It's essential to be careful when selecting a replacement hydraulic hose for your compact equipment.

Here are a few other blog posts you might find of interest:

- Five Things to Avoid Doing with Hydraulic Lines

- Identifying the Hydraulic Ports on a Final Drive Motor

- How to Destroy a Final Drive

Replacing a Hydraulic Hose

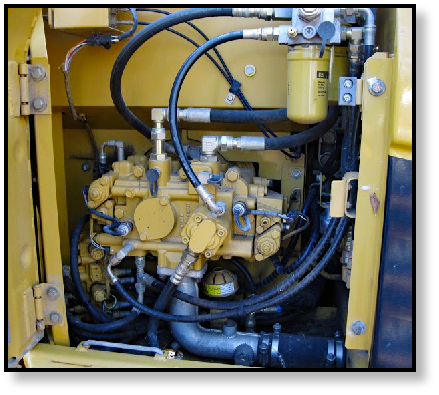

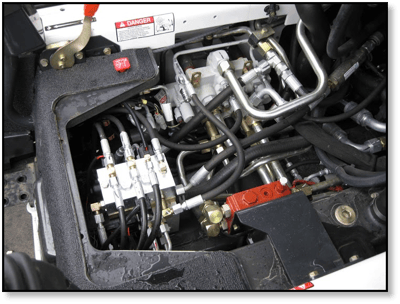

Maybe during routine maintenance of your skid steer loader or mini excavator you discovered a hydraulic hose that's starting to crack or is leaking. The key things to consider when replacing a hydraulic hose are …

- Pressure rating

- Inside diameter

- Outer diameter

- Bend radius

- Length

- Temperature

- Material

- Hose reinforcement

Another way of looking at hose replacement is to follow the STAMPED process from The Association of Hose and Accessory Distributors (NAHAD). STAMPED stands for Size, Temperature, Application, Material/Media, Pressure, Ends, and Delivery.

Let’s talk about each of these considerations separately. Before we start, though, note: if you hose on hand that you’re replacing, begin by using some precision calipers to measure the inside and outside hose diameters and take note of the fittings on the ends.

Pressure Rating

The maximum working pressure (WP) for a hose should be above the system’s normal operating pressure and account for temporary pressure surges. You should be able to track this information down from your equipment manufacturer.

Inside Diameter for Hydraulic Hoses

The inside diameter (I.D) of a hydraulic hose is the space in the cross-section of the hose and serves as the primary mode of sizing a hose.

If the I.D. is too small for the rate of flow you need, the fluid velocity will be high. That leads to higher friction, heat, and increased pressure, as well as a greater chance for leaks and excessive pressure drops. If the ID is too small, it can damage your hydraulic system. On the other hand, if the I.D. is too large, you’re likely to see sluggish performance. Luckily, manufacturers usually provide a table that shows the recommended diameter when you know the flow rate and the length of the hose.

Outer Diameter for Hydraulic Hoses

The outer diameter (O.D.) of a hydraulic is the diameter of the hose's exterior and includes the tube, reinforcement, and outer cover. The O.D. is key to sizing the hose to appropriate fittings and system components. Also, the thickness of the hose wall is the difference between the I.D. and the O.D.

Bend Radius

The bend radius refers to the minimum diameter that you can arc a hose. Using too small a bend radius can lead to several problems, including kinks, flow restriction, and causing larger gaps between reinforcement strands. Areas where strand gaps are farther apart can cause the hose to be more susceptible to failure and reduce the overall life of the hose assembly.

Hydraulic Hose Length

Let’s talk about why the hydraulic hose length is so important. First, it determines the maximum reach between the endpoints you need to connect. Second, the head loss that results from friction is determined in part by the length of the hose: the longer the hose, the more friction will be present and the greater the pressure drop. If you have the hose on hand that you’re replacing, measure its length.

Otherwise, determining the hose length is more than just measuring the distance between the endpoints you need to connect. For example, when figuring out the hose length, leave at least two hose widths of space between any bends and the crimp. And a good rule of thumb is to make the hose slightly longer than you need.

Operating Temperature

All hydraulic hoses have a maximum temperature of at least 200°F, and some range up to 400°F. Using a hose at a temperature greater than what it’s rated for will decrease its useful life, leading to premature hose failure.

Hose Material

First, ensure that the inner tube material is compatible with the hydraulic fluid you use. This is mainly a problem with biodegradable fluids or those designed to be “green.”

For inner tubing, materials include

- Buna-N (nitrile or NBR) is a synthetic rubber that offers excellent flexibility and is typically used for lower pressure applications.

- Teflon (also referred to as PTFE) is a fluoropolymer that is low friction, chemically compatible, can handle high temperatures, and has an excellent flex life when impulse loadings are involved.

- Thermoplastics are often used when kink resistance and a small minimum bend radius are needed. They are also very lightweight.

- Metal hoses can usually perform well when high temperatures and/or high pressures are involved, and they are available as either flexible or stiff.

The cover of a hydraulic hose is usually made from neoprene, fiber, vinyl nitrile, or synthetic rubber. When selecting a cover, be sure to think about exposure to UV light, ozone, abrasive materials, heat, and exposure to saltwater.

Hose Reinforcement

There are a few different kinds of reinforcement categorized on whether they use a braid or spiral approach to reinforcement. Wire braid is more flexible but not as strong. Wire spiral, on the other hand, is not quite as flexible but stronger.

The most common types are listed in ascending order of pressure rating.

- Single fiber braid

- Single wire braid

- Double wire braid

- Four-ply spiral

- Six-ply spiral

The fittings include the end style, method of attachments, and orientation. Your best bet is to use the same setup as the original or, if you don’t know what that was, the OEM standards or recommendations for your machine.

Conclusion

Finding the right replacement for a hydraulic hose is essential. The wrong one can impact your system's performance and even damage it. And this is true for the hoses that connect to your final drive motors, too.