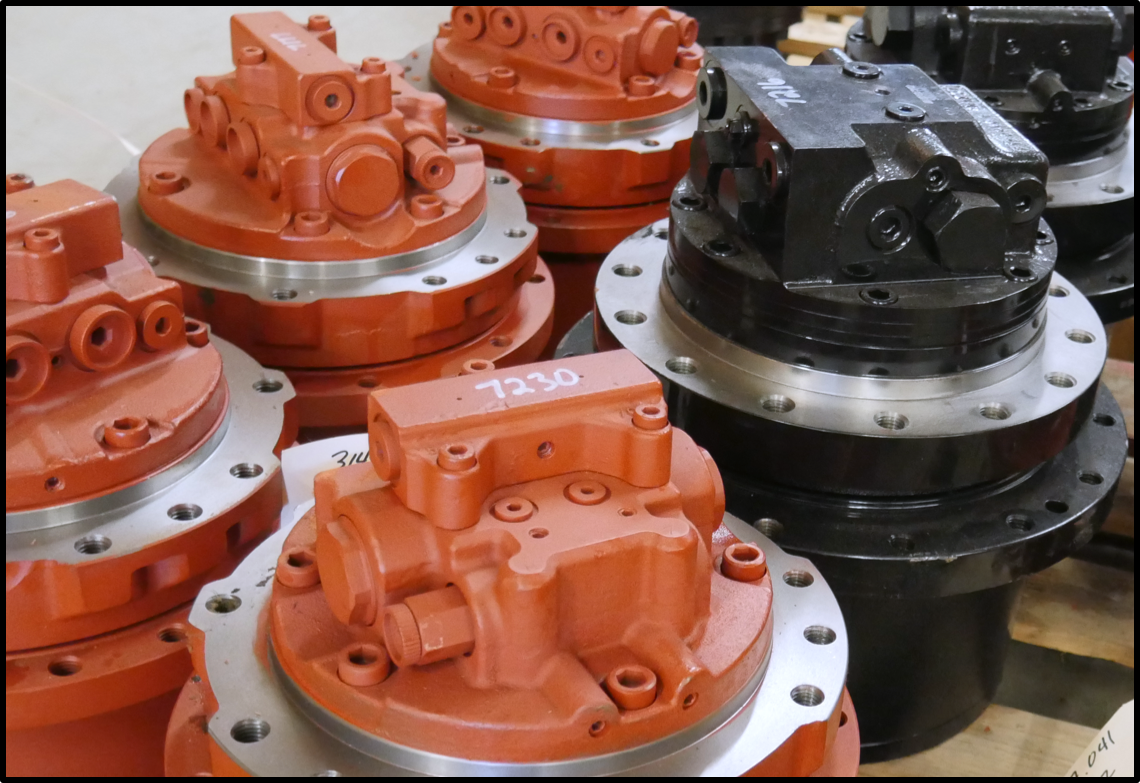

You've got quite a bit of money invested in your final drive motors, and when they go down it impacts your entire operation and your bottom line. In this Shop Talk Blog post, we'll review common symptoms of final drive problems, what they mean, and how to troubleshoot them.

What's Wrong With My Final Drive Motor?

Maintenance, Final Drive Diagnosis, Final Drive Problem

|Guidelines to Final Drive Maintenance

Final Drive Maintenance, Maintenance, Preventative Maintenance, Predictive Maintenance

|Here at Texas Final Drive, we often seen first-hand what poor maintenance can do to an otherwise good hydraulic final drive motor. In this blog post, we are going to review the WHAT, WHEN, and HOW of good final drive maintenance.

We understand that fleet managers face the challenge of reducing costs as much as possible. Premature repair costs can pack a huge punch, especially when you're in the middle of a job. The point that we always try to hammer home is that maintenance should not be ignored. In this Shop Talk Blog post, we are going to discuss six shop policies that you can put in place to aid in minimizing your maintenance costs.

Impact of Working Conditions on Your CTL / MTL Undercarriage

We’ve talked before about how 50% of your O&O costs are tied to the undercarriage of your CTL / MTL. In this Shop Talk Blog post, we are going to discuss the impact of underfoot conditions, operating techniques, and typical applications on the undercarriage. We also talk about how a little bit of job site planning can go a long way in helping to reduce wear and tear on your heavy equipment.

Generated Contamination in Final Drive Motors

Maintenance, Preventative Maintenance, Final Drive Problem, Contamination

|Bearings, axles, and gears inside a hydraulic final drive motor can be seriously damaged by abrasive contaminants in the lubrication or hydraulic fluid. However, many people don’t realize that all final drives generate contaminants as part of their regular use. In this Shop Talk Blog post, we are going to discuss generated contamination in your final drive motor, as well as how to keep that contamination to a minimum.

Skid Steer Maintenance Challenges in Agriculture

Skid steers have become a fixture on modern farms. With the attachments available today, skid steer loaders have become very versatile and are used for all kinds of different tasks. With their compact size, maneuverability, and power, they have become invaluable for the day-to-day operations of running a farm. When used in an agricultural setting, however, there are some special maintenance challenges that need to be addressed.

What the Best Final Drive Pros Do (and You Should Too)

We know that some of our readers like to work on their own final drives, and some of you may work in a hydraulics or heavy equipment maintenance shop where you encounter final drives on a regular basis. In this Shop Talk Blog post, we present four tips from final drive motor pros that you can put into practice the next time you have to work on a final drive hydraulic motor.

Hydraulic motors keep your fleet running -- whether you've got a full-size excavator with a track drive motor, a compact track loader with a final drive motor, or a skid steer loader with a propel motor. When any hydraulic motor fails, the rest of the machine won’t move. Here are three major things that fleet owners need to know regarding hydraulic motor failure.

4 Things to Remember about Filters in a Hydraulic System

Final Drive Maintenance, Maintenance, Filters, Case Drain Filters, Hydraulic Filters

|Although hydraulic filters are not a common topic, they are an important part of your hydraulic system. Failure to use them correctly can impact every component of your machine, right down to your final drive motors. In this Shop Talk Blog post, we are going to talk about some important things to remember about filters in a hydraulic system.

Caring for Your Equipment After a Flood

Heavy Equipment, Heavy Equipment 101, Heavy Equipment Safety, Maintenance

|With all the flooding that took place in the Houston area this year (as well as many other places around the world), flood damage is at the forefront of many people's minds. With that in mind, here are some general guidelines to help with assessing your equipment after it has been subjected to flood waters.