Clogged case drain filters are responsible for a significant number of failed final drives and hydraulic motors that come into our shop here at Texas Final Drive. In this Shop Talk Blog post, we are going to talk about what case drain filters do, what happens when they clog, and how you can prevent case drain related failure from wrecking your final drive motor.

Recent Posts

Preventing Case Drain Related Failure on Final Drive Motors

Final Drive Failure, Hydraulic Motors, Final Drive Maintenance, Heavy Equipment 101, Excavators, Mini-excavators, Mining, Bobcat Equipment, Agriculture, Construction, forestry

|Does Your Excavator Need an Eaton Track Drive Motor?

Final Drive, Hydraulic Motors, Eaton Hydraulic Motors, Excavators, Mini-excavators, Mining, Agriculture, Construction, forestry, Eaton track drive motor

|When the track drive motor on your exacavtor goes out, you need a quality replacement that fits your budget and your machine. If you own a hydraulic excavator, one of your newer options here in the United States is an Eaton brand aftermarket track drive motor. In this Shop Talk Blog post, we are going to discuss the pros of the Eaton JMV Series Track Drive Motors.

What to Know Before You Order a Final Drive

Final Drive, Final Drive Failure, Final Drive Motors, Excavators, Mini-excavators, Construction

|When your work has come to a grinding halt because of a failed final drive, you need to get a replacement as soon as possible -- and you want to get the right final drive motor the first time. In this Shop Talk Blog post, we are going to look at what information you should have on hand before you start shopping for a replacement drive motor.

Eaton Hydraulic Pumps

Heavy Equipment, Eaton Hydraulic Motors, Excavators, Mini-excavators, Construction, Eaton Hydraulic Pumps, Case, Hydraulic Pumps, Volvo

|Texas Final Drive is excited to announce that we've started stocking Eaton Hydraulic Pumps!

5 Solid Resources for Learning About Compact Equipment

Heavy Equipment, Excavators, Mini-excavators, Construction, Resources

|If you are new to the compact equipment industry, or maybe it’s been a few years, we’ve got a list of resources to help you get up to speed and stay ahead of the curve. In this Shop Talk Blog post, we give you five excellent resources for learning more about compact equipment.

Reman Final Drives and Lapping- Dr Drive Shop Video

Final Drive, Hydraulic Motors, Heavy Equipment 101, Final drive motor, Hydraulic drive motor

|Texas Final Drive and Lapping Tables

One of the tools used to restore certain final drive components to usability at Texas Final Drive is a lapping table. Lapping is a manufacturing process that produces a smooth, flat surface on a part. The particular process we use for final drive parts is officially termed free abrasive lapping. In this Shop Talk Blog post, we are going to talk about the lapping process and how it applies to final drive motors.

Autopsy: Hy-Dash Final Drive Motor

Final Drive, Final Drive Failure, Final Drive Motor Gearbox, Final Drive Maintenance, Heavy Equipment 101, Hy-dash Final Drive

|A customer sent in a Hy-Dash brand final drive in for repairs. The symptoms were quite simple: the tracks on one side of the machine had been losing power and finally refused to move, so he pulled the track drive and brought it to us. In this Shop Talk Blog post, we are going to look at what caused this kind of catastrophic failure and how you can avoid a similar fate.

Komatsu: Four Facts We're Betting You Don't Know

Heavy Equipment, Heavy Equipment 101, Hydraulic drive motor, Komatsu

|Komatsu History

Komatsu is right behind Caterpillar in the list of the world's largest manufacturers of mining and construction equipment. There are some interesting trivia involved in its history, as with almost all of the history of heavy equipment manufacturers. This Shop Talk Blog post takes a look at some interesting tidbits of trivia about this leader in heavy, compact, and off-road equipment.

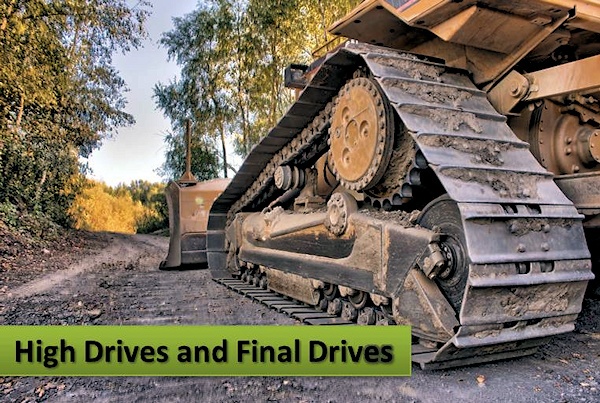

Caterpillar Equipment: High Drives and Final Drives

Final Drive, Final Drive Motor Gears, Heavy Equipment 101, Final Drive Motor Technology, Excavators, Hydraulic drive motor, CAT Equipment, CAT Parts

|Hydraulic Motors with Integrated Gear Reduction System

You may have noticed on many tracked machines -- especially on compact track loaders and multi-terrain loaders -- that the drive sprocket is set high, by which we mean it is elevated above the ground line. There's a good reason for that, and in this Shop Talk Blog post we are going to discuss the advantages, as well as disadvantages, of this design -- and take at how it led to the development of hydraulic motors with an integrated gear reduction system.

Bobcat Mini Excavator Findings

In this Shop Talk Blog post, we are going to review the "autopsy" findings for a mini-excavator final drive taken off a Bobcat 331. We'll go through this step-by-step, just like the technician who disassembled and inspected this hydraulic drive motor.