If you’re going to work on a final drive motor or pump, it’s essential to set aside a clean workspace if you want to prevent contamination and the expensive damage it can cause. Here are some hints and tips to help you have a safe workplace for your hydraulics.

Here are a few other Shop Talk Blog posts:

- 7 Reasons Why You Should Keep Your Machines Clean

- Daily Maintenance for Skid Steers

- Duo Cone Face Seal Failure

Things to Have on Hand

Let’s start with some things that are good to keep on hand:

- Lint-free rags or disposable wipes

- Replacement seals

- Replacement filters

- Clean hydraulic fluid

- Clean lubricant

- Degreaser

- Compressed air

Another item to keep on hand is clean cardboard to plywood for when you have to open up a final drive in the field. And make sure your tools are clean!

Choosing a Work Area

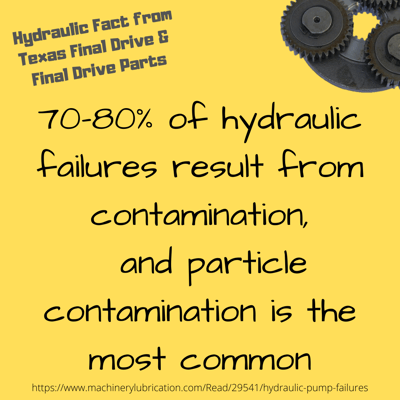

Choose a work area that is well away from grinding, machining, and welding. Metal chips, slivers, and particles are incredibly damaging when they make their way inside a hydraulic system. And let’s face it: when we’re using a grinding tool or machining, tiny bits of metal and abrasive can fly much farther than most people would expect. And if you use fans to keep cool, make sure any fans near the hydraulic work area aren’t positioned to pull in dust from the outdoors.

Keep the Work Surfaces Clean

Keep work surfaces free of dust, metal particles, dirt, sand, and grease. If something is on the work surface, it can get into your hydraulic motor. And don’t forget, if you have to open up a drive motor in the field, you can always use some clean cardboard or plywood for a work surface. We recommend giving that work surface a quick wipe down before you start working.

As you can see above, we try to keep the assembly workplaces as clean as possible. JThink about it this way: if you lay a seal down on a dusty worksurface before you install it, you're introducing those particles to the surface of the seal, which can impact its life and performance. And that same debris is going to end up in your final drive when you install that seal.

Lint-Free Rags

When working with components inside a final drive, only use clean, lint-free rags or disposable wipers. So why is this a big deal? Because tiny, soft particles are a form of contamination and can clog orifices, small passageways, and hydraulic filters -- and we all know that ordinary shop rags will shed.

In addition, make sure the lint-free rags used are soft so they won’t damage any critical surface finishes. Another good solution is using compressed air, as long as it's clean. However, lint-free rags can still catch on rough edges and tear, possibly leaving little pieces behind. So an excellent alternative to lint-free rags is a clean source of compressed air. Now, cleaning the exterior of a drive motor is a different story: use whatever you need to get it clean enough to open.

Be Careful With Storage

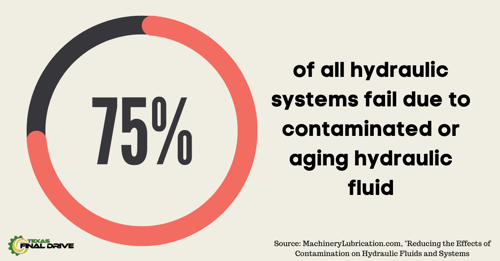

Keep hydraulic fluid stored in a temperature-controlled environment. Significant temperature changes can lead to a phenomenon called “breathing,” where containers can breathe in the moisture in the air. The container air can contract and suck in moisture when the temperature changes. If the containers have to be stored outside, lay them on their side so that water doesn’t collect on top.

And remember to keep your gear oil and hydraulic fluid containers closed when you aren’t actively using them. Contaminants, including dust, water, and air, can wreak havoc on exposed fluids and lubricants. And if hydraulic fluid and gear oil are exposed to high temperatures, they'll age much faster. This not only means a shorter useful life but the potential for damage.

Storage conditions don’ just apply to fluids. Keep replacement seals stored in a relatively cool, temperature-controlled environment where they are protected from extremes of heat and cold. Heat will accelerate the rate of aging, and the last thing you want to do is open up a replacement seal or O-ring package only to find them brittle.

Conclusion

A suitable hydraulics workspace doesn't mean semiconductor manufacturing level cleanliness with suits and gloves, but it does need to be as free as possible of problematic contaminants. We hope these hints and tips have reminded you of the importance of a relatively clean work area and have helped you setup your own.

And don't forget that if you've got a final drive motor that's been destroyed by contamination, we've new and reman final drives in stock today.