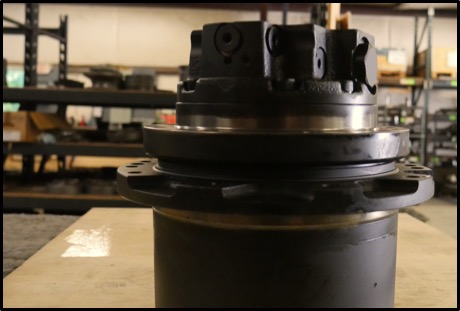

The Bobcat T190 is a compact track loader (CTL) that is no longer in production by Bobcat. However, it is still in use all across the United States. Even though the last production year for the Bobcat T190 was 2008, these machines have proven so sturdy and powerful that there is still a strong demand for used models and replacement parts. Here at Texas Final Drive, one of our most popular products is the reman/rebuilt Bobcat T190 final drive motor.

Reman Bobcat T190 Final Drives

Troubleshooting Final Drive Problems - Eliminating External Causes

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance

|Maintaining the Final Drive on Your Excavator

Final Drive, Final Drive Motor Seals, Final Drive Motors, Final Drive Maintenance, Excavators, Mini-excavators, Compact Excavators

|How to Get an Accurate Final Drive Diagnosis

Final Drive, Final Drive Failure, Travel Motor, Excavators, Mini-excavators

|When your final drive quits working, there is some information you can put together that will help a technician diagnose the problem more quickly and accurately. In this Shop Talk Blog post, we are going to look at four questions you should ask before you send a final drive in for diagnosis or repair. Answering these questions will help you obtain a more accurate diagnosis of your final drive.

Final Drive Leaks

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Mini-excavators, Compact Excavators, Leaks

|One of the first signs of trouble with a final drive may be the presence of fluid where it shouldn’t be. Leaks will lead to final drive failure. In this Shop Talk Blog post, we are going to discuss how to identify possible sources of leaks and the types of fluid involved.

How to Flush Your Hydraulic System

Final Drive, Final Drive Motor Maintenance, Final Drive Maintenance, Excavators, Mini-excavators, Hydraulic System

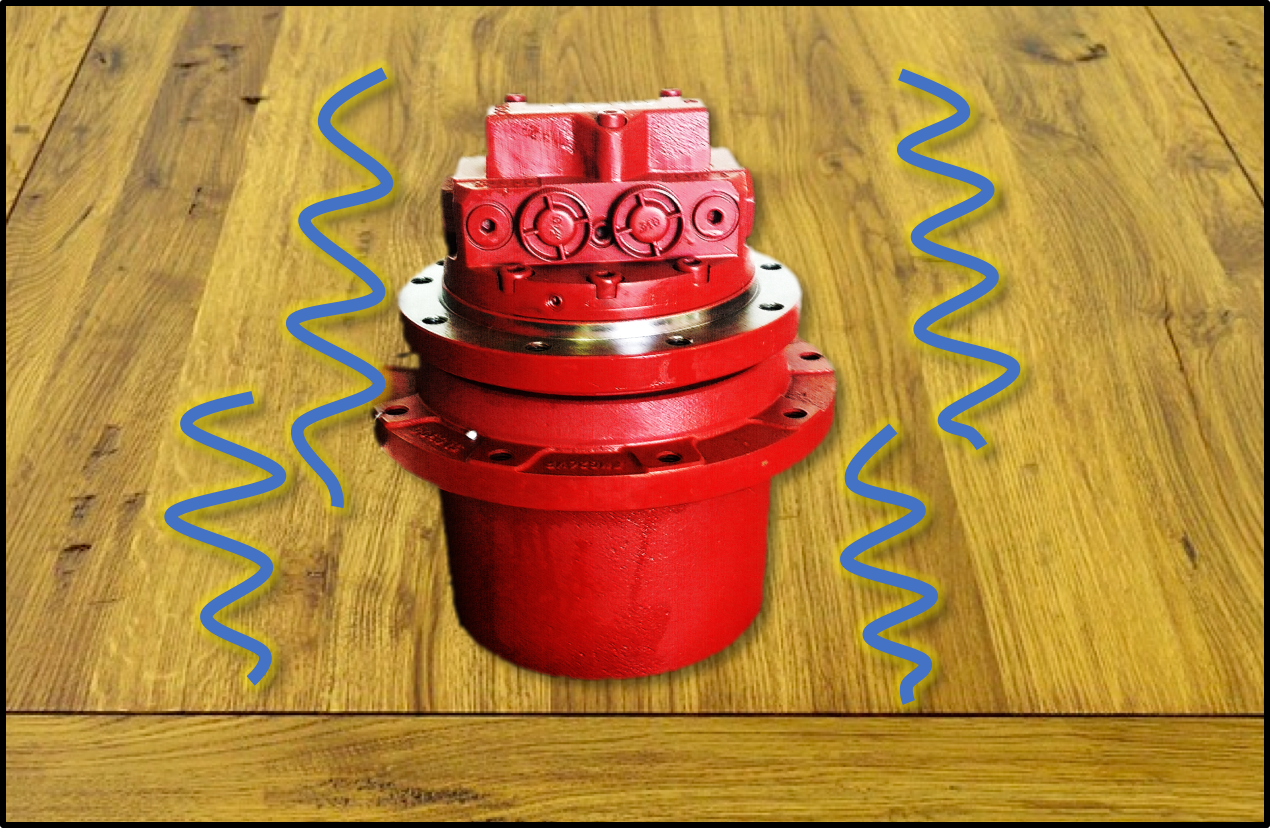

|How to Troubleshoot a Noisy/Vibrating Final Drive Motor

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Excavators, Mini-excavators

|Have you or one of your operators noticed that your final drive motor is vibrating excessively or has become a little too noisy for it to be normal? In this Shop Talk Bog post, you'll learn step by step how to troubleshoot a noisy or vibrating hydraulic motor and what steps you need to take to keep your equipment running.

Final Drives Spinning Backwards

Final Drive, Excavators, Mini-excavators, Final Drive Installation, Spinning

|One of the common questions we get asked is this: why is my final drive spinning backwards? In this Shop Talk Blog post, we'll talk about why final drives spin the wrong direction and some different approaches on how to fix the problem. This information holds regardless of whether it's on an excavator, skid steer loader, or compact track loader.

Hydraulic Fluid Injection - Do You Understand the Dangers?

Final Drive, Final Drive Failure, Hydraulic Motors, Final Drive Maintenance, Heavy Equipment Safety, Hydraulic Pumps, Safety, hydraulic connections, hydraulic ports

|Hydraulic fluid may seem relatively harmless to work with -- until it is pressurized. In this Shop Talk Blog post, we are going to take a look at why hydraulic fluid under pressure is so dangerous, what happens when you come into contact with it, and what you can do to minimize those dangers when you're on the job.

Note: If you're working with pressurized hydraulic fluid and feel a prick (like electricity) on your skin, please seek medical attention right away.

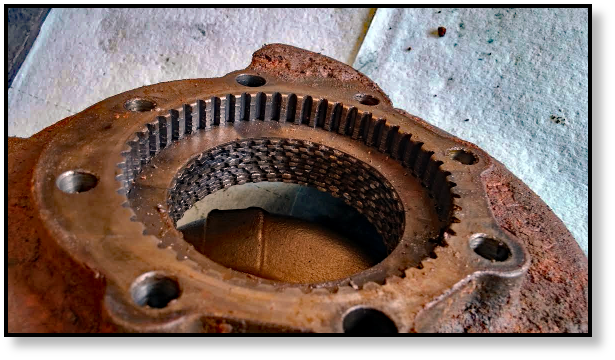

How To Fix a Final Drive Brake Assembly

Final Drive, Final Drive Failure, Final Drive Maintenance, Brakes

|If you have a Bobcat T180, Bobcat T190, or Bobcat T140 compact track loader, you may eventually need to replace the brake pack. In this Shop Talk Blog post, we are going to talk about what the brake pack is, how it works, signs of wear, and what to expect when it comes time to replace it ... complete with a video from Dr Drive himself!