Lubrication Starvation in a Final Drive Motor

Lubrication, as we have discussed in previous posts, is a major investment in your equipment. You don’t need expensive diagnostic tests, however, to notice when something is going wrong with lubrication. In this short blog post, we are going to look at the primary symptoms of lubrication starvation in a final drive.

Lubrication, as we have discussed in previous posts, is a major investment in your equipment. You don’t need expensive diagnostic tests, however, to notice when something is going wrong with lubrication. In this short blog post, we are going to look at the primary symptoms of lubrication starvation in a final drive.

Here are some additional Shop Talk posts you might find helpful ...

- How to Destroy a Final Drive in 3 Easy Steps

- 3 Things You Should Know about Gear Oil for Final Drives

- 5 Reasons a Final Drive Can Lack Power

Heat

The first sign of major issues with lubrication is going to be heat. When there isn’t enough lubrication between two contacting metal surfaces, friction will increase. That increase in friction then generates heat. Lubrication is supposed to conduct the heat away from the key components in your final drive, but without enough lubrication the heat buildup will keep getting worse.

You might touch the final drive and notice it is abnormally hot, or the surface of the final drive hub or cover plate may steam when it comes into contact with water. This level of heat means you need to check on the fluid levels in your final drive right away.

Heat, however, is not just a symptom. Heat is a source of problems.

Welding and Galling

As heat builds, it can reach the point where the contacting surfaces begin to weld to each other, then the weld is broken and a tiny sliver of metal comes loose.

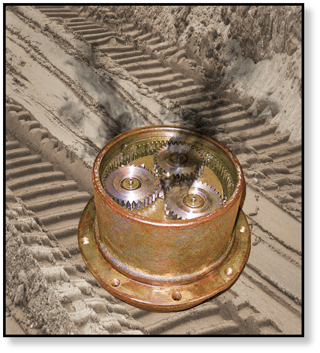

We’ve encountered damaged final drives that have gear oil filled with metal shavings, like the brass shavings you can see on the cover plate shown below. This is one of the ways that happens, and this destructive cycle is known as welding and galling. Once galling starts, it spreads very quickly. This vicious cycle, if allowed to continue, will destroy your equipment.

If you check the gear oil for your final drive and notice metal shavings, you need to change the gear oil and check for leaking seals.

Noise and Vibration

Another indicator of lubrication issues is going to be noise. For example, when the final drive on a machine begins to run very low on gear oil, the operator will likely notice some significant vibration, if not excessive or unusual noise. When equipment suddenly develops some new vibrations, it might be time to check the lubricant levels. In fact, lubricants act as noise and vibration dampeners.

Operators will be the first to notice issues with noise and vibration because they are accustomed to the way their equipment usually runs. Complaints or comments along these lines should never be ignored.

Conclusion

Proper lubrication is very important to your equipment, and especially to the final drives and hydraulic motors that power it. If you don't keep things lubricated properly, you will have something wrong with your final drive before too long. And it might be expensive to fix.