Is your final drive gear box overheating? Is it hot to the touch, or does it steam when water comes into contact with it? That could be the sign of some serious problems that you need to investigate. In this Shop Talk Blog post, you'll learn step by step how to properly troubleshoot problems with an overheating gear box on your final drive motor.

How to Troubleshoot an Overheating Gear Box on Your Final Drive

Final Drive, Final Drive Motor Gearbox, Final Drive Motor Gears, Excavators, Mini-excavators, Gear oil

|Identifying the Hydraulic Ports on a Final Drive Motor

Final Drive, Hydraulic Motors, Excavators, Mini-excavators, hydraulic connections, hydraulic ports

|There can be up to five hydraulic connections to your final drive motor or travel motor, and this is true whether you have a mini-excavator, skid steer loader, or compact track loader. In this Shop Talk Blog post we will discuss each hydraulic port, including how to identify them and what their purposes are.

Summer Safety: 6 Ways to Protect Against the Summer Heat

Final Drive, Excavators, Mini-excavators, Heavy Equipment Safety, Safety

|It's summer -- and here in Texas, that means it going to be hot and humid! Heat is dangerous, though. And because we care about our readers, we've put together some tips on how to protect yourself against the summer heat. We hope this Shop Talk Blog post helps you keep cool in the hot summer temperatures!

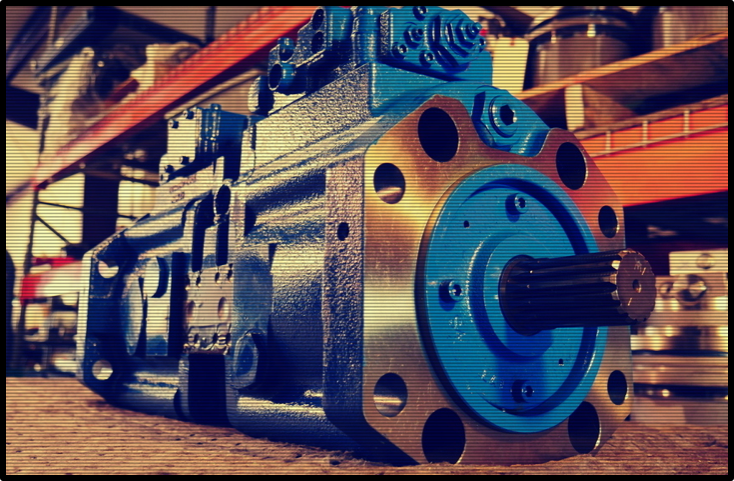

Replacing a Hydraulic Pump? Consider These 4 Things Before You Do!

Final Drive, Heavy Equipment, Excavators, Mini-excavators, Eaton Hydraulic Pumps, Hydraulic Pumps

|The main hydrostatic pump is what keeps your machine moving -- without hydraulic flow and pressure, your machine comes to a halt. Everything else may be in perfect operating order (including the final drive motors!), but work stops when the main hydraulic pump goes out. In this Shop Talk Blog post we are going to discuss some things you need to consider when it comes time to replace a hydraulic pump.

Does Your Excavator Need an Eaton Track Drive Motor?

Final Drive, Hydraulic Motors, Eaton Hydraulic Motors, Excavators, Mini-excavators, Mining, Agriculture, Construction, forestry, Eaton track drive motor

|When the track drive motor on your exacavtor goes out, you need a quality replacement that fits your budget and your machine. If you own a hydraulic excavator, one of your newer options here in the United States is an Eaton brand aftermarket track drive motor. In this Shop Talk Blog post, we are going to discuss the pros of the Eaton JMV Series Track Drive Motors.

What to Know Before You Order a Final Drive

Final Drive, Final Drive Failure, Final Drive Motors, Excavators, Mini-excavators, Construction

|When your work has come to a grinding halt because of a failed final drive, you need to get a replacement as soon as possible -- and you want to get the right final drive motor the first time. In this Shop Talk Blog post, we are going to look at what information you should have on hand before you start shopping for a replacement drive motor.

4 Questions to Ask When Replacing a Final Drive

Final Drive, Final Drive Failure, Reman Final Drives, Final Drive Motors, Hydraulic Motors, Final drives, Rebuilt Final Drive Motor, Eaton Hydraulic Motors, Excavators, Mini-excavators, Final drive motor, Hydraulic drive motor, CAT Equipment, Bobcat Equipment, Construction

|You're pressed for time already, and now one of your final drives has stopped your equipment in its tracks. You need a replacement, and you need it fast. In this Shop Talk Blog post, we are going to discuss 4 important questions you need to ask when you are about to replace your final drive or hydraulic motor. Taking the time to get answers to these questions will save you trouble (and possibly money) in the long run.

Reman Final Drives and Lapping- Dr Drive Shop Video

Final Drive, Hydraulic Motors, Heavy Equipment 101, Final drive motor, Hydraulic drive motor

|Texas Final Drive and Lapping Tables

One of the tools used to restore certain final drive components to usability at Texas Final Drive is a lapping table. Lapping is a manufacturing process that produces a smooth, flat surface on a part. The particular process we use for final drive parts is officially termed free abrasive lapping. In this Shop Talk Blog post, we are going to talk about the lapping process and how it applies to final drive motors.

Autopsy: Hy-Dash Final Drive Motor

Final Drive, Final Drive Failure, Final Drive Motor Gearbox, Final Drive Maintenance, Heavy Equipment 101, Hy-dash Final Drive

|A customer sent in a Hy-Dash brand final drive in for repairs. The symptoms were quite simple: the tracks on one side of the machine had been losing power and finally refused to move, so he pulled the track drive and brought it to us. In this Shop Talk Blog post, we are going to look at what caused this kind of catastrophic failure and how you can avoid a similar fate.

The Cool History of ASV

Final Drive, Final Drive Motors, Hydraulic Motors, Heavy Equipment, Heavy Equipment 101, Excavators, Mini-excavators, Hydraulic drive motor, ASV Equipment

|ASV Compact Equipment

You are probably familiar with the ASV brand of compact equipment, which focuses primarily on multi-terrain loaders and skid steer loaders. What you may not be familiar with, however, is the history of ASV and how it has impacted the compact equipment market through the years. In this Shop Talk Blog post, we are going to step back in time and check out the cool history (pun intended!) of ASV.