Mechanical fasteners join things together, whether bolts holding the hubs of your final drive motor together or a circlip used to keep the cover plate in place. In this Shop Talk Blog post, we’ll explore the different types of fasteners you may find in your final drive motor.

Table of Contents

Bolts

My first introduction to nuts and bolts came young with the Ideal Bolt and Play Building Set. I figured out that nuts and bolts hold things together. In the real world, when specified and installed correctly, bolts can hold components together with massive forces or pressures trying to separate them.

Basic Bolt Dimensions

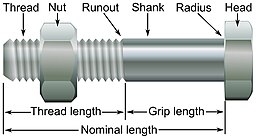

For review, here are the basic dimensions of a bolt:

- Thread

- Runout

- Shank

- Radius

- Head

Source: Mikael Häggström, CC0, via Wikimedia Commons

Note that the nominal length of the bolt extends from the head's inside surface to the bolt's end. The nominal length includes the thread length and the grip length (the part of the bolt that doesn’t have threads). Bolts also have a small radius where the shank meets the head to prevent a stress concentration.

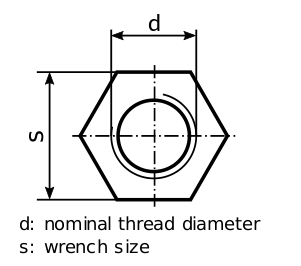

Source: By Undfuld35 - Own work, CC0, Wikimedia Commons

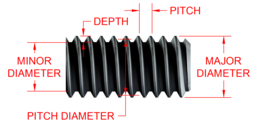

Another important aspect of bolt dimensions is the bolt head itself, as illustrated above. More crucial than the bolt head, however, are the thread dimensions. In the image below, you can see the

- Pitch

- Major diameter

- Minor diameter

- Pitch diameter

- Depth

Source: Robert Hewitt, CC BY-SA 3.0 via Wikimedia Commons

How Bolts Work

When the nut is tightened, it moves along the bolt threads (which act like tiny inclined planes) to close the gap between the fastened parts. As the bolt is torqued, it develops a tension force along the length of the bolt. This causes the bolt to act as a spring (which is also why they can come apart quite violently when they break).

This spring force acts as a clamp holding the two components together. When the nut is loosened, that clamping force is released. This clamping force also evenly distributes the load across the components it is fastening together, preventing material deformation.

Don't forget that an important aspect of how bolts work invovles torquing and the order in which they are torqued -- and the benefits of using a threadlocker.

Bolt Strength Grades

Steel bolts are available in different strength grades.

SAE Bolt Grades: This is the primary standards for bolt strength grades in the US and are set according to a system developed by the SAE (Society of Automotive Engineers). The SAE marking system uses raised dashes on the bolt head. These raised dashes are used to indicate strength. Here is a table explaining SAE bolt grade symbols.

Metric Bolt Grades: Metric bolt grades are set according to ISO (International Standards Organization) rules. The grades consist of two numbers separated by a dot, and the property class is expressed in raised or depressed numbers found on the top or on the side of the bolt head. Here is a table explaining metric bolt grades.

ASTM Bolt Grades: The ASTM (American Society for Testing and Materials) established the rules for these bolts. A combination of letters, numbers, and lines indicates the strength grades. You can find more information about these in this table explaining ASTM bolt grades.

Ensuring that you're using the right strength grade bolts with your final drive can help reduce the chances of failure.

How Bolts are Classified

There are several different ways to classify bolts, and you’re probably familiar with them all.

Standard vs Metric: Bolts are classified by the standard they follow: metric, measured in millimeters, or imperial, measured in inches. The standards also affect the thread pitch or the distance between threads. That’s why forcing a standard nut on a metric usually results in stripped threads.

Head Type: Bolts can have different head types, such as hexagonal, square (which reminds me of Erector Sets), Phillips, slotted, socket, etc. The head type usually determines how the bolt will be tightened/loosened: wrench, socket, or screwdriver, for example.

Bolt Size: Bolts are also classified by size, including their diameter, length, and thread pitch.

Thread Coverage: Some bolts are fully threaded with little to no grip length, while others are partially threaded. The choice between these depends on the specific application and the materials being fastened.

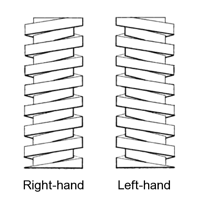

Thread Direction: As you know, most bolts are right-hand threaded, meaning they tighten clockwise. However, left-hand threaded bolts exist and tighten counter-clockwise. You’ll usually see them in specific applications to prevent loosening due to the direction of movement.

Source: Eugene Wycliffe Kerr, Public domain, via Wikimedia Commons

Bolt Materials

Bolts are made from carbon steel, stainless steel, alloy steel, titanium, aluminum, and even plastic. The choice of material depends on the application, required strength, and environmental conditions. And the material used affects the strength grades. Bolts can also be coated to enhance their durability and resistance to corrosion. Zinc plating, galvanizing, and black oxide are common bolt coatings, and the choice of which to use heavily depends on their working environment.

Washers

While not strictly fasteners, washers are often used with bolts to (1) better distribute the clamping force and/or (2) ensure the nut or bolt head is pressed against a smooth surface to help prevent gradual loosening over time.

What Can Washers Do

What can washers do within a final drive motor?

- Distribute the load of a threaded fastener

- Lock the fastener to reduce the chances of it working loose over time

- Protect surfaces from potential damage caused by a washer

- Absorb vibrations

- Prevent leaks in a joint

Types of Washers

As you can see below, there are many different types of washers. Let's focus on the washers you will most likely encounter in a final drive motor.

By ArnoldReinhold at the English-language Wikipedia, CC BY-SA 3.0, Wikimedia Commons

Flat washers serve several purposes, such as distributing the clamping force, protecting the surface of fastened items, and correcting the size of an opening. As the name implies, they are flat (unlike Belleville or wave washers), and their dimensions are described in terms of thickness, inner diameter, and outer diameter. They are available in many different sizes, materials, and finishes. Plain washers are similar to flat washers but are thicker. They can also distribute the load better because they provide a greater surface area.

Lock washers are used to further prevent nuts and bolts from coming loose, either through rotation or a loss of friction and have some spring-like tab to help lock them in place. Split washers are split with each end bent outward and in opposite directions. These are also called helical washers. When fully tightened, one end digs into the nut/bolt while the other digs into the mating surface.

The external tooth lock washer is more star-shaped, with teeth on the outside diameter to “bite” into the fastener. They are often used when a wide-headed fastener is involved. There are also internal tooth lock washers that also dig into the fastener when fully tightened. They have two common uses: situations where there is a lot of shock and vibration and applications where a shallow-headed fastener needs to be locked into place.

There are several types of spring washers, which enable them to move with vibrations and apply a flexible pre-load to a bolted joint.

Belleville washers are flat washers that have been pressed into a cone shape, which is why they are sometimes called conical spring washers. They have beveled sides that can support heavy forces with very little deflection. These washers can also be stacked in different configurations to provide different spring characteristics. You’ll usually see Belleville washers used in higher-friction applications where shock and vibration effects can cause fasteners to loosen. They are also used in applications where significant temperature changes can affect the clamping force. How much they can deflect depends on the ratio of their height and to their thickness.

Crescent washers, like Belleville washers, are designed for lighter loads and have the same spring rate throughout their deflection range. They work best for applications where loads vary cyclically and are often used to absorb movement.

Dome spring washers look like Belleville washers but have rounded sides and can handle much higher loads. You often see them in situations that could use a crescent washer but need a more flat bearing surface.

Another type of spring washer you might encounter are wave washers. They are curved in two directions to achieve a wave-like shape and can behave as a spring when compressed. The spring effect helps to maintain the clamping force of the fastener. However, they are typically used in low-strength applications.

When Mechanical Pins Are Used

Here are some typical examples of when mechanical pins should be used:

- A permanent joint is not required and the objects to be joined need to be able to be disassembled easily

- The objects to be joined are subject to vibration or shock, which is common in applications such as hydraulic pumps and final drives

- The objects to be joined are made of different materials

- The objects need to be precisely aligned for the best performance

Pins

Pins, such as dowel or cotter pins, are used to fasten two or more parts together and are usually implemented in conjunction with holes in the fastened parts, as you can see below where a cotter pin is used to secure the clevis pin in place. In addition to fastening, they can also aid in alignment and prevent parts from moving.

Source: I, Sakurambo, CC BY-SA 3.0, via Wikimedia Commons

Types of Pins

Here are some of the different types of pins:

Coiled pins: Coiled pins are similar to slotted pins, but the sheet metal is coiled into a spiral. This makes them more resistant to pulling out.

Cotter pins: A cotter pin, or a split pin or cotter key, is used to secure a nut or bolt. They are inserted through the hole in the nut or bolt, and the tines are bent in opposite directions to prevent the pin from coming out. Cotter pins are typically used when the nut or bolt is subject to vibration or shock.

Dowel pins: Dowel pins are solid cylindrical pins used to align two objects or prevent them from rotating.

Grooved pins: Grooved pins have three or more grooves along their length. These grooves interfere with the hole's walls, making removing the pin more difficult.

Slotted pins: Slotted pins are made from sheet metal rolled into a cylinder. They have a slot running along their length, which allows them to be inserted and removed easily.

Spring pins: Spring pins are made from spring steel. They have a coil spring inside that expands when the pin is inserted. This makes them self-locking, so they do not need to be secured with a nut or washer.

Circlips

Source: Oxensepp at German Wikipedia, CC BY-SA 2.0 DE, via Wikimedia Commons

Circlips are great until they bend or you don't have the right tools to get them out. That can create some problems -- but otherwise, they do an excellent job.

What is a Circlip?

A circlip, also known as a retaining ring, snap ring, or C-clip, is a mechanical fastener used to retain components on a shaft or in a bore.

It's basically a semi-flexible metal ring with open ends that can be placed into a machined groove on the shaft or bore. Once in place, the circlip prevents the component from moving axially (in or out).

Types of Circlips

The simplest types of circlips are internal and external. Internal circlips fit inside a housing or shaft. They have two open ends and are bent to form a U-shape. You'll typically see this used to retain a component in a bore.

External circlips are designed to fit around a bore. Like the internal circlip, they have two open ends that are bent, but they form more of a C-shape than a U-shape. These circlips you'll see retaining a component on a shaft.

A Circlip in a Final Drive Motor

The most common type of circlip is a plain wire ring, as seen in the video below, but there are also circlips with lugs or ears that make them easier to install and remove.

In this video, a simple wire circlip is doing a fantastic job of holding this Kayaba cover plate from a Kubota KX121 in place -- it's so hard to remove that maybe it's doing too good of a job.

Conclusion

The fasteners in your final drive motor are critical to its correct operation and performance. If you have any questions about them (e.g., right one ot use, how to remove, etc.) send us an email or give us a call.