When we hear the word “leak” or “leakage” in reference to a final drive motor, our knee-jerk reaction is to assume it's something bad. In a hydraulic system, though, internal leakage is good -- up to a certain point.

Here are some other blog posts you might find interesting:

- Rebuilding a Track Drive

- 4 Quick Tips for Extending the Life of Your Final Drives

- Hydraulic Pump Failure

We know it’s bad when we see hydraulic fluid leaking out of a final drive motor, but that’s not the only kind of leakage it can experience.

What is Internal Leakage?

Internal leakage is closely related to the operating clearances in hydraulic components. Let’s start by looking at final drive motors.

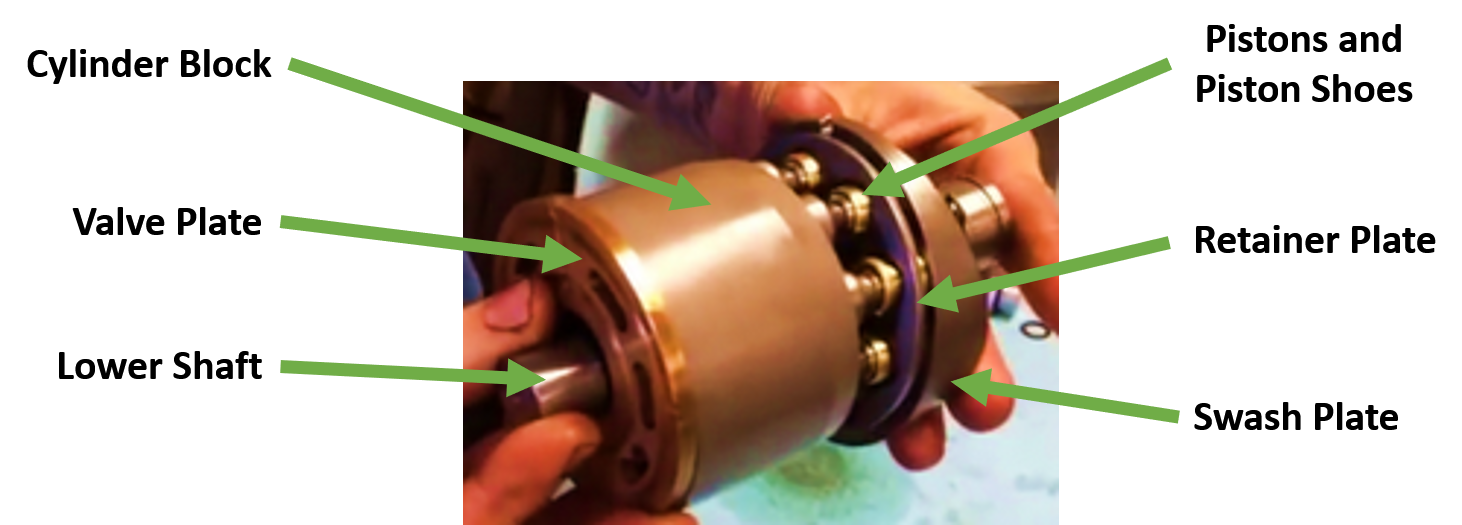

Your final drive motors are built with operating clearances. As an example, think of an axial piston motor and the clearance that exists between the piston and the cylinder block, shown below. This clearance is necessary to allow hydraulic fluid to provide lubrication between the piston cylinder and the opening for it. There is a certain amount of internal leakage that has to take place for operation.

Now, this leakage never leaves the system. It will always be returned to the hydraulic reservoir, often via a low-pressure drain line. Internal leakage does not contribute to the work being done by the final drive motor, though.

Good vs Bad Leaks

There can be other reasons for internal leakage to be designed in, such as cooling or cleaning. Regardless of the purpose, the fluid involved never leaves the system and always travels from an area of high pressure to an area of low pressure.

However (isn’t there always a however?), over time the operating clearance will grow in size, either through natural wear or wear resulting from particulate contamination in the hydraulic fluid. As the clearance grows, more fluid will be lost to internal leakage. And remember that internal leakage doesn’t do any work.

As more and more fluid is lost to internal leakage, the performance of your hydraulic system will begin to suffer. The efficiency of your system is going to be reduced. And if the operating clearances get large enough, the fluid may bypass its usual path, and your pump or final drive motor won’t accomplish anything at all.

Causes of Excessive Internal Leakage

Wear isn’t the only reason why internal leakage can occur. Using the wrong replacement parts or a shoddy rebuild can also make internal leakage worse. Wear can be accelerated by contaminated hydraulic fluid, using the wrong viscosity hydraulic fluid, or high operating temperatures.

Effects of Excessive Internal Leakage

When a final drive is being affected by excessive internal leakage, it will probably start acting weak. If it's just one motor, your machine may start pulling to the side. If it's both motors, you may find it harder to move up a hill or have trouble moving when you’re machine is loaded down.

Conclusion

Eventually, the components in your final drive motor are going to wear out and lead to excessive internal leakage if nothing else goes wrong. When that happens, there is a high probability that other parts of your final drive motor are wearing out as well. That isn’t always the case, and in some instances, it’s possible to rebuild the surfaces that have worn out and restore them to OEM tolerances and surface finish.

At Texas Final Drive, you can count on us to help you find the most economical and reliable solution to your final drive motor problems. We perform high quality rebuilds and repairs, while also carrying a massive inventory of new and reman final drives for sale. Contact us today to learn more or fill out a Request for Quote.

I