Final Drive "Bites the Dust"

When the final drive on your Komatsu bites the dust, you start looking for repair and replacement options. In this Shop Talk Blog post, we are going to take a look in detail at one particularly popular replacement option: reman/rebuilt final drives.

Why Consider Reman or Rebuilt Final Drives

Without a working final drive, you Komatsu won't be going anywhere. The final drive is one of the key components in the power train, and its job is to convert torque to traction so that your machine can move. It will eventually wear out, but just because it has ceased to operate doesn't mean the entire final drive is a loss.

If your final drive has been reasonably maintained, it may only require a few replacement parts, such as bearings and seals, and a bit of a tune up. If its not extensively damaged, there's a good chance that the damage is isolated to certain parts that can be restored or replaced. You could just get repairs done, but there is no way of knowing how quickly your final drive may fail again. However, depending on where you send your final drive, if you have your final drive reconditioned -- resulting in a rebuilt final drive or a reman hydraulic motor -- you will have a longer lasting drive.

If your final drive has been reasonably maintained, it may only require a few replacement parts, such as bearings and seals, and a bit of a tune up. If its not extensively damaged, there's a good chance that the damage is isolated to certain parts that can be restored or replaced. You could just get repairs done, but there is no way of knowing how quickly your final drive may fail again. However, depending on where you send your final drive, if you have your final drive reconditioned -- resulting in a rebuilt final drive or a reman hydraulic motor -- you will have a longer lasting drive.

Komatsu Rebuilds

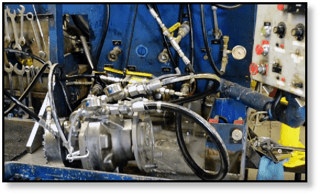

One of the drives that recently came into the shop here was a Komatsu D39 bulldozer final drive. The final drive was cleaned thoroughly inside and out and carefully inspected. All bearings, seals, o-rings, and gaskets were replaced with new one. Other parts were examined and graded as either acceptable for re-use or not. Unacceptable parts were either replaced or reconditioned (this depends on the type of part, extent of wear, etc.). The Komatsu final drive was then reassembled.

One of the drives that recently came into the shop here was a Komatsu D39 bulldozer final drive. The final drive was cleaned thoroughly inside and out and carefully inspected. All bearings, seals, o-rings, and gaskets were replaced with new one. Other parts were examined and graded as either acceptable for re-use or not. Unacceptable parts were either replaced or reconditioned (this depends on the type of part, extent of wear, etc.). The Komatsu final drive was then reassembled.

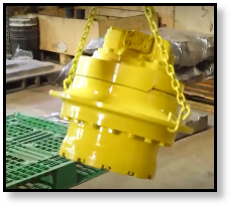

Once it was reassembled, it was thoroughly tested for leaks and performance in a two-phase, documented process. Only after all the tests are passed was it repainted and then packed for shipping back to the customer. Most of our customers call these motors rebuilds, but in reality the level of precision and high standards that we use actually earn them the label re-manufactured.

The result was a final drive that hasn't just been repaired, dealing only with the parts involved in the failure, but a final drive where every part has been inspected so that failures waiting just a few hundred hours down the road are addressed before they happen. Whereas a repaired final drive works until the next issue goes wrong, a reman final drive has been restored so that it meets -- and even exceeds -- the original manufacturer specifications.

Rebuilt vs Reman

We've written articles on rebuilt versus re-manufactured, with re-manufactured being the higher quality option. What we've noticed, though, is that most people still come to us looking for rebuilt motors. At Texas Final Drive, rebuilt and reman mean the same thing: a quality-driven, detail-oriented process that restores your final drive motor to better than original condition through the careful replacement and reconditioning of parts. However, rebuilt and reman don't mean the same thing with all companies, so keep that in mind.

We've written articles on rebuilt versus re-manufactured, with re-manufactured being the higher quality option. What we've noticed, though, is that most people still come to us looking for rebuilt motors. At Texas Final Drive, rebuilt and reman mean the same thing: a quality-driven, detail-oriented process that restores your final drive motor to better than original condition through the careful replacement and reconditioning of parts. However, rebuilt and reman don't mean the same thing with all companies, so keep that in mind.

A Final Drive by Any Another Name ...

... Would run just as well? If you purchase a rebuilt final drive from Texas Final Drive, know that you are actually getting a reman final drive. That means even higher quality, better performance, and a longer lasting solution for you machine, whether its Komatsu, Caterpillar, Bobcat, Mustang, Kubota, etc. When it comes time to replace your final drive, be sure to consider all your options.

Texas Final Drive provides best-in-class