Some models of two-speed final drive motors are load sensing. This means that the operator doesn’t have to change speeds -- the final drive detects when there is enough of a load to slow down. In this Shop Talk Blog post, we are going to talk about load sensing final drive motors, discuss how they work, and then examine the benefits they offer.

Here are a few additional Shot Talk Blog posts that you might find interesting:

- 3 Vital Questions about Single Speed and Dual Speed Final Drive Motors

- Is Your Final Drive Weak or Stuck in High Speed Mode?

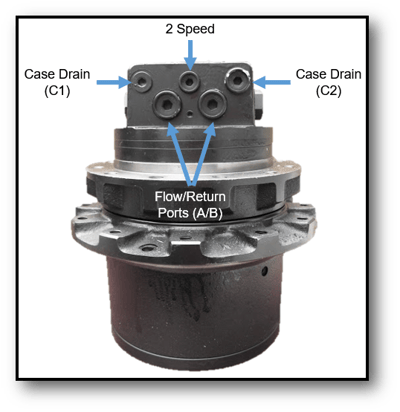

- Identifying the Hydraulic Ports on a Final Drive

Load Sensing

David Saunders at Crossco described this quite well in his post:

“When someone says a system is ‘load sensing,’ it means that it has been designed to operate at as low a flow and/or pressure as possible when no functions are actuated and is able to immediately ‘jump’ back up to the flows and pressures necessary to do the work demanded.”

When a hydraulic motor is “loaded” that means it is doing work -- meeting resistance as it turns. When significant resistance is sensed, the torque needs to go up which means the speed needs to go down. When minimal resistance is sensed, then the speed can go up and torque can go down. Keep in mind that low speed isn’t just for generating torque and carrying loads, however. Low speed is a big help when you have to be careful with positioning your machine (e.g., moving around in tight spots).

Multiple Speed Final Drives

Multiple speed final drive motors are always going to be variable displacement hydraulic motors. One of the most common types of load sensing final drive motors is an axial piston motor with an adjustable swash plate. An adjustable swash plate is what facilitates the variable displacement.

As the angle of the swash plate is adjusted, the volume of the hydraulic motor changes. If the displacement volume is reduced, the speed increases and the torque reduces. If the displacement volume is increased, the speed decreases and the torque increases.

Knowing when to adjust the swash plate is accomplished via load sensing control. The control decides when to adjusts the angle of the swash plate (in an axial piston hydraulic motor) to change the flow within the motor.

Benefits of Load Sensing

Load sensing is more than merely a convenience for operators. It can reduce fuel costs through more efficient use of the machine. In can also increase productivity because the machine will move at a faster speed when it is not loaded down. In addition, less heat is generated, and component life is also increased -- and that means lower maintenance and repair costs.

Conclusion

Whether you have a load sensing multi-speed final drive or a basic single speed, our technicians at Texas Final Drive can help you troubleshoot what's going on and, if necessary, assist you in tracking down a replacement at reasonable cost.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.