Your mini excavator is the key piece of equipment in a major project with a very fussy client. Everything is going according to schedule, and it looks like there will be no problem in meeting the deadline coming up in just two days. That is, until something whizzes by you while you're inspecting some recent work on site. You rush over there to take a look at what flew by and recognize it as the cover plate off the travel motor on your excavator. Your worst nightmare about final drives and travel motors has just come to life.

.jpg?width=600&name=Add%20heading%20(1).jpg)

Here are a few other posts you might find of interest ...

- Preventing Case Drain Related Failure on Final Drives

- Bobcat 337 Final Drive Failures

- Cam Ring Failure in a Final Drive

Everything Comes to a Grinding Halt

You turn to look at the excavator, and it has literally stopped dead in its tracks. The operator is waving you down frantically. You can feel your blood pressure rising, and even though you don’t have on a tie it feels like you have a tourniquet around your neck. Your whole crew has taken a sudden interest in the excavator, and you have to elbow some of them to get out of the way in order to reach the operator. He’s on the ground now, next to the tracks on the left-side of the machine, gesticulating wildly and pointing to the track drive that’s missing its cover plate.

You are no mobile equipment mechanic, but you know enough to realize that this is very, very bad.

Questions Begin to Fill Your Mind

There are about a thousand thoughts running through your head: why couldn’t that motor have lasted just two more days? What on earth went wrong with that travel drive? How is the client going to react? What are you going to do? Why are your sweating likes it mid-summer when it’s chilly outside?

What on Earth Went Wrong?

We can’t answer most of the questions that would be running through your mind in that scenario, but there is one we can definitely answer: what on earth went wrong with that travel drive.

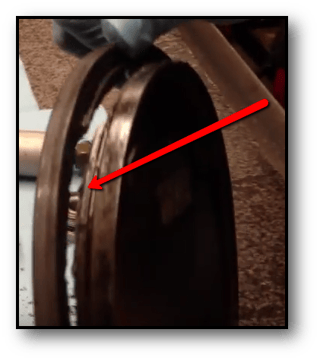

The source of the problem can be traced back to a small component called a case drain filter. It is an in-line filter located on the case drain line. When it's in good condition, you never even realize it's there. When it is in bad condition, it can literally destroy an otherwise good final drive motor. If you remove it and it looks like the one in the picture, then you checked it just in the nick of time.

The Culprit: A Clogged Case Drain Filter

Here’s what happened: the case drain filter clogged, causing an increase in pressure in the otherwise low pressure case drain line. As that pressure increases, there is also an increase in pressure inside the hydraulic motor. That pressure continues to build, looking for an easy way out. It finds it: the oil seal between the hydraulic and planetary sides of the hydraulic motor.

The oil seal blows, allowing highly pressurized hydraulic fluid to flood the planetary hub. The release in pressure was just momentary, however, because once again the high pressure fluid doesn’t have anywhere to go. Pressure continues to build as bearings and other parts inside the travel motor are being forced out of their normal positions by the pressurized fluid. Maybe the main seal starts to fail, but the pressure is so high that even that doesn’t provide much relief.

Boom! The cover plate either cracks or flies off. The travel motor is totaled.

Replace Case Drain Filters Regularly

Don’t let this series of unfortunate events happen to you. Replace that case drain filter whenever your replace the other filters on your equipment. It can help you avoid your worst nightmare and will save you a great deal of grief. It's cheap to replace, but saves thousands in repair costs.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.