Your CTL (Compact Track Loader) depends on the final drive motors to keep it running. When a final drive fails, costs include repair/replacement and expensive downtime. Extending the useful life of your final drives reduces downtime and repair costs, meaning a better profit margin and more productivity.

In this Shop Talk blog post, we’ll look at tips for extending the life of CTL final drives, focusing on maintenance and inspection, operating practices, and track tension and alignment.

Here are a few other Shop Talk blog posts you might find useful:

- CTL / MTL Undercarriage Basics

- Self Driving Track Loaders

- CTL Final Drives: 5 Signs They Need Service

Tip #1: Make Maintenance and Inspection a Priority

Follow the manufacturer's recommended maintenance schedule to ensure proper lubrication and identify potential problems early. We recommend checking your gear oil levels about every 100 hours of operation and changing the gear oil at least once a year. If you have to keep topping off the gear oil when you check the levels, you have a leak that must be addressed. And if your gear oil is nasty when you change it, it should be changed more often.

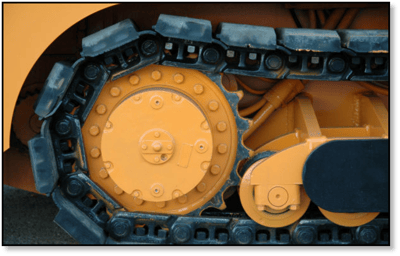

Also, regularly inspecting the final drive is a good idea. Check for leaks, damaged seals, and cracks in the hub. Finally, keep the exterior of the final drive and undercarriage clean by removing dirt and debris that can get packed around the drive motor and potentially damage mechanical face seals. Never ignore a leaking seal because it allows contamination to enter and critical fluids to leak out. Leaks don’t ever get better - they only get worse.

Tip #2: Use Industry Best Operating Practices

Maintenance isn’t the only way to extend the life of your final drive motor. Experts recommend that you minimize spinning and counter-rotating. Turning with three-point turns reduces stress on the final drive and tracks. Shock loads can also be problematic: smooth operation, gradual acceleration, and deceleration protect the drive components. Experts also say high speeds increase wear and tear on the drive system, so lower speeds should be used when possible.

It’s also a good idea to, when possible, travel on firm, level surfaces: Excessive stress on uneven terrain can wear the final drive prematurely. However, we know that isn’t always feasible for some types of applications.

Tip #3: Maintain Track Tension and Alignment

Maintaining proper track tension is essential to your tracks and final drives because over-tightening can damage the final drive. If the tracks on your machine are too tight, it can cause the final drive motor to seem weak.

Misaligned tracks also strain the final drive, so check alignment regularly. We recommend adjusting the track tension and alignment according to the manufacturer's instructions if they’re available.

Some Additional Tips

Consider investing in undercarriage protection. Guards and shields can help prevent damage from debris and rocks. Avoid storing your CTL long-term in extreme temperatures or harsh conditions when possible. And during the winter months, don’t let ice build up on the track: not only is it heavy, but water expands when it freezes.

Conclusion

Your final drive motors keep your CTL moving, and the longer their lifespan, the more costs you’ll save in repair and downtime. We hope you’ve found these tips helpful, and if you have any questions about Final Drive motors, contact us at Texas Final Drive Motors.