Multi Terrain Loaders and Compact Track Loaders

Many people use the terms multi-terrain loader and compact track loader interchangeably, but they aren’t the same. In this Shop Talk Blog post, we are going to discuss the difference between MTL's and CTL's and how those difference impact function and performance.

A CTL By Any Other Name …

Caterpillar (and ASV in the past) is the primary track loader manufacturer to use the term multi-terrain loader. Caterpillar, in particular, uses the term to differentiate from their compact track loader. Other manufacturers like Bobcat only focus on CTLs. The difference between the two, however, is more than just their names. It includes how they were designed, the type of terrain they work best on, and whether or not they can handle aggressive applications.

Undercarriage

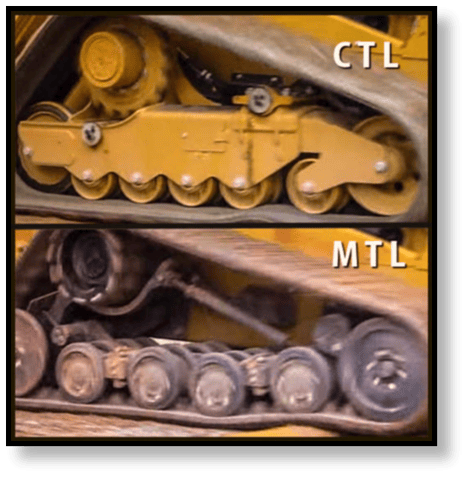

At first glance, multi-terrain loaders (MTLs) and compact track loaders (CTLs) look the same: the both use tracks, seem designed to serve the same purpose, etc. However, they were actually designed to do very different things, and the key to that design lies in differences in the undercarriage.

The undercarriage is a vital part of providing the floatation and tractive power of a MTL or CTL. In includes components like the tracks, chains, idlers, wheels, sprockets, and final drive hydraulic motors. It’s a complex system of interactive parts and mechanisms, and as we already pointed out, is the key difference between a CTL and a MTL.

Characteristics of an MTL

In a MTL, the undercarriage has been designed to have an extremely low ground pressure, even compared to a CTL. This is accomplished through items such as all rubber tracks, even weight distribution, and the use of lighter weight components, such as the rubber-coated roller wheels used on the Caterpillar MTLs. In addition, the undercarriage of an MTL is a suspended design, allow the tracks to maintain better contact with the ground when on very uneven surfaces.

In a MTL, the undercarriage has been designed to have an extremely low ground pressure, even compared to a CTL. This is accomplished through items such as all rubber tracks, even weight distribution, and the use of lighter weight components, such as the rubber-coated roller wheels used on the Caterpillar MTLs. In addition, the undercarriage of an MTL is a suspended design, allow the tracks to maintain better contact with the ground when on very uneven surfaces.

CTLs, on the other hand, are designed to have a stiffer undercarriage with a rigid (as opposed to suspended) design. The undercarriage components are designed for maximum wear with minimal concern for weight. They have been designed for rugged applications in areas where skid steers either can’t provide enough traction or would do too much damage.

Benefits of an MTL over a CTL

The lower pressure means that an MTL can work on very delicate surfaces. We know that a CTL is meant to work on more delicate surfaces than, say, a wheeled skid steer; however, the MTL is designed to work on even more delicate surfaces than the CTL (e.g., lawns, sod, etc.). The MTL can also travel faster and, according to operators, the MTL is a far more comfortable ride, too, because of its suspended undercarriage.

Drawbacks of an MTL

If you are going to be moving harsh materials or working on an unforgiving surface like gravel, the MTL is not an ideal choice, though. It is simply not meant for the same type of aggressive work that a CTL is designed to withstand. In addition, the rubber tracks will likely not last as long as the tracks on a CTL, which are often reinforced with steel cables.

Per Caterpillar, the CTL is definitely more rugged than the MTL and will most likely last longer, even though the specs may be similar. Part of this ruggedness is due to the rigid CTL undercarriage. That means that you will not get the same life out of an MTL is you try to use it like a CTL.

Conclusion: Design of The Undercarriage

The main difference between a CTL and an MTL lies in the design of the undercarriage: multi-terrain loaders are designed to be used on more delicate surfaces and with lighter loads than their brothers, the compact track loaders. Both have lower ground pressure and can work on more sensitive terrain than skid steers, but the MTL should not be used on unforgiving surfaces or for more aggressive applications unless you want to seriously reduce its useful life. If you need a more rugged, long-lasting machine, then opt for a CTL.

Getting the most out your compact track and multi terrain loaders means keeping your excavation equipment in maximum working order. Yet when equipment downtime happens partnering with the most cost efficience and time sensitive manufacturing source is key! Texas Final Drive provides the best-in-class resource for reman final drive motors. Check out the latest inventory updates for Bobcat Compact Track Loader Hydraulic Drive Motors.