We see quite a few final drive hydraulic motors that have been severely damaged by abrasive contamination on the hydraulic side. In this Shop Talk Blog post, we discuss what abrasive contamination is, where it comes from, what it does to your final drive, and how it can be minimized.

Here are a few more blog posts you might be interested in reading ...

- 6 Types of Hydraulic Fluid Contamination

- Hydraulic Contamination Issues in Newer Machines

- Hydraulic Drive Motors and Contamination

What is Abrasive Contamination?

Abrasive contamination refers to particles 1) don’t belong in your hydraulic fluid and 2) can damage metal surfaces, including those inside your final drive. Think about it: a grain of sand by itself isn’t going to do too much damage to a metal surface, but if it forced against that surface with substantial force then it can cause some serious issues. Abrasive contamination can include materials such as sand, grit, concrete dust, dirt, and grit.

Sources of Abrasive Hydraulic Contamination

Some abrasive contamination enters the hydraulic system at the seals along the cylinders on the lifting arms of many machines. Leaky seals are another way that abrasive particles can invade your system -- if a seal can let fluid out, then that same seal can let dirt and sand inside. These particles can also get into your system when you open it up. It might be to check fluid levels, replace a final drive motor, detach a hose, or something similar.

Effects of Abrasive Hydraulic Contamination

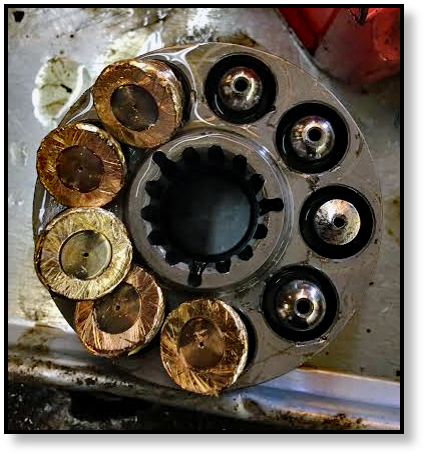

Abrasive particles, over time, will begin to wear away at the surfaces they encounter. One of the immediate effects of this is the generation of more contamination, using in the form of tiny metal particles. Another type of damage that results from abrasive contaminants is the wearing away of critical clearances that eventually result in compromised performance. We see this in many of the rotator groups we work with.

There are some surfaces in your final drive that need to be as smooth as possible, too. If they are damaged by scratches, gouges, and uneven wearing, they might be able to be restored -- such as distributors, which can often be restored by using a lapping table. But not all surfaces can be refinished, and a good example of that would be some of the interior surfaces of a cam lobe ring.

If enough particulate contamination gets into your hydraulic system, it can begin to clog up your filters. A excellent example of the dangers associated with that would clogged case drain filters. Once they clog, the case drain line can no longer drain away excess hydraulic. Pressure builds up, seals fail, and the final drive can quickly end up totaled.

Preventing Contamination

The first key to preventing hydraulic contamination is practicing cleanliness. Before opening up a hydraulic port, always clean off the surrounding area first. If you don’t, dirt, sand, and grit can fall into that port and gain access to the system or whatever component is involved.

When you remove a hydraulic hose, clean the area around the connection first. Plug the ends of the hoses with something and put them on a clean surface. Before you disassemble a final drive, clean off as much of the exterior debris as you can. Remember that laying down some cardboard or plywood is a quick way to make a clean surface for working on your final drive, even if you are forced to work on it in the field.

Also, only add clean hydraulic fluid to your system. Don’t leave your hydraulic fluid storage container open for extended periods of time, and don’t leave your hydraulic ports open unnecessarily, either.

Conclusion

Getting abrasive particles in your hydraulic system, and especially in your final drive motor, can compromise performance and cause severe damage that may not be repairable. However, by practicing cleanliness when maintaining your equipment, you can avoid many of these problems.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.