When hurrying to reassemble your final drive motor, it’s tempting to torque one bolt and move on to the next adjacent bolt. But that isn’t a wise choice. In this Shop Talk Blog post, we’ll discuss why the sequence in which you tighten bolts is important and then look at what can go wrong when you don’t.

.png?width=600&height=600&name=Bolt%20Torquing%20Sequence%20for%20Final%20Drive%20Motors%20(4).png)

Here are a few other Shop Talk Blog posts you might enjoy:

Bolts fall under the category of mechanical fasteners whose job is to hold things together. Bolts not only hold your final drive together, but they also hold your drive motor to your machine. We know they must be extremely strong, considering the massive pressure within your final drive. However, how you install and torque them can compromise their ability to hold things together.

Importance of Tightening Bolts in a Sequence

Here are the three key reasons why bolt tightening sequence is important:

- Achieve uniform load distribution

- Avoid part distortion

- Achieving a good seal

When bolts are in the correct sequence, uniform load distribution is achieved. Each bolt carries approximately the same load, which can be critical when high pressures and forces are involved, like the ones that try to force final drive hubs apart. This is especially important when a gasket is involved.

Here’s another aspect of uniform load distribution: flanges need to come together slowly and be parallel. To achieve this, the correct sequence is needed, and several tightening passes are needed, increasing the load each time.

When the load is uniformly distributed, part distortion is minimized, like warping or deformation. We’ve probably all experienced this when working with plastic or sheet metal.

If you're fastening the hubs of your final drive together, you want to connection to be strong and reliable -- and that often involves a good seal. If the bolts aren’t carrying a uniform load, gaps between the surfaces may allow contaminants in and fluids out.

What Can Happen When an Improper Sequence is Used

So what happens when an improper bolt tightening sequence is used? Well, we talked about the importance of a uniform load distribution. An uneven load distribution can cause some areas to be under much higher stress than others, leading to premature failure.

For thick flanges, distortion may seem unlikely until you consider the extreme temperatures and forces involved during daily use. And distortion can lead to incorrect functionality and even premature failure. And warping can affect the seal achieved between the two mating surfaces, leading to leaks of pressure or fluid that only occur when your equipment has been running for a while.

Another potential problem that stems from improper sequencing involves the possibility of misalignment, which can impact performance and functionality. And, as discussed with distortion and sealing, it may only show up once the parts involved have heated up during use.

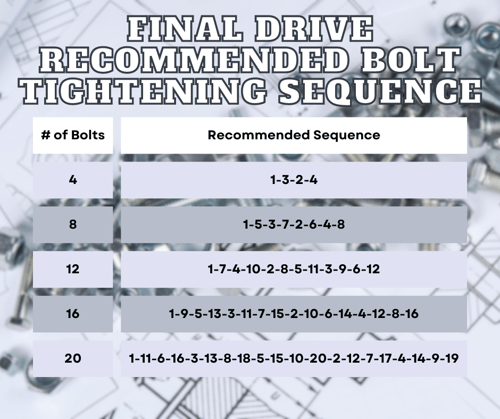

Bolt Torque Sequence

An official ASME PCC-1-2019 standard is considered the “go-to” documentation for bolting standards related to flange joints. Its full title is “Pressure Boundary Bolted Flange Joint Assembly,: but it’s 114 pages long -- so let’s just summarize best practices here in this infographic:

Conclusion

Taking the time to tighten bolts in the recommended sequence contributes to the health and performance of your final drive motor. And don't forget that here at Texas Final Drive we also use Loctite Threadlocker on bolts to further ensure their integrity and reduce potential corrosion issues.