Overheating is one of the earliest warning signs that something inside your final drive is going wrong. Before you hear grinding or experience a total failure, a steady rise in temperature often signals problems that you can catch early if you know what to look for.

In this Shop Talk Blog post, we’ll talk about what is considered too hot, then discuss the five key reasons why final drives overheat. We’ll wrap up with a quick review of what kind of damage overheating can cause and simple checks to address it.

Here are a few other Shop Talk Blog posts you might be interested in:

- Why Is My Skid Steer Acting Up?

- What Causes a Final Drive to Wear Out Prematurely

- Buying a Replacement Final Drive Motor

What “Normal” vs. “Too Hot” Looks Like

If you can’t hold your hand on the motor housing for more than a second or two, it’s trending toward the overheating zone. And if it hisses when you sprinkle some water on it, then things are getting serious. That all translates to temperatures above 200°F, and once you hit 230°F, the gear oil breaks down rapidly, seals soften or fail, and bearings and gears are going to undergo permanent damage.

So let’s talk about what causes your final drives to run hot.

Reason #1: Low or Contaminated Gear Oil

Gear oil is so vital to the operation of final drive motors. When components are starved for lubrication or the gear oil is contaminated, the result is going to be increased friction. More friction leads to more heat generation. And increased heat causes your gear oil to lose key additives, making it inefficient at best. This result is aging gear oil, which is natural but becomes accelerated in the presence of heat.

Gear oil contamination can quickly become a nightmare. It leads to accelerated wear on gears, bearings, and even seals, eventually resulting in a totaled final drive motor.

Symptoms of gear oil issues include a burnt smell, sluggish equipment movement, and noise from the planetary hub of your final drive motor.

Reason #2: Case Drain Line Problems

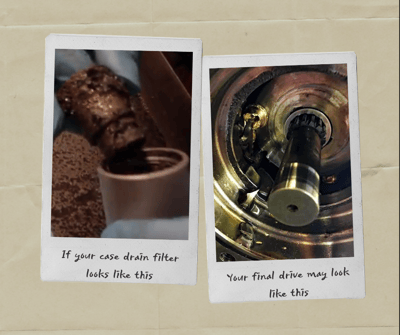

Another potential issue with an overheating final drive motor is case drain problems. The case drain relieves pressure in the final drive motor and helps with lubrication flow. When flow through the case drain line is impeded, the result is an overheated final drive. Common causes of case drain flow issues include a clogged line (usually due to a clogged case drain filter), kinked hoses that make flow difficult, or incorrect routing.

The results of case drain line problems include seal blowouts, overheating, and catastrophic failure.

Reason #2: Over-Tightened Tracks Increasing Load

If you’ve got a track machine, like a CTL or mini-excavator, excessive track tension can cause problems for more than just the track assembly. If the tracks are too tight, this overloads the bearings and creates additional resistance that the final drive motors have to overcome. There is a definite link between overheating final drive motors and tracks that are just too tight.

Track tension on compact equipment is easy to check in the field, but you should always consult the manufacturer's instructions and guidelines for your particular machine. For a CTL, lift the front of the machine, find the midpoint of the track, and measure the sag: most should have about 1 to 1.5 inches. For a mini excavator, lift one side with the boom and check the sag at the midpoint: typically ⅜"–¾". If there is no sag, the track is too tight and will overload the final drives.

Reason #4: Hydraulic Flow or Pressure Issues

Another potential cause of an overheating final drive is hydraulic flow and pressure issues. Consider this: low flow leads to cavitation that not only scores the components within your final drive motor but also leads to excessive heat generation. But excessive flow or pressure can cause problems as well. That kind of flow leads to overload conditions that cause rapid heat buildup.

This is also an example of how upstream pump and valve issues can masquerade as a problem only in your final drive motor.

You can spot hydraulic flow or pressure issues by watching how the machine behaves under load. If the final drive overheats even when track tension and gear oil levels are correct, or if the motor feels weak, jerky, or slow to respond, the issue may be upstream. Checking the pump output, system pressure, and valve performance can help you determine whether the problem is low flow, excessive flow, or pressure imbalance.

Reason #5: Internal Wear and Component Breakdown

Internal wear creates drag inside your final drive. This drag forces the final drive motor to work harder and generate excess heat. As internal components like gears, bearings, and splines deteriorate, they shed metal particles into the gear oil. This, in turn, further increases friction and accelerates the heat buildup in a seriously damaging cycle.

You can check for signs of internal wear by pulling the magnetic drain plug and checking for metal debris, as well as watching for leaks and listening for unusual grinding. These are all clear signs that internal wear is underway and needs to be addressed as soon as possible.

How Heat Damages Your Final Drive If Ignored

So let’s take a minute and summarize how heat can damage your final drive motors. Here are the four key problems involved:

- Breakdown of gear oil and loss of lubrication.

- Accelerated seal wear leading to leaks

- Spalling, scoring, and premature bearing failure.

- Risk of sudden failure on the jobsite.

Simple Field Checks to Diagnose the Source

Here are some simple field checks to run to diagnose the source of overheating:

- Check for leaks around the hub.

- Inspect track tension

- Verify the case drain line condition

- Check the hydraulic fluid condition and level

- Pull the magnetic plug to check for metal

Conclusion

Overheating is never something to ignore. It's your final drive’s way of telling you that something upstream, internal, or mechanical is putting the system at risk. By catching the warning signs early and addressing the root cause, you can prevent costly failures, extend the life of your equipment, and keep your jobs running on schedule.

If your final drive is running hot or showing signs of trouble, don’t wait: you can contact Texas Final Drive today for expert troubleshooting and reliable replacement options that keep you working instead of waiting.