Bolts are critical to keeping your final drive motor together and running. In this Shop Talk Blog post, we're going to look at bolt preload and how it works.

Here are a few other interesting Shop Talk Blog posts you might want to check out:

- Hydraulic Contamination Failure Categories

- Loctite and Final Drive Motors

- Zombies and Remote Control CTLs and SSLs

Bolts are important fasteners in your final drive motor, and understanding the basics of how they work is always a good thing. Let's dive into bolt forces!

Bolt Forces

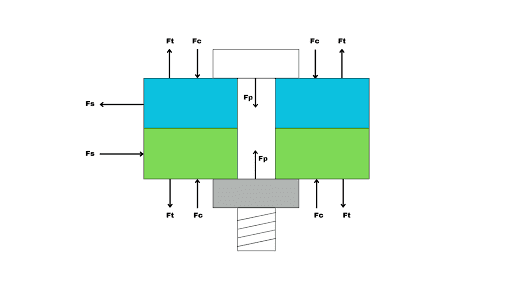

Consider the image below.

- Fp is the pre-load force

- Fc is the clamping force, which resists the tension force to keep the bolted joint together and is (usually) equal to the preload force

- Ft is the tension force, which is what tries to pull the mated surfaces apart

- Fs is the shear force, which can shear bolts apart if it’s high enough (and not our concern here)

While the nut is being tightened on the bolt, the forces reach a point where the bolt tries to stretch. But it is constrained by those surfaces so that it can’t stretch. Because it can’t stretch, a compressive load develops in the bolt called the pre-load (Fp). The pre-load then provides the clamping force, Fc, needed to hold the surfaces together.

Proof Load

You might have seen bolt specifications that include their proof load. Here’s an explanation from smartbolt.com

“Proof load is defined as the maximum tensile force that can be applied to a bolt that will not result in plastic deformation. In other words, the material must remain in its elastic region when loaded up to its proof load. Proof load is typically between 85-95% of the yield strength.”

Can bolts actually be pulled apart? They absolutely can. I was responsible for the mechanical engineering material testing lab at the University of Texas at Tyler, where we regularly ran experiments to study what happens when we pull bolts apart. When a bolt breaks, you’ll hear a pop--probably not as loud as you’d expect.

Here's a great example of a tensile test that Military & Commercial Fasteners Corp performed on a large, high-strength bolt.

Example: Calculating Proof Load

Let’s take a Grade 8 bolt as an example. Its tensile strength (which is often synonymous with its yield strength) is 150 ksi. That means its proof load is between 127.5 and 142.5 ksi. This ensures that the clamped parts remain in contact and in compression while avoiding yielding of the bolt material.

Recommended Preload

Ideally, when it comes to your final drive motor, you should use the manufacturer-recommended preload and torque. If you base the preload off the material’s yield strength, most engineers recommend It is 64% - 77% of the yield strength. For the Grade 8 bolt just discussed, 96 and 116 ksi. Note that this is less than the proof load. Other engineers recommend 80% of the proof strength. Oh, and you can find a great calculator for finding the preload at Bolt Torque & Preload Calculator | MechaniCalc.

Now here's something interesting to consider:

- Approximately 90% of the applied torque is employed in overcoming friction

- About 50% occurs at the bearing face of the nut

- Around 40% occurs between the mating threads

- Only about 10% effort is employed to induce axial load in the bolt

Conclusion

Bolt forces are more than just the force it takes to hold two things together -- it includes preload force, clamping force, tension force, and sometimes, shear force. However, the preload is crucial.