It’s never good when a final drive motor stalls or gets jammed, especially on the job site. But here’s an outline of typical causes and how we diagnose them.

Here are a few Shop Talk Blog posts you might find interesting:

- Revisiting the Topic of Gear Oil

- Load Sensing Final Drive Motors

- Gear Oil Part 1: How to Troubleshoot Gear Oil Problems with Your Final Drives

Three main things can lead to a jammed or stalled final drive motor: wear, lubrication issues, or problems with the rotator group on the hydraulic side. Here's how you can figure out which one is the problem.

Wear

Every mechanical system and component will experience normal wear that will eventually lead to failure -- and that’s true of final drives, too. Bearings, gears, shafts, and seals all have a limited life. So replacing parts as they wear out is critical to avoid cascade damage to other parts.

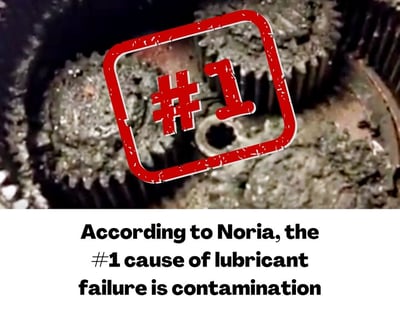

Normal mechanical wear can be accelerated by overloading the system, not providing enough lubrication, and allowing a component to fail without replacing it. Needless to say, this results in a final drive planetary hub that wears out much faster than it should. Wear can also be accelerated by overheating and particulate contamination, as shown below.

One of the insidious aspects of mechanical wear is that it can quickly turn into a cycle that will total your planetary drive. For example, it might start with metal flakes coming off one of the bearings. That metal flake will float around in the lubrication. During use, it can quickly be forced between two contacting gear teeth or between bearing surfaces. There it can cause another particle to break off. And the more metal particles and slivers there are, the faster metal contamination is generated. So eventually, the planetary gear set will be totaled.

Lubrication Issues

Without enough lubrication, your planetary will experience accelerated wear made worse by generated contamination. A leaking seal can cause it, so checking your gear oil regularly is important. And if you find yourself repeatedly having to top off your gear oil level. In that case, the problem is a leaking seal that needs to be taken care of immediately. Too little gear oil results in wear, just like we discussed earlier.

Another issue with gear oil that can lead to a stalled final drive motor is old, contaminated gear oil. As gear oil ages, some of the additives we depend on for its performance will begin to break down chemically -- which is why you should change it per manufacturer recommendations or you might end up with a mess like this.

Remember: a leaking seal not only means that gear oil can leak out, but abrasive contamination from the work site can make its way in and lead to serious damage.

Diagnosing a Stalled Final Drive

So, how do our techs deal with a final drive that comes to our shop stalled or jammed? Here’s our approach:

- Check gear oil for signs of contamination

- Check planetary gears for damage

- Check rotating assembly

Check Gear Oil

Start with the gear oil on the planetary side. First, get a container big enough to catch the gear oil and allow you to visually check it for metal particles as it drains out. Metal particles -- flakes, slivers, chunks, particles -- are the natural result of wear. Also, some drain plugs are magnetic, so we suggest looking at them to see if any metal flakes or particles are stuck to them. Shown below is an example of old gear oil that is likely doing more harm than good.

If you see metal flakes, slivers, or chunks on the plugs or in the gear oil, that’s a sign of wear to the point that the surfaces of gears, splines, and bearings are breaking off. And as they break off, they generate even more damage in an unforgiving cycle. By the time you’ve got enough slivers, chunks, and particles to see in your gear oil, you’ve got severe damage that will likely require rebuilding the planetary.

If the gear oil coming out is clean and clear, you need to check for issues within the planetary hub. And that leads to the next step.

Check Planetary Gears

First, remove the cover plate (and we know that can be easier said than done). Once the cover plate is off, inspect the gears for cracks and splines that could cause the drive to jam. Also, check the bearings. If you see no damage in the gear side, but the drive still will not move, the problem will be on the hydraulic side. The most likely issue is a problem with the rotating assembly.

Check Rotating Assembly

Next, we open up the hydraulic side to check the rotating assembly (also referred to as the rotator group). There, we look for anything that prevents it from transmitting motion. For example, the image below shows severe enough damage to jam the final drive motor.

Here's an example of bearing failure in the rotator group -- the technician's finger is pointing at shattered bearing components.

And in a radial piston motor, this can certainly bring a final drive motor to a stop.

Conclusion

This is a rough outline of troubleshooting a stalled or jammed drive motor or track drive. We'll gladly help you over the phone or via email if you have any questions.