Oil seals are used on the final drive motor axle to keep the gear oil for the planetary gear set or bearings from mixing with hydraulic oil. These seals are vital to the operation and performance of your final drive motor -- and learning how they can fail is essential.

Here are a few other Shop Talk Blog topics you might find helpful:

Oil seals are another key component in your final drive motor. They have a lip spring that closes the tension on the shaft to create a 1-way seal as the hydraulic side is the pressure side. This keeps the fluid from flowing past the seal into the gears or bearings, depending on the application.

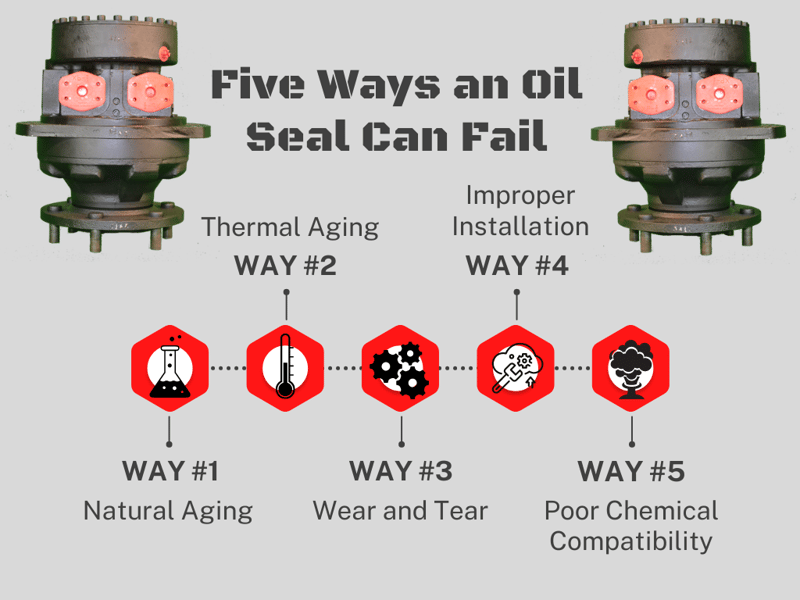

Way #1: Natural Aging

Oil seals can wear out in two ways: one is due to aging, and the other is caused by wear. Aging results from a chemical process that causes elastomeric seals to become brittle over time.

You may notice this when you’ve had a seal packaged and on your shelf for a long time. When you open the packaging and start to install it, it is brittle and cracks or splits. This is natural aging and is unavoidable. Aging also occurs while an oil seal is in service.

Way #2: Thermal Aging

The speed at which aging accelerates is related to temperature: exposure to high temperatures speeds up the chemical process behind aging. When seals become brittle and fail before they should, thermal aging is usually the cause.

Way #3: Wear and Tear

Oil seals naturally experience wear, and even the highest quality seals will wear out. For rotary seals, the lip comes in contact with a rotating shaft. Factors such as shaft finish, shaft hardness, contamination, and regular use play a role in the lip of the oil seal becoming too worn to keep the hydraulic fluid and gear oil separate. Seals like the one shown below (which is a face seal, however) will introduce serious, expensive contamination into your final drive motor.

Way #4: Improper Installation

This is a great video from The Mountaineer Mechanic that shows the correct process of replacing an oil seal on a pretty good sized Caterpillar. When installation is done improperly, however, it will contribute to seal failure. Here are some of the ways that improper installation can occur:

- Installing seals in the wrong direction, which defeats their purpose

- Using the wrong tools, which can damage seals or compromise their ability to seal

- Damaging the seals, which shorten their useful life and create paths for leakage

- Sharp corners in the seal groove, which can create paths for leakage

Way #5: Poor Chemical Compatibility

Oil seals must be compatible with the hydraulic fluid and gear oil used in your final drive. For example, Teflon seals resist otherwise problematic chemicals, but EPDM rubber isn’t very compatible with mineral-based oils. Likewise, if seals fail too quickly, but heat or poor installation isn’t the problem, there may be a chemical compatibility issue.

Conclusion

Pulling a seal that looks torn up will usually be normal wear or improper installation. If the seal is cracked or split, it will be either aging (natural or thermal) or poor chemical compatibility.

Here at Texas Final Drive, we know that seal failure has serious repercussions and can damage your final drive motor. Any time we open up a final drive, we replace the oil seals -- and the seals that we use in all our reman or repaired final drives are of OEM quality. And our replacements are not outdated seals that are ready to crack -- we don't hang onto expired seals.