When a drive part is just too torn up, sometimes you just have to make your own!

Here are a few other Shop Talk Blog posts you might be interested in ...

Can You Machine Replacement Parts for a Final Drive?

There are times when a component in a final drive is just too torn up to repair or reman. You could buy a new or rebuilt replacement part -- but that isn't the only option. Depending on what part it is and what its made form, you could machine a new one.

Milling and Turning

Machining refers to a group of metal removal processes that create a part by cutting or grinding away the metal that is not needed. Milling is a machining process that uses a rotating cutting tool to remove metal until the final part shape is achieved.

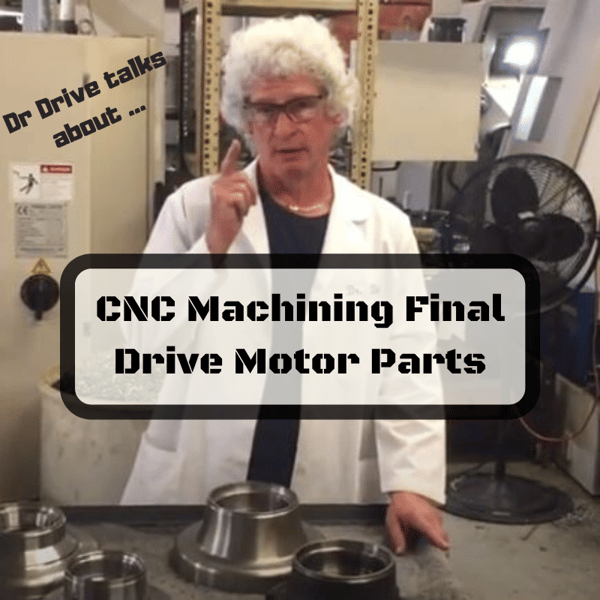

Turning is another machining process that is similar to machining but because it is used to generate cylindrical parts, too. While milling moves the part while the cutter rotates, in the turning process it is the cutter that is moved while the part rotates. A CNC lathe is shown below, with our own Dr. Drive.

In the past, a skilled operator named a machinist was responsible for the entire process -- selecting the speed and feed, depth of cut, and appropriate tool as well as loading the cutting tool and using it to make highly precise tool passes. However, the responsibilities of a machinist have changed.

CNC Machining and Turning

CNC machining and turning still requires a skilled machinist, but the machinist is no longer responsible for manually controlling the tool passes. Instead, he or she programs the tool passes into a program using a combination of G-codes and M-codes. Thanks to CAD/CAM (Computer Aided Design / Computer Aided Manufacturing), parts of the G-code can be generated from 3D models of the desired part.

The G-codes tell the milling machining where to move the part (usually in terms of X, Y, Z coordinates) and how fast it is too be moved (feed). M-codes deal with miscellaneous commands that can include tool changes, coolant flow, compressed air to remove chips, and to signal the beginning and end of a program. For parts such as hubs and main housings, a combination of machining and turning is needed to produce the final part.

CNC Machining and Final Drive Motors

Harnessing the power of CNC machining and turning allows us to make our own parts in house -- and make them even stronger. In the video at the beginning, our own Dr. Drive talks about how our machinist Mike uses CNC machining to make hubs for Bobcat T300s and and Bobcat T190s.

One of the hubs in the video was cast in-house and then CNC machining was used to achieve the precise geometry and dimensions for the inside. Another one of the hubs shown was fully machined, all from one piece of stock. It makes for a heavy hub, as Dr. Drive points out, but it is solid and durable. In addition to the hubs shown in the video, our machine shop has also machined main housings.

Conclusion

At Texas Final Drive, we are always looking for ways to leverage technology to improve the performance of your final drives. This just one example of how we do that. If you need your final drive motor repaired or rebuilt, contact us today.