Your excavator is a vital part of your work, and you know that if the track drives go out that excavator will not be moving anywhere. That’s why we have put together a list of tips to help you keep those track drives running!

Here are a few other Shop Talk Blog posts you might enjoy ...

- Eaton Track Drive Motors for Construction

- 3 Common Misconceptions about Excavators

- 5 Simple Keys to Effective Undercarriage Maintenance

Don’t dig over the track drive motors

Instead of digging over the final drive motor, you should dig over the front idlers. Digging over the final drives will put unnecessary stress on them, increasing the rate of wear and tear they experience. The idlers will also experience increased wear and tear, but they are much, much cheaper to replace. While there may be instances where it is necessary to dig over the finals, that practice should be avoided as much as possible.

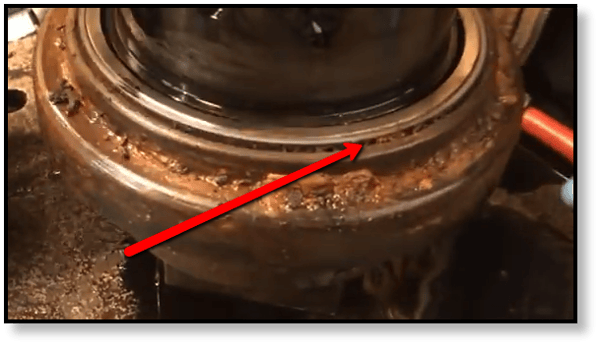

Keep the undercarriage and tracks clean

Keeping the undercarriage and tracks clean doesn't just keep your excavator looking nice but will help improve overall performance. Debris that is allowed to accumulate in and around the tracks, idlers, rollers, and track drive motor will start to add additional weight to the machine, increase the wear of track components, and affect track tension. In a worse care scenario, impacted debris can actually begin to displace the seals on a final drive motor. This not only causes leaks but will result in the ingress very damaging debris into your final drive motor. Taking the time to clean out the undercarriage and tracks will save you money over the long haul.

Replace the sprocket when teeth have worn to points

The sprockets on your excavator track system are made to be as rugged as possible. They are not only exposed to the debris your excavator faces on a daily basis, but they transmit thousands of ft-lbs of torque. That means the teeth on the sprocket are going to be the area of wear. Once those teeth start looking more like sharp points than rectangles, then it is time to change out that sprocket for a new one. Sure, the tracks will still turn … but you won’t be able to use the full power of your track drive motors, your machine will waste fuel, and you’ll probably increase the wear on those expensive track drives.

Make sure the track tension is set correctly

The track tension on your excavator will have an effect on your track drive motors along with the rest of the track components. If the tights are too tight, they can cause your final drive motors to seem weak when there is nothing wrong with them. Tight tracks will also cause the idlers and rollers to wear out faster than they should. Tracks that are too loose, on the other hand, can also speed up the wear of parts including the sprocket.

Conclusion

Your track drive motors are critical to the operation of your excavator, and one of the more expensive components to replace. However, you can extend their expected life and get optimal performance out of them by following a few simple rules, such as not digging over the final drives, keeping the undercarriage and tracks clean, replace worn out sprockets, and making sure the track tension is set correctly.