We know that some of our readers like to work on their own final drives, and some of you may work in a hydraulics or heavy equipment maintenance shop where you encounter final drives on a regular basis. In this Shop Talk Blog post, we present four tips from final drive motor pros that you can put into practice the next time you have to work on a final drive hydraulic motor.

Practice Cleanliness in Your Shop

If you want to take good care of your final drive motors, you need to have a clean work space. That starts with cleaning your final drive off before you open it up. We follow a strict cleaning regimen that includes using an air needle scaler to get crusted debris loosened up, following by steam cleaning and then sand blasting. The work areas are kept clean, and we make abundant use of clean, disposable, lint-free shop towels. We are careful with everything that could come into contact with a customer’s final drive: tools, work surfaces, hoses, testing equipment, and parts storage are all kept clean.

So why the emphasis on cleanliness? One word: contamination. Contamination in the hydraulic fluid or the gear oil can total a final drive faster than you can imagine. If you open up the hydraulics side of your final drive in an environment that is filled with dirt, grime, and grease, you run the risk of introducing that same junk into your system. Grit, sand, metal shavings, etc. can do untold damage before they are trapped by a filter. You’ll notice we referred to using lint free cloths: threads and lint from rags can become harmful contamination, too. Tools, hoses, grease, and floors can all be sources of contamination. They key is to stay in control of the environment where you’ll be opening up a final drive and keep it clean.

Make Use of Squeeze Bottles

Trying to add fluid to a final drive can, admittedly, get messy. Many professionals invest in inexpensive plastic squeeze bottles like the one you see our own Dr. Drive holding. You can get them with graduated measurements on the side so that you can measure out the precise amount of fluid -- whether its hydraulic fluid, gear oil, or some other type of lubrication -- so there is no waste. It minimizes spillage (and the mess that can result) and lets you put the fluid exactly where you need it because of the small tip. This also works great for things other than your final drives -- like lube for axle bearings.

Replace Seals

Replace Seals

As our own Dr. Drive is known to say, “There is no leak that is going to fix itself.” If a final drive hydraulic motor has a bad seal, that seal is going to need to be replaced. Whenever we tear down a final drive motor, whether its for a repair or a full rebuild, we always replace all the seals. Those seals have a finite life -- they will not last forever. Removing them improperly can damage them to the point that they don’t seal much of anything in or keep much out, either. When you are taking a drive apart for service, go ahead and replace those seals as well.

Multiples

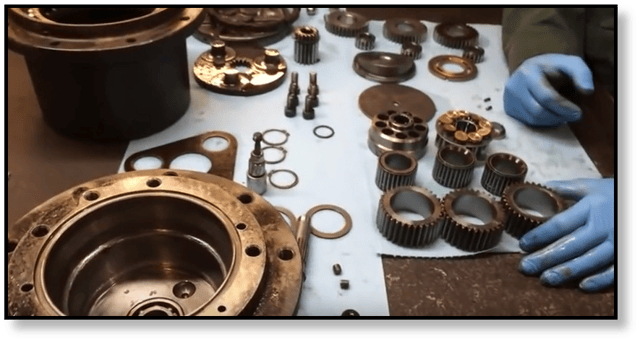

If something is installed in multiples, it should be replaced in multiples. Take, for example, the planetary gears in a planetary gear set. They are usually installed in multiples of three or four. Let’s say you opened up your final drive and noticed one of the gears was in poor shape. You should replace all three gears at the same time, not just the gear that is showing signs of wear. They were designed to be installed together. If you add a brand new gear to the mix then you could make the wear on the other gears even worse and just exacerbate the problem.

Conclusion

Cleanliness is vital for hydraulic motors, so remember to clean off the outside of the final drive before you open it up, and try to only open it up in a clean work space. Invest in new seals any time you disassemble your final drive motor. To minimize spills and waste, try using plastic bottles for adding fluids like gear oil and lube to your final drive. Finally, if something is installed as a set, replace the entire set. And don't forget your final drive maintenance.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.