Final Drive and Hydraulic Motor Secrets

Final drives and hydraulic motors are key to keeping your heavy equipment moving and when one fails the machine it's on comes to a grinding halt (pun intended). In this Shop Talk Blog post, we are going to tell you the three secrets to destroying a final drive. Are you ready?

Want to learn more? Check out these other posts from the Shop Talk Blog:

- 2-Phase Testing and Quality Assurance for Hydraulic Motors

- Effectively Cleaning a Final Drive

- 5 Reasons a Final Drive Can Lack Power

Final Drive Disaster Step #1: Ignore Leaks

A little leak never hurt anyone, right? Why not just top off the fluid level and keep running? Because that truly is one of the best ways to destroy a final drive.

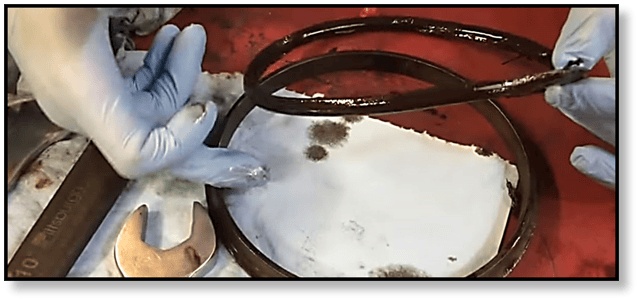

Leaking seals not only allow key fluids to drain out of the final drive, but they allow damaging contaminants -- whether the leak is on the hydraulic side or the planetary side -- to make their way into the final drive. Sand, dirt, grit, and similar particles will wreak havoc on the gears and bearings that help transfer power in your final drive.

Obviously, the loss of hydraulic fluid will compromise the performance of your final drive and, if left untreated, will seriously damage it. When gear oil leaks out of the planetary hub, it leaves gears and bearings exposed to metal-on-metal contact and can cause extreme increases in temperature.

Final Drive Disaster Step #2: Never Check the Case Drain Filter

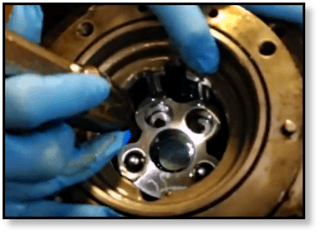

As you know, the case drain returns hydraulic fluid to the pump via a low-pressure line with an in-line filter. When that filter becomes clogged with contaminants, the pressure in the case drain line increases dramatically from its normally low pressure.

That pressure must go somewhere, resulting in things like blown seals, damage to the rotator group, hydraulic fluid in the planetary side of the drive, and finally a cracked or blown final drive cover. When the pressure reaches the point that it can crack a cast iron cover plate, it puts your operators and technicians in danger.

Ignoring the case drain filter is one of the most efficient ways to destroy a final drive, and maybe even get someone injured.

Final Drive Disaster Step #3: Never Change the Gear Oil

Experts will tell you that the gear oil should be changed at least once a year and checked about once every 100 hours. There just trying to sell their expensive gear oil, right? Maybe not.

Experts will tell you that the gear oil should be changed at least once a year and checked about once every 100 hours. There just trying to sell their expensive gear oil, right? Maybe not.

When you do not change out the gear oil on a regular basis, you end up with a thick sludge that does little to lubricate and protect the key components in the planetary side of your final drive. This obviously leads to damage not unlike what stems from having no gear oil in your final drive at all. You also should not mix different grades of gear oil because it will compromise its performance. Don't forget that we carry our own brand of gear oil now!

How to Protect Your Final Drive

Now that we’ve covered three ways to quickly destroy a final drive, let’s talk about the opposite: how you can extend the life of your final drive as long as possible.

You can start by following manufacturer recommendations for checking and changing out the case drain filter. Next, never ignore leaks! Finally, change the gear oil and take care not to mix different grades of oil together. When a leak develops, get those seals replaced as soon as possible to protect the investment you have in your final drive.

For a quick resource guide to addressing gear oil leaks check out the 6 Fascinating Facts About Gear Oil (free infographic) from Texas Final Drive.