Not all contamination related failures are catastrophic --

but if the symptoms are ignored, they will be!

Here are a few other Shop Talk blog posts you might be interested in:

- Contamination Issues in Newer Machines

- Preventing Hydraulic Contamination

- Hydraulic Drive Motors and Contamination

Hydraulic contamination is a leading cause of failure in hydraulic systems and their components, including the drive motors for your compact equipment. The more you know about how these failures occur, the faster you can recognize problems before they get serious.

Hydraulic Contamination Failures

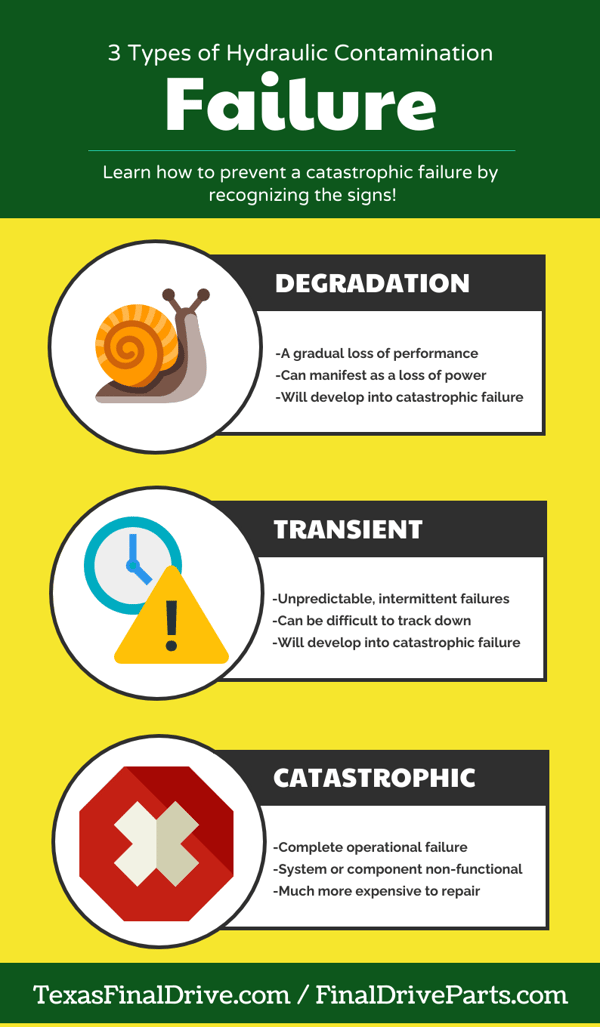

There are three categories of failure related to hydraulic contamination: degradation, transient, and catastrophic.

Type 1: Degradation Failure

Degradation failure manifests as gradual changes that take place over an extended period of time. This type of failure often takes the form of surface wear and has its greatest impact on clearance-critical parts such as pistons and valves.

If you own a skid steer loader, you might notice that it is pulling more and more to one side, or perhaps the arms cannot keep a load as high as they once did. You will usually notice a loss of power. Degradation failures can turn into catastrophic failures if their symptoms are ignored.

Type 2: Transient Failure

Transient failures are unpredictable, intermittent failures that are related to hydraulic contamination but can be very difficult to track down. For example, one of the drive motors on your compact excavator might randomly lose some power for just a few minutes or the bucket may be randomly slow to curl.

The cause of this type of failure is often trapped particles in parts such as valves. Transient failures often act as a red flag that there is contamination within the system. If left unaddressed, transient failures can soon turn into catastrophic failures.

Type 3: Catastrophic Failure

Catastrophic failure is the one we all dread: a complete failure of a component (i.e., final drive motor, main pump, charge pump) or the hydraulic system as a whole. Once a catastrophic failure has happened, things come to a grinding halt (literally and figuratively).

Of the three categories of contamination related failures, these are the most expensive, both in terms of repair costs and downtime. Catastrophic failures also seem to occur at the worst times, like when an important deadline is looming or if a project has already fallen behind.

Conclusion

If you notice the symptoms of degradation or transient failure, be sure to follow up on them before they turn into a costly and inconvenient catastrophic failure. However, it’s even better to try to minimize the chances of contamination entering your system through regular maintenance, only opening up the system and/or its components in clean environments, and being careful to use clean hydraulic fluid.