Learn how we diagnose a weak final drive motor.

Here are a few other Shop Talk Blog posts you might be interested in:

Past Shop Talk Blog posts have dealt with the external causes of a weak drive motor, which include

- A weak charge pump: If the charge pump is weak, it can't provide the pressure needed to disengage the internal brake

- Drive stuck in high-speed mode: high-speed mode means higher speed but lower torque

- A blocked case drain filter: this is very dangerous and can quickly destroy your final drive

- Track issues: if the tracks are too tight or the tracks, idlers, and track rollers aren't in good condition, the increased friction can cause your final drive motor to seem weak

- Incoming flow rates and pressures are too low: this could be to a leaking seal or not enough hydraulic fluid in your system, for example

The problem isn’t in your final drive if any of these issues are present. But, unfortunately, if you replace it, you’ll still have the same problem -- and we work hard to help our customers avoid this happening. That's why we encourage our customers to ensure that none of the issues are present.

Once all the external causes have been eliminated, it's time for us to look at your final drive and figure out the root cause of your problem. And that starts with looking at the case drain flow.

Case Drain Flow

Once we receive a weak final drive motor, our first order of business is to check the case drain flow rate leaving the final drive. The case drain line is responsible for returning the internal leakage from the hydraulic motor back to the tank. Remember that some leakage is good -- usually on the order of 2 to 10% of flow entering the hydraulic motor -- because it is used to lubricate motor components, carry away excess heat, and remove debris from the hydraulic motor. However, case drain leakage will increase as the components within the drive motor start to wear out.

The case drain should experience minimal flow at low pressure, and the exact amount can easily be checked against manufacturer specifications. However, if we discover that the flow rate is too high -- which occurs with weak final drives -- the next area to check would be the pressure relief valves in the valve block.

Pressure Relief Valves

A malfunctioning pressure relief valve results in too much pressure and too much flow, which will cause the final drive motor to seem weak. If pressure relief valves are stuck and not functioning correctly, the two leading causes are trapped debris (a contamination problem) or a broken spring (the most common issue). Replacing the valve should fix the problem.

Rotator Group

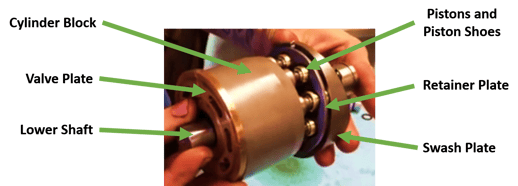

If the pressure relief valves check out, then the problem is going to be mechanical wear. Wear and tear is a natural result of use, but it's made worse when the hydraulic fluid is contaminated. We start by looking at the valve plate. Its purpose is to distribute fluid. Excessive wear will reduce the amount of work the hydraulic fluid can do.

If the valve plate is in good condition, the rest rotating group is next. Here we look for uneven wear and cracks. The image below shows a crack developing on the cylinder block -- which isn't a good sign. That crack is only going to get bigger, and will probably lead to broke pieces of metal coming off and causing irreparable damage inside the final drive.

We also take a close look at the piston shoes, checking for wear and excessive play. Here's an example from a radial-piston final drive motor, with a brand new example shown in the middle. This level of wear not only affects the performance of your final drive motor, but leads to slivers of metal that will damage the inside of your final drive.

Conclusion

Here at Texas Final Drive, we take a weak final drive motor very seriously. We don't want you to replace one that is in good condition, which is why we encourage you to eliminate any external causes before you send your drive motor in or order a replacement. If you have any questions, you can call us or email us.