It always seems like final drives decide to fail at the worst possible moment, and when that happens, you usually have to make some quick decisions about a replacement. One of those options available to you would be reman (remanufactured) final drive motors, but used final drives are another. Which one is the best?

Discover the key differences between remanufactured and used final drive motors and why reman is a better option.

Here are some other Shop Talk Blog posts you might find interesting:

- Your Worst Nightmares About Final Drives Come to Life

- 6 Sure Ways to Sabotage Your Final Drive

- Unusual Excavator Accidents

What Are Reman Final Drives?

Reman final drives, short for remanufactured final drives, are final drives that have been restored to like-new condition. This process involves disassembling the final drive, inspecting and cleaning all the parts, replacing worn or damaged components, reassembling the drive, and thoroughly testing it. The result is a final drive performing just as well as a brand-new one, if not better.

At Texas Final Drive, we have the expertise and knowledge to ensure that the reman final drives meet or exceed the original equipment manufacturer's (OEM) specifications. As a result, reman final drives are known for their reliability and durability.

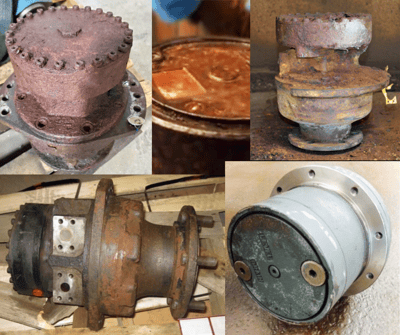

Exploring Used Final Drive Motors

On the other hand, used final drive motors have been previously used and removed for equipment. These motors may come from various sources, including salvaged equipment or machines that have been retired or replaced. Unlike reman final drives, they have not undergone the same rigorous remanufacturing process and may not have even been repaired.

While used final drive motors may still be functional, certain risks are associated with choosing them over remanufactured ones. Used motors can have unknown histories and may have been subjected to wear and tear, potentially leading to reduced performance and reliability. Additionally, the lack of a comprehensive remanufacturing process means that the used motors may not have been thoroughly inspected or repaired, leaving potential issues unresolved.

Cost Considerations

Cost is another important factor when deciding between reman and used final drive motors. Remanufactured final drives may have a higher upfront cost than used motors. However, reman final drives can be a more cost-effective option when considering the long-term costs.

Reman final drives are built to last and perform like new. They are backed by warranties and are often subjected to rigorous testing to ensure their reliability. This means they are less likely to require frequent repairs or replacements, saving you money in the long run. On the other hand, used motors may have a lower upfront cost but can incur higher maintenance and repair costs over time.

Quality and Reliability Comparison

One of the key differences between reman and used final drive motors is the level of quality and reliability. Reman final drives undergo a meticulous remanufacturing process that ensures all components are thoroughly inspected, repaired or replaced, and tested to meet stringent quality standards. This process helps to eliminate any potential issues and ensures that the final drive operates at optimal performance.

.jpg?width=400&height=329&name=8-quality-control-1st%20step%20after%20assembly%20%2cPressure%20Testing%20(1).jpg)

Used final drive motors, on the other hand, lack this comprehensive remanufacturing process. While they may still be functional, there is a higher risk of encountering performance issues or premature failure. The unknown history and potential wear and tear of used motors make them less reliable than remanufactured ones.

Environmental Impact

Choosing remanufactured final drive motors also has a positive impact on the environment. By opting for reman drives, you contribute to reducing waste and conserving resources. Remanufacturing involves reusing and refurbishing existing components, which reduces the need for new manufacturing and the associated consumption of raw materials.

![]()

Also, remanufacturing helps minimize the disposal of used final drive motors, preventing them from ending up in landfills. By extending the lifespan of these components, reman drives contribute to a more sustainable and eco-friendly approach to equipment maintenance and replacement.

Conclusion

At Texas Final Drive, we want you to get the best possible quality for your money. That's why we work to offer you the best prices on new aftermarket and reman final drive motors. Fill out a request for quote today!