Let’s quickly review how to troubleshoot a hydraulic pump by looking at common symptoms and discussing the causes -- and whether the issue is even related to the pump.

Here are a few other Shop Talk Blog posts you might find interesting:

- Preventative Maintenance and Compact Equipment

- 7 Quick Tips for Skid Steer Maintenance in Extreme Weather

- Results of Hydraulic Contamination

Just because symptoms emanate from your hydraulic pump doesn't mean you have to get the pump repaired or replaced.

Pressure Loss

For example, pumps get blamed for pressure loss. But keep in mind that pumps don’t generate pressure: they generate flow, and restrictions to flow cause pressure. So if there is an issue with low pressure, then we know that the pressurized hydraulic fluid found a path of least resistance.

A worn-out pump can be the source of the problem, but that’s not all. Another possibility would be a leak somewhere in the system. And unless there’s been a sudden drop in pressure accompanied by new noises from the pump, a leak is the most likely cause.

Nothing Coming Out of the Pump

If absolutely nothing is coming out of your pump, there can be several reasons:

- The pump driveshaft is broken

- The pump isn’t assembled correctly

- The pump hasn’t been primed (which could be inlet restrictions, not enough oil in the reservoir, or incorrect startup)

- The pump is being driven in the wrong direction

However, not all potential causes for a lack of flow involve the pump. When there is no flow, consider these possible causes as well:

- Not enough fluid in the reservoir

- A clogged inlet line

- A clogged reservoir breather vent

- Dirty filters

New Noises

No one wants to hear rattling or something similar coming from their hydraulic equipment. We’ve talked about noise in relation to final drive motors, but what about pumps? The most common causes are …

- Cavitation

- Air in the system

- Misaligned coupling

- Worn-out parts.

The only one that can be blamed on the pump is a worn-out pump, and while cavitation damages the pump, the pump isn’t the cause. We’ve talked about cavitation before and the serious damage it can cause. For pumps, cavitation is usually caused by a dirty inlet filter or some restriction in the inlet line.

Another problem not directly related to the pump is air in the system. And one of the issues with air is that it prevents lubrication from reaching critical surfaces. This will eventually lead to accelerated wear and premature component failure.

Air can enter a system in several different ways, including

- A loose connection in the inlet

- No hydraulic fluid in the pump when it starts

- Leaking shaft seal

- Low fluid levels in the reservoir

Coupling misalignments can also be problematic, and noise can be caused by parts that have worn out or been damaged.

Excessive Heat

If your pump runs too hot, that’s not a good thing. Heat means energy is lost, efficiency is going down, and something is wrong.

So let’s go over what can cause excessive heat in the pump. Cavitation, the arch enemy of hydraulic systems, can be one of the causes, and so can air in the fluid. Your pump will also heat up as critical components can become damaged by contamination or simply wear out. Excessive load on the pump can also lead to excessive heat. Finally, don’t forget that overheated hydraulic fluid can significantly contribute to excessive heat in the pump.

Conclusion

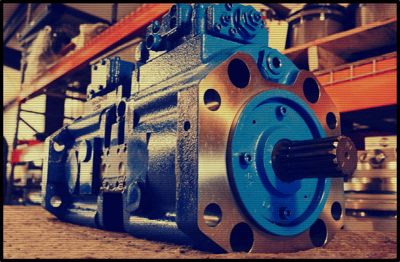

If you’re having pump problems, call us at Texas Final Drive, and we’ll try to help you troubleshoot. And if you need a new or reman pump for your SSL, CTL, or mini excavator, we can help you with that, too.