We make money off final drives that no longer work, but we hate to see an otherwise good final drive fail because it wasn’t maintained properly. Here are five final drive maintenance tips to help you keep your final drive maintained and performing well.

Here are a few more posts you might find of interest ...

- Guidelines to Final Drive Maintenance

- Final Drive Maintenance with Dr Drive!

- Preventing Case Drain Related Failure

Tip #1: A final drive doesn’t exist in a void.

Your final drive does not exist in its own world. It interacts with your hydraulic system, which means that a failure upstream can impact the performance of your final drive and that a failure in your final drive can affect components downstream from it.

That is why it is important to check for other areas that might be causing your final drive motor to not function correctly, such as charge pumps, brakes, and tight tracks. And also why you need to maintain the rest of the hydraulic system.

Tip #2: Try to keep the work area clean.

This tip is referring to the area where you plan to open up your final drive -- and you really shouldn’t open one up in the field unless you can put down some clean cardboard or plywood and keep dust and dirt away.

Contamination will reduce the efficiency and performance of your final drive, and if you open up a final drive then you run the risk of introducing contamination and seriously damaging it. And many newer machines have a very low tolerance for contamination.

Tip #3: Plug ports and hoses.

Even if you don’t open up your final drive in the field, there is a good chance that you will have to disconnect the hydraulic lines at some point. Before you do this, take a couple of minutes and clean around those ports, then plug the ports and hoses with something clean (e.g., a clean lint-free rag or, better yet, a hydraulic plug). This will not only minimize the mess you make with hydraulic fluid but will keep contamination out of your final drive motor.

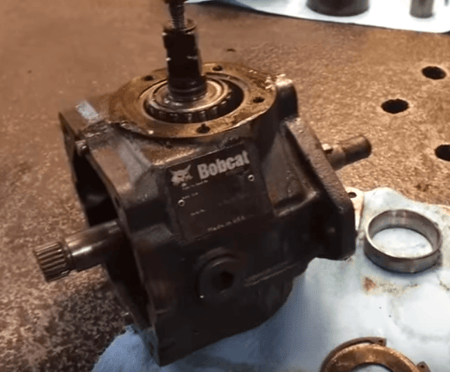

Tip #4: If you have a case drain filter, check it.

We cannot emphasize this enough: if your machine has a case drain filter (like many Bobcat machines do), then you need to replace it when you replace all your other hydraulic filters. It may seem like a lot of trouble, but this simple maintenance step can save you thousands (and we are not exaggerating) in repairs. If it ends up clogged, like the one shown in the image above, your final drive can end up totaled. Pressure will begin to build up on the planetary side, blowing seals and eventually allowing hydraulic fluid to mix with your gear oil. It is not uncommon for cover plates to crack or blow off under the kind of pressure that results.

Tip #5: If it leaks, fix it.

Here’s another tip you probably get tired of hearing: if you have a leak, not only is important fluid leaving your system but contamination can get inside. Don’t ignore leaks -- they are not going to go away.

Leaks can lead to a destroyed final drive motor, especially if the leak is on the planetary side. If most of the gear oil leaks out, you’ll be running those planetary gears and bearings dry and they will be damaged beyond repair. That is also why you should check and change gear oil levels on a regular basis.

Conclusion

If you want your final drive to last, then make sure to maintain it well. Any time and money you invest in the maintenance of your hydraulic motors is not a waste but instead results in lower overall M&O costs and reduced downtime. Don’t neglect your final drives -- they work hard for you.