulic system.

Don’t Ignore Leaks

Don’t ignore leaks. Leaks let hydraulic fluid out and contaminants inside. If a seal is leaking or looks like it’s seen better days, that means you need to replace it. Check hoses for signs of leaks or cracks. If a hose shows such evidence, replace it. The same things that allow fluid to leak out will also allow other stuff to get inside.

Be Careful with Hoses and Connectors

Never let hoses and connectors lie in the dirt or on the ground. They will pick up dust and debris that can make its way into your system. Also, plug up the ends for the same reason.

Don’t Reuse or Mix Hydraulic Fluid

Never try to reuse hydraulic fluid. Never mix different types of hydraulic fluid, either. Ideally, all new hydraulic fluid should be run through a filter (or filter cart) before it is inserted. Even brand new hydraulic fluid can be contaminated.

Avoid Leaving Hydraulic System Open

Don’t leave your hydraulic system open unnecessarily. Plug the hoses and cap the openings as soon as you can.

Don’t leave components like motors, valves, and pumps open to the air unnecessarily, either. Otherwise, you run the risk of contamination by dust and moisture in the air. For the same reasons, don’t leave your hydraulic fluid in an open container for extended periods of time, either.

Conclusion

Hydraulic machines work in an environment filled with potential contaminants that can wipe out your system and bring your machine to a literal grinding halt. Newer machines are even more sensitive to contamination. However, a few common-sense precautions can significantly reduce your chances of having a machine fail because of hydraulic contamination.

We have a few more blog posts related to this subject that you should check out ...

- Hydraulic Contamination Issues in Newer Machines

- Hydraulic Drive Motors and Contamination

- How to Flush Your Hydraulic System

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.