If your tracks don't move that easily anymore or your machine starts to steer to one side, it could be that your gear teeth on your drive shaft have been worn down; this is what is known as a "stripped drive shaft". One of the most common problems found on Kubota and Hy-Dash final drives involves a stripped drive shaft. In this Shop Talk Blog post, you’ll learn how to identify a few symptoms of a stripped drive shaft, what can be done about it, and how to prevent it from happening to your final drive.

Backhoe loaders can be seen on just about every major construction site you encounter. However, while they may common, their background and features may not be so well known. In this Shop Talk Blog post, we are going to discuss some of the more interesting facts about the backhoe loader.

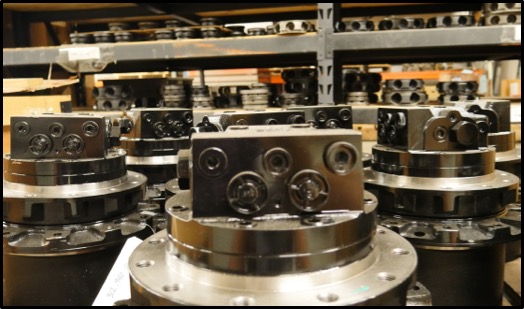

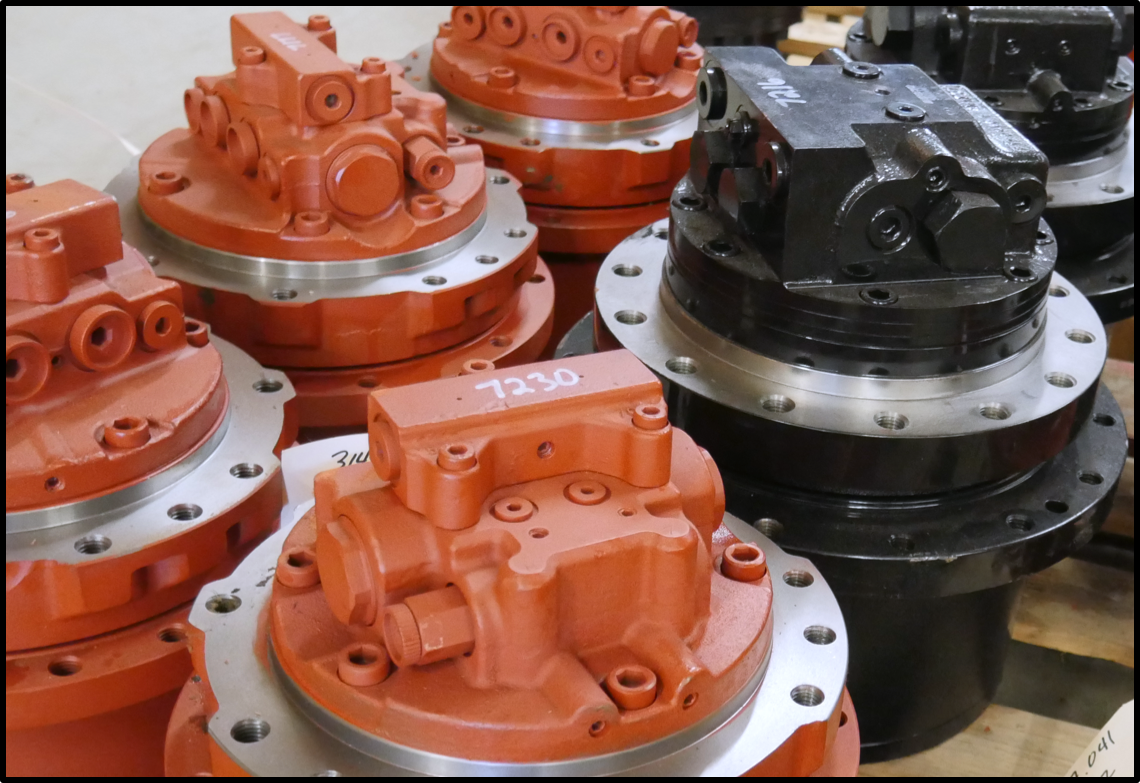

Sometimes you simply have no choice but to replace the final drive motors on your machine. Good final drives aren't cheap, either. There are many options to consider and questions to ask before you make a purchase, especially if you have a goal of saving time, money, and downtime later on. In this post, we are going to look at options for replacing a final drive, information you should have on hand before you start shopping for one, and what you need to look for in a replacement.

How Do I Fix My Final Drive?

Maintenance, Final Drive Diagnosis, Final Drive Problem

|In this Shop Talk Blog post, we are going to review some hints and tips for how to repair your own final drive. We'll begin with some guidelines for installation and removal, followed by taking your final drive apart and dealing with different types of repairs.

4 Quick Tips for Extending the Life of Your Final Drive

Final Drive, Final Drive Failure, Final Drive Motor Maintenance, Final Drive Maintenance, Maintenance, Preventative Maintenance

|Your final drive represents a significant investment, and it has to be functional for your equipment to run. In this Shop Talk Blog post, we are going to go over 4 things: minimizing contamination, keeping an eye on the gear oil, checking the case drain filter, and attending to leaks. Follow these 4 simple tips to get draw out the life of your final drive motor to the fullest!

What's Wrong With My Final Drive Motor?

Maintenance, Final Drive Diagnosis, Final Drive Problem

|You've got quite a bit of money invested in your final drive motors, and when they go down it impacts your entire operation and your bottom line. In this Shop Talk Blog post, we'll review common symptoms of final drive problems, what they mean, and how to troubleshoot them.

Compact track loaders are used everywhere from urban construction sites to dairy farms. For this Shop Talk Blog post, we are going to discuss answers to some common questions that come up about compact track loaders.

Guidelines to Final Drive Maintenance

Final Drive Maintenance, Maintenance, Preventative Maintenance, Predictive Maintenance

|Here at Texas Final Drive, we often seen first-hand what poor maintenance can do to an otherwise good hydraulic final drive motor. In this blog post, we are going to review the WHAT, WHEN, and HOW of good final drive maintenance.

Bobcat T190 Drive Shaft Bushings

Final drive motor, Final Drive Diagnosis, Final Drive Problem, Bushing

|In this Shop Talk Blog post, we are going to look at a Bobcat T190 drive shaft bushing that came into the shop. We’ll discuss the basics about bushings, their need for lubrication, what went wrong with this particular bushing, and how this affected final drive performance overall.

When your machine has stopped running (or literally stopped in its tracks), you need a final drive motor right away. Since final drive motors are large purchases, however, you need to do a bit of research first. That's likely how you ended up reading our post. Here are five questions you need to ask before you commit to buying a replacement hydraulic final drive -- from the experts!