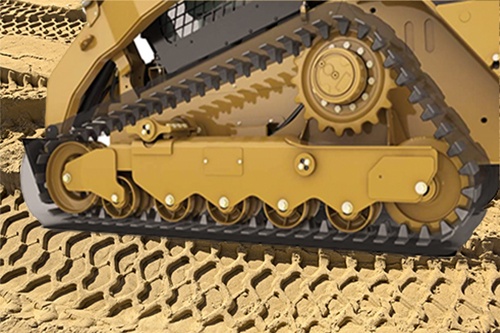

Track Drives Vital to CTL and MTL Equipment

If you own a CTL (Compact Track Loader) or MTL (Multi-Terrain Loader), you know that it needs a working track drive in order to move. Track drives are a vital part of your CTL, whether it's an ASV compact track loader or a CAT multi-terrain loader, they are also commonly neglected. In this Shop Talk Blog post, we are going to talk about three common mistakes equipment owners make in maintaining their track drive motors.