Here at Texas Final Drive, our technicians have rebuilt and repaired thousands of final drives. Through the years, we’ve seen first hand the results of equipment owners following bad advice when it comes to gear oil. Here are three examples of the worst advice we’ve heard about gear oil and final drive hydraulic motors.

Worst Advice We've Ever Heard about Gear Oil

Final Drive, Final Drive Maintenance, Gear oil, Maintenance

|5 Common Hydraulic Motor Questions Answered

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Motors, Final drives, Final Drive Maintenance

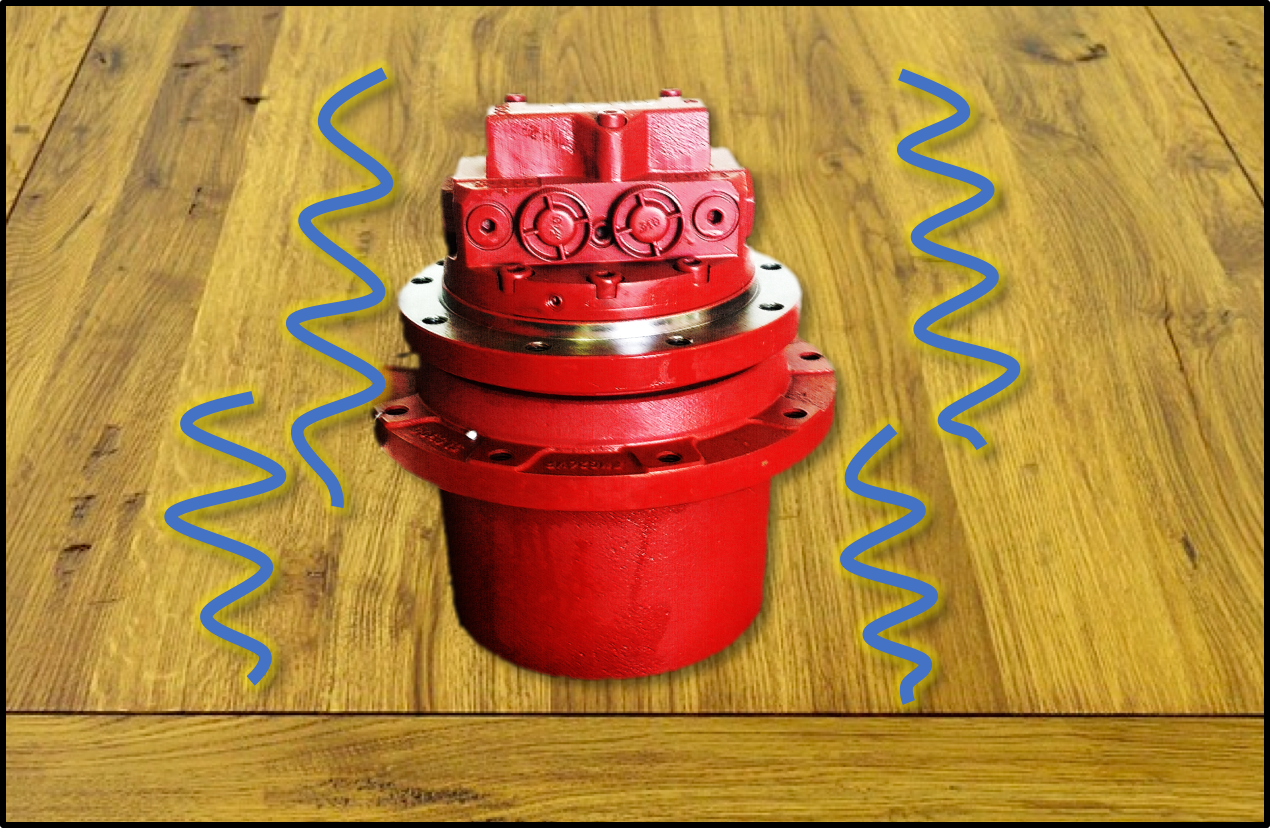

|In this Shop Talk Blog post, we are going to discuss the answers to five very common questions about hydraulic motors: what is a case drain, how do hydraulic motors fail, what exactly is displacement, how are hydraulic motors rated, and how does a hydraulic motor differ from a final drive?

Final Drive Maintenance with Dr. Drive!

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Final drive motor, Maintenance, Preventative Maintenance

|

Maintenance is never a popular subject - especially when you have deadlines looming over your head. But you NEED to do your maintenance! In this Shop Talk Blog post, we'd like to help you keep a healthy perspective on the subject of maintaining your final drives, track motors, and hydraulic motors by discussing two major maintenance steps you should never, ever neglect.

Troubleshooting Final Drive Problems - Eliminating External Causes

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance

|Maintaining the Final Drive on Your Excavator

Final Drive, Final Drive Motor Seals, Final Drive Motors, Final Drive Maintenance, Excavators, Mini-excavators, Compact Excavators

|Final Drive Leaks

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Mini-excavators, Compact Excavators, Leaks

|One of the first signs of trouble with a final drive may be the presence of fluid where it shouldn’t be. Leaks will lead to final drive failure. In this Shop Talk Blog post, we are going to discuss how to identify possible sources of leaks and the types of fluid involved.

How to Flush Your Hydraulic System

Final Drive, Final Drive Motor Maintenance, Final Drive Maintenance, Excavators, Mini-excavators, Hydraulic System

|How to Troubleshoot a Noisy/Vibrating Final Drive Motor

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Excavators, Mini-excavators

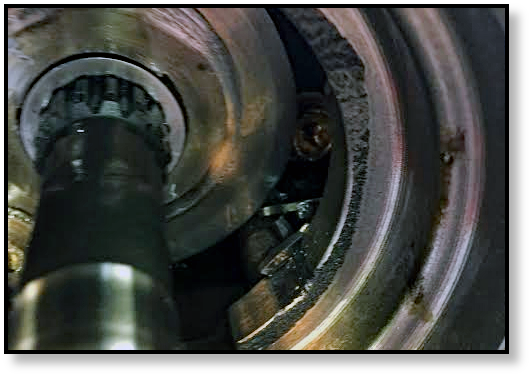

|Have you or one of your operators noticed that your final drive motor is vibrating excessively or has become a little too noisy for it to be normal? In this Shop Talk Bog post, you'll learn step by step how to troubleshoot a noisy or vibrating hydraulic motor and what steps you need to take to keep your equipment running.

Hydraulic Fluid Injection - Do You Understand the Dangers?

Final Drive, Final Drive Failure, Hydraulic Motors, Final Drive Maintenance, Heavy Equipment Safety, Hydraulic Pumps, Safety, hydraulic connections, hydraulic ports

|Hydraulic fluid may seem relatively harmless to work with -- until it is pressurized. In this Shop Talk Blog post, we are going to take a look at why hydraulic fluid under pressure is so dangerous, what happens when you come into contact with it, and what you can do to minimize those dangers when you're on the job.

Note: If you're working with pressurized hydraulic fluid and feel a prick (like electricity) on your skin, please seek medical attention right away.

How To Fix a Final Drive Brake Assembly

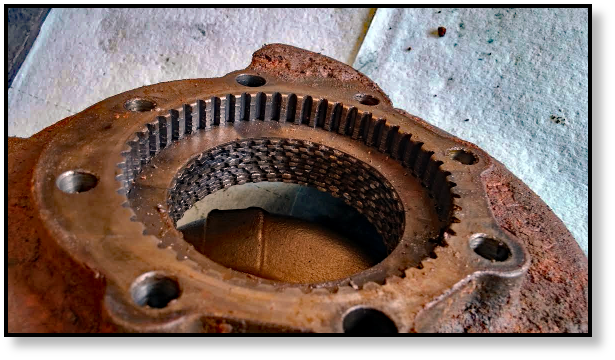

Final Drive, Final Drive Failure, Final Drive Maintenance, Brakes

|If you have a Bobcat T180, Bobcat T190, or Bobcat T140 compact track loader, you may eventually need to replace the brake pack. In this Shop Talk Blog post, we are going to talk about what the brake pack is, how it works, signs of wear, and what to expect when it comes time to replace it ... complete with a video from Dr Drive himself!