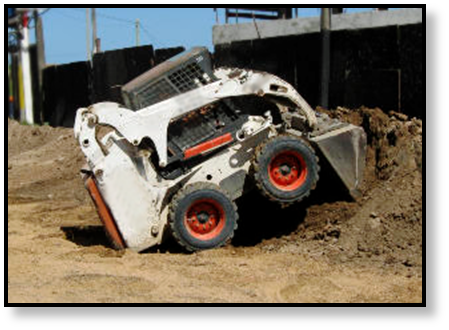

Skid steer loader backover accidents are scary for all involved -- and often fatal for the victim. Learn what they are, how they happen, and what you can do to prevent them.

Here are a few other Shop Talk Blot posts you might find of interest:

- Skid Steers Turned Deadly?

- Hydraulic Fluid Injection -- Do You Know the Dangers?

- Skid SteerSafety and Lift Arm Supports

Backover Accidents: What Are They?

According to the OSHA Fatality Inspection Data page, backovers and crushings are the most common fatal accidents with skid steer loaders for CY17-21. In fact, Backovers are such a problem in general that OSHA has an entire page dedicated to preventing them. And for clarity, here is the official OSHA definition: “A backover incident occurs when a backing vehicle strikes a worker who is standing, walking, or kneeling behind the vehicle.”

How Backovers Happen

Here are some of the common causes behind backover accidents:

- Blind spots

- Pedestrians and/or operators distracted

- Backup alarms missing or malfunctioning

- Too much background noise to hear backup alarms

Blind Spots

Iowa Farmer Today writer Brandi Janssen did an excellent article on blind sports for commonly used farm equipment. In this article, she points out that the rear corners, where the view can be blocked by the lift arms, are the most common locations for blind spots on a skid steer loader.

These particular blind spots can take up much of the available rearview for a skid steer and are very problematic. In addition, the height of the operator sitting in the loader can also affect the blind spots. This is why it is always a good idea to identify your blind spots in a machine before starting your work.

Distractions and Inattention

This could be an operator who fails to look in the direction of travel, a pedestrian with earbuds or headphones who fails to hear a backup alarm or simply preoccupied with something else.

But, of course, distractions and inattentiveness can have other causes, as well. Fatigue, sleepiness, stress, complacency, and frustration are among the reasons pointed out in an article on construction safety by Holt Cat.

Backup Alarms

Ideally, a backup alarm is supposed to let those around you know that you’re changing direction. This is important, especially if the people around you aren’t paying very close attention. The hope is that the beeping sound will attract their attention and remind them to watch out when you can’t always see what’s behind you. While it’s true that backup alarms don’t always accomplish this goal, that doesn’t mean they shouldn’t be used

And while OSHA doesn’t really state directly that backup alarms are needed on skid steers. However, they do indicate in Standard 1926.601(b)(4) that backup alarms are only required when “when vision to the rear of the operator is obstructed, and the operator lacks an observer to signal him.”

Preventing Backovers

Now that we’ve discussed how backovers happen let’s look at possible solutions.

- The first line of defense against such accidents is to stay alert. And this applies equally to operators and pedestrians.

- Never bypass or modify the safety devices on your skid steer.

- Make sure the backup alarm on your skid steer loader works. If it doesn’t have one, then get one installed.

- Add backup mirrors or additional cameras to help with your skid steer’s blind spots

- Consider installing proximity detection devices.

- Ensure that anyone on the worksite is wearing high-visibility clothing.

- Consider using traffic cones, fencing, or barrier tape to keep pedestrians out of your work area

- Make eye contact with those around you to ensure they are aware of you and your skid steer.

Conclusion

Here at Texas Final Drive, we never want to hear that one of our customers has become an OSHA statistic. We’d like to encourage you to be careful and take as many measures as possible to prevent backover accidents.