Most experts agree that contamination is the number one cause of failure in hydraulic systems and components. This includes final drive motors and we see many final drives that have failed because of hydraulic contamination issues. In this Shop Talk Blog post we are going to discuss the different types of hydraulic contamination and the impact they can have on your final drive motor.

Particulate Contamination in Hydraulic Fluid

Particulate contamination in hydraulic fluid can take many different forms: dust, dirt, sand, grit, silica, fibers, flakes of rust, slivers or particles of metal, bits of degraded elastomeric seal, and any other small pieces of material that doesn’t belong in your hydraulic fluid.

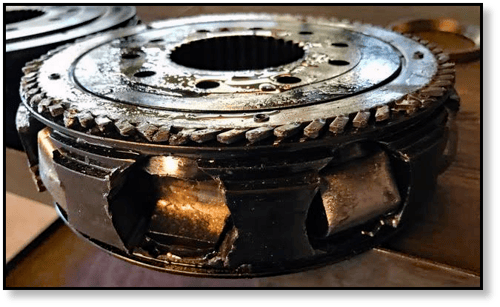

These particles do major damage when they find themselves in the clearances inside your final drive motor. And they are rough and irregular in shape, ready to tear into metal parts wherever there is metal-to-metal contact, like the damage you can see on the inside surface of the cam ring shown.

Particulate contamination can cause a host of problems, but most of those problems start with accelerated wear. Let’s say you have a piece of dirt that gets inside your system, barely big enough to be seen with the naked eye. That would be a particle with a diameter less than 40 microns across (particles that do the most damage fall into the 14 micron range,which is even smaller). We’ll assume you have an older model final drive with a clearance of about 40 microns between the piston and the bore.

That 40 micron particle ends up between the piston and the bore, and ends up abrading the surfaces it is in contact with. That causes even more particles as those tiny pieces of metal have to go somewhere. These particles are even smaller and can do even more damage. Over time, the bore begins to experience abnormal wear, which means more leakage inside your final drive. More leakage means less efficiency, so your final drive doesn't perform as well as it used to. The more wear that occurs, the more particles that are generated, creating a devastating domino like effect.

We have seen many final drive motors that were practically destroyed by contamination. The piston block from a Gerotor shown below is an excellent example. All of the horrific damage shown was traced back to contamination that went unchecked.

Non-Particulate Contamination in Hydraulic Fluid

Foreign particles aren’t the only type of contamination that you can find in hydraulic fluid. There is also non-particulate, or chemical, contamination. This includes water, air, and chemicals in trapped in your hydraulic fluid.

While water may be a fluid, it’s not the kind of fluid you want in your hydraulic system. If your fluid has a milky appearance, that will likely be due to the presence of water -- the most common contaminant in hydraulic fluid. Water is bad for your final drive motor for these reasons:

- It impairs the ability of the fluid to act as a lubricant

- It can hinder corrosion and rust protection

- It can lead to cavitation

- It can promote the development of sludge

If your hydraulic fluid looks foamy, then it is most likely been contaminated with air. Air is much more elastic than hydraulic fluid, which means your machine won’t perform the same when there is air in the hydraulic system. You won't be getting the same power and torque from your final drives. And, like water, the presence of air can lead to damaging cavitation. Cavitation is usually accompanied by a loud knocking sound and can cause components in your final drive to end up with a pitted surface.

If your hydraulic fluid looks foamy, then it is most likely been contaminated with air. Air is much more elastic than hydraulic fluid, which means your machine won’t perform the same when there is air in the hydraulic system. You won't be getting the same power and torque from your final drives. And, like water, the presence of air can lead to damaging cavitation. Cavitation is usually accompanied by a loud knocking sound and can cause components in your final drive to end up with a pitted surface.

Another form of non-particulate contamination is degraded hydraulic fluid. As hydraulic fluid ages or as it is exposed to elevated temperatures, many of the additives that make it especially effective begin to decompose and form new chemicals. This will affect the performance of your hydraulic system and is considered a type of contamination.

Conclusion

Hydraulic contamination is the number one cause of hydraulic system failure, and hydraulic motors are just as susceptible as pumps. Practicing fluid cleanliness, changing filters regularly, and fixing leaks quickly can help minimize the damaging effects of contamination.

Here are a few more posts on the subject of contamination that you might be interested in ....

- Hydraulic Contamination Issues in Newer Machines

- Hydraulic Drive Motors and Contamination

- Types of Hydraulic Contamination that Affects Final Drives

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.

Want to learn more about the reman process we use of final drive motors here at Texas Final Drive? Check out our fascinating video eBook below!