Hydraulic lines are a major part of any hydraulic system; the hydraulics on construction equipment such as skid steers, compact track loaders, and excavators are no exception. Since hydraulics are so vital to your equipment, we wanted to dedicate a Shop Talk Blog post to this subject. Whether you are maintaining your own equipment or restoring an older machine, here are five things you want to avoid doing with your hydraulic lines.

In this Shop Talk Blog post, we are going to look at 7 of the world’s largest excavators and consider them by the numbers. We’ve included several charts so you can get a quick idea of how they compare in terms of weight, bucket capacity, gross horsepower, track length, and more. Have any of you guys ever worked with one of these monsters? Tell us in the comments!

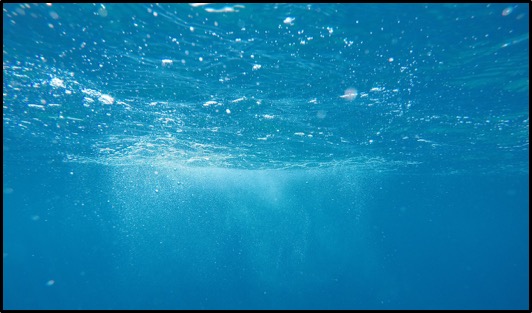

There are two approaches to excavating underwater. The first is through the use of amphibious excavators which work primarily in swamps, marshlands, and relatively shallow water. This blog post focuses on the second approach: excavators used in deeper waters which are partially (or totally) submerged.

Built Robotics has introduced an autonomous (self-driving) track loader that promises to disrupt the construction equipment industry. In this Shop Talk Blog post, we share some of the questions and answers that we had about this technology, such as what its capabilities are and how it works.

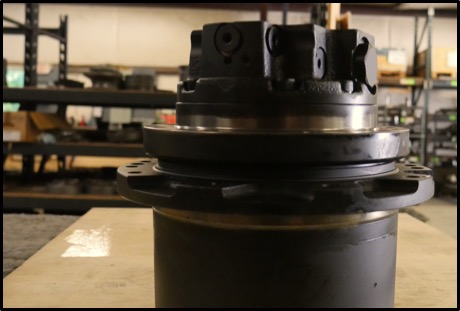

Reman/rebuilt final drives are an excellent option when your final drive or hydraulic motor refuses to work any longer. In this Shop Talk Blog post, we are going to present four reasons why you should consider a reman final drive the next time you need a replacement: price, performance, availability, and warranty.

Worst Advice We've Ever Heard about Gear Oil

Final Drive, Final Drive Maintenance, Gear oil, Maintenance

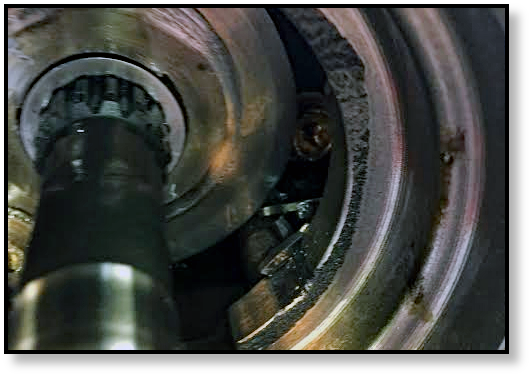

|Here at Texas Final Drive, our technicians have rebuilt and repaired thousands of final drives. Through the years, we’ve seen first hand the results of equipment owners following bad advice when it comes to gear oil. Here are three examples of the worst advice we’ve heard about gear oil and final drive hydraulic motors.

5 Common Hydraulic Motor Questions Answered

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Motors, Final drives, Final Drive Maintenance

|In this Shop Talk Blog post, we are going to discuss the answers to five very common questions about hydraulic motors: what is a case drain, how do hydraulic motors fail, what exactly is displacement, how are hydraulic motors rated, and how does a hydraulic motor differ from a final drive?

Final Drive Maintenance with Dr. Drive!

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Final drive motor, Maintenance, Preventative Maintenance

|

Maintenance is never a popular subject - especially when you have deadlines looming over your head. But you NEED to do your maintenance! In this Shop Talk Blog post, we'd like to help you keep a healthy perspective on the subject of maintaining your final drives, track motors, and hydraulic motors by discussing two major maintenance steps you should never, ever neglect.

5 Bulldozer Questions Answered

Heavy Equipment, Dozer, Crawler Loader, Bulldozer, Crawler Tractor

|Bulldozers, also known as dozers, crawler tractors, or crawler loaders, are found on just about every mining and construction site worldwide. In this Shop Talk Blog post, our goal is to discuss answers to common questions regarding our beloved bulldozer, including the origins of the bulldozer, how they are used, how they work, and what the biggest production bulldozer looks like.